Is HDPE plastic strong?

2024-10-11 15:22:20

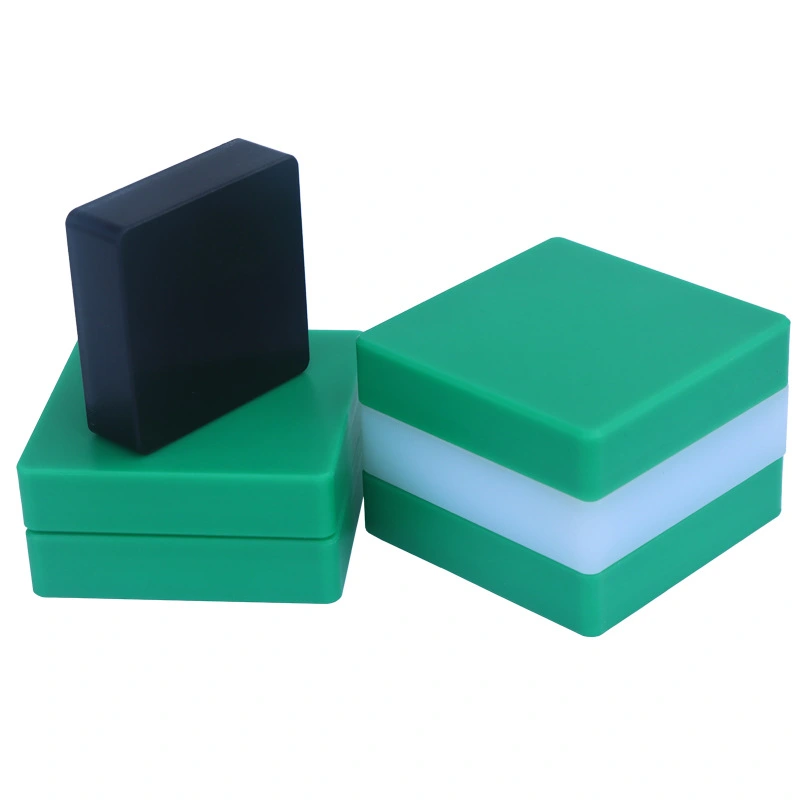

When it comes to selecting materials for various applications, strength is often a crucial factor. High-Density Polyethylene (HDPE) plastic has gained significant popularity across industries due to its unique properties. In this comprehensive guide, we'll explore the strength of HDPE plastic sheet, its applications, and why it's become a go-to material for many manufacturers.

Understanding HDPE Plastic

What is HDPE?

HDPE is a versatile thermoplastic polymer known for its high strength-to-density ratio. It's derived from petroleum and is characterized by its long chains of ethylene molecules. This structure contributes to its remarkable strength and durability.

Chemical Composition and Properties

The chemical composition of HDPE consists of repeating ethylene units. This arrangement results in a material with exceptional resistance to chemicals, impact, and environmental stress cracking. HDPE's molecular structure allows it to withstand high temperatures and maintain its properties across a wide range of conditions.

Manufacturing Process

HDPE is typically produced through a process called polymerization. This involves linking ethylene monomers to form long polymer chains. The manufacturing process can be tailored to produce HDPE with varying densities and molecular weights, allowing for customization based on specific application requirements.

Strength Characteristics of HDPE

Tensile Strength

One of the most notable attributes of HDPE board is its impressive tensile strength. HDPE can withstand significant pulling forces without breaking or deforming. This property makes it ideal for applications that require materials to bear heavy loads or resist stretching under pressure.

Impact Resistance

HDPE exhibits remarkable impact resistance, making it less prone to cracking or shattering upon impact. This characteristic is particularly valuable in environments where materials may be subject to sudden shocks or collisions, such as in industrial settings or outdoor applications.

Chemical Resistance

The strength of HDPE extends beyond mechanical properties. It boasts exceptional chemical resistance, remaining unaffected by a wide range of acids, bases, and solvents. This attribute enhances its durability and makes it suitable for containing or transporting various chemicals safely.

Applications of HDPE Board and HDPE Plastic Sheet

Industrial Uses

HDPE boards and sheets find extensive use in industrial applications. They're often employed in the construction of chemical storage tanks, industrial liners, and protective barriers. The material's strength and chemical resistance make it an excellent choice for environments where durability and safety are paramount.

Construction and Infrastructure

In the construction sector, HDPE boards are increasingly being utilized for various purposes. They serve as effective moisture barriers, insulation materials, and even as lightweight yet strong alternatives to traditional building materials. HDPE's strength-to-weight ratio makes it particularly attractive for projects where reducing structural load is crucial.

Consumer Products

The strength and versatility of HDPE board have led to its widespread use in consumer products. From durable cutting boards in kitchens to robust outdoor furniture, HDPE's ability to withstand wear and tear while maintaining its structural integrity has made it a popular choice among manufacturers and consumers alike.

Comparing HDPE to Other Materials

HDPE vs. Steel

While steel is traditionally known for its strength, HDPE offers several advantages in certain applications. HDPE is significantly lighter than steel, making it easier to transport and install. It also doesn't corrode or rust, giving it an edge in environments where moisture is a concern. However, steel still outperforms HDPE in terms of absolute strength and heat resistance.

HDPE vs. Other Plastics

Compared to other common plastics like PVC or polypropylene, HDPE often stands out in terms of strength and durability. It typically offers better impact resistance and can withstand higher temperatures without deforming. However, each plastic has its unique properties, and the choice often depends on the specific requirements of the application.

Environmental Considerations

When comparing materials, it's crucial to consider environmental impact. HDPE is recyclable, which gives it an advantage over some other materials. However, its production does involve petroleum, raising sustainability concerns. Ongoing research is focused on developing bio-based alternatives that maintain HDPE's strength while reducing environmental impact.

Factors Affecting HDPE Strength

Molecular Weight

The molecular weight of HDPE plays a significant role in determining its strength. Generally, higher molecular weight HDPE board exhibits greater strength and impact resistance. This is due to the longer polymer chains, which create more entanglements and stronger intermolecular forces.

Density

The density of HDPE directly correlates with its strength. Higher density HDPE typically demonstrates increased stiffness, tensile strength, and chemical resistance. However, this may come at the cost of reduced impact strength in some cases, highlighting the importance of selecting the right grade for specific applications.

Processing Conditions

The strength of HDPE can be influenced by the conditions under which it's processed. Factors such as cooling rate, extrusion temperature, and molding pressure can affect the material's crystallinity and orientation, which in turn impact its mechanical properties. Proper control of these parameters is crucial for achieving optimal strength in HDPE products.

Enhancing HDPE Strength

Additives and Fillers

Various additives and fillers can be incorporated into HDPE to enhance its strength and other properties. For instance, carbon black is often added to improve UV resistance, while glass fibers can significantly increase tensile strength and stiffness. The choice of additives depends on the specific requirements of the end application.

Cross-linking

Cross-linking is a process that can be used to further improve the strength and heat resistance of HDPE. This involves creating chemical bonds between the polymer chains, resulting in a more robust network structure. Cross-linked HDPE exhibits enhanced mechanical properties and can withstand higher temperatures without deforming.

Surface Treatments

Surface treatments can be applied to HDPE plastic sheet to enhance its strength in specific ways. For example, corona treatment can improve the material's adhesion properties, allowing for stronger bonding with other materials. Plasma treatment can increase surface energy, potentially improving strength in composite applications.

Testing HDPE Strength

Tensile Testing

Tensile testing is a fundamental method for evaluating the strength of HDPE. This involves subjecting a sample to a controlled tensile force until failure occurs. The test provides valuable data on the material's tensile strength, elongation at break, and elastic modulus, offering insights into its performance under load.

Impact Testing

Impact testing assesses HDPE's ability to resist sudden applied forces. Methods such as the Izod impact test or the Charpy impact test are commonly used. These tests help quantify the material's toughness and its capacity to absorb energy during high-speed fracture, which is crucial for many applications.

Environmental Stress Crack Resistance (ESCR) Testing

ESCR testing is particularly important for HDPE, as it evaluates the material's resistance to cracking under stress and in the presence of certain chemicals. This test involves exposing stressed samples to a specific environment and monitoring for crack formation. High ESCR is essential for applications where the material may be exposed to harsh conditions over extended periods.

Conclusion

HDPE plastic has proven itself to be a remarkably strong and versatile material. Its combination of high tensile strength, impact resistance, and chemical durability makes it an excellent choice for a wide range of applications. From industrial use to consumer products, HDPE boards and sheets continue to find new and innovative uses.

Contact Us

If you're considering HDPE for your next project or are interested in learning more about our high-quality HDPE boards and sheets, we're here to help. With over 20 years of experience in producing and selling insulating sheets and a decade of expertise in international trade, we're well-equipped to provide you with the perfect solution for your needs. For more information about our HDPE products or to discuss your specific requirements, please don't hesitate to contact us at info@jhd-material.com.

References

1. Peacock, A. J. (2000). Handbook of polyethylene: structures, properties, and applications. CRC Press.

2. Vasile, C., & Pascu, M. (2005). Practical guide to polyethylene. iSmithers Rapra Publishing.

3. Shenoy, A. V., & Saini, D. R. (1996). Thermoplastic melt rheology and processing. CRC Press.

4. Brydson, J. A. (1999). Plastics materials. Elsevier.

5. Crawford, R. J., & Throne, J. L. (2001). Rotational molding technology. William Andrew.

6. Andrady, A. L. (2003). Plastics and the Environment. John Wiley & Sons.

拷贝.webp)