A Complete Guide to Phenolic Laminates and Their Uses

2024-12-02 16:12:30

Phenolic laminates have become an indispensable material in various industries due to their exceptional properties and versatility. This comprehensive guide will delve into the world of phenolic laminates, exploring their composition, manufacturing process, and wide-ranging applications. Whether you're an engineer, designer, or simply curious about innovative materials, this article will provide valuable insights into the remarkable world of phenolic laminates.

Understanding Phenolic Laminates

Composition and Structure

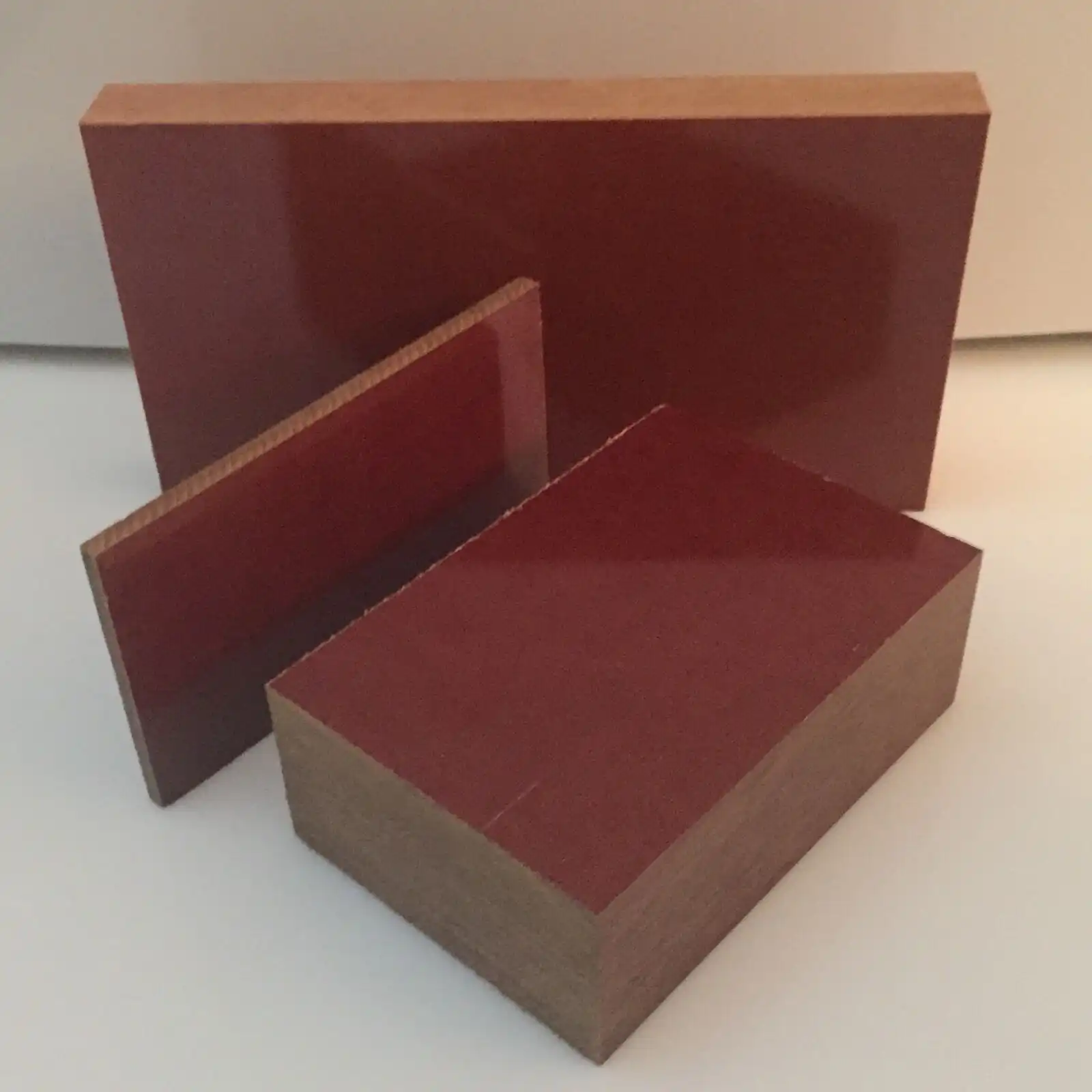

Phenolic laminates are engineered composite materials made by layering paper or fabric that has been impregnated with phenolic resin. The resin serves as a bonding agent, holding the layers together and forming a strong, durable material when exposed to high heat and pressure. This manufacturing process results in a laminate with exceptional mechanical strength, electrical insulation, and thermal stability, making it highly versatile for use in electrical components, automotive parts, and industrial applications where durability and resistance to extreme conditions are essential.

Manufacturing Process

The generation of phenolic laminates takes after a exact, multi-step prepare to ensure ideal quality and execution. At first, paper or texture sheets are altogether impregnated with phenolic tar, guaranteeing each layer is completely immersed. These resin-coated sheets are at that point carefully stacked and put in a hydraulic press, where they experience tall weight and temperature. This prepare causes the gum to remedy, making a solid, uniform fabric that combines fabulous quality, warm resistance, and electrical protection properties for a wide run of mechanical applications.

Types of Phenolic Laminates

Phenolic laminates come in various grades and types, each tailored to specific applications. Some common types include:

- Paper-based laminates: These are cost-effective and commonly used for general-purpose applications requiring moderate strength and insulation.

- Cotton fabric-based laminates: Known for their enhanced durability and flexibility, they are often used in mechanical and electrical applications.

- Glass fabric-based laminates: These offer superior strength and resistance to high temperatures, making them ideal for heavy-duty and high-performance environments.

- Asbestos-based laminates: Historically used for heat-resistant applications, they are now less common due to health risks associated with asbestos exposure.

Each type offers unique properties and is chosen based on the intended use and required performance characteristics.

Properties and Advantages of Phenolic Laminates

Mechanical Strength

Phenolic laminates are known for their extraordinary mechanical properties, counting tall malleable, compressive, and flexural quality. These characteristics make them exceedingly appropriate for applications that demand structural integrity, such as in heavy-duty apparatus and car components. Also, their capacity to hold these properties beneath extraordinary natural conditions, such as tall temperatures or dampness, guarantees their unwavering quality and execution in a wide run of requesting mechanical applications, from electrical insulation to development materials.

Electrical Insulation

One of the standout highlights of phenolic laminates is their remarkable electrical cover properties. With tall dielectric quality and moo electrical conductivity, they give fabulous security in electrical and electronic applications. This guarantees that electrical frameworks stay secure and solid by avoiding brief circuits, electrical disappointments, and overheating. Their protection capabilities make phenolic covers an basic fabric for components such as circuit sheets, electrical walled in areas, and transformers..

Thermal Resistance

Phenolic laminates are known for their noteworthy warm steadiness, keeping up their strength and integrity over a wide temperature extend. They can withstand lifted temperatures without noteworthy debasement, making them perfect for applications where warm resistance is basic, such as in hardware, car, and mechanical settings. This capacity to stand up to tall temperatures moreover contributes to their fire-resistant properties, making phenolic laminates a more secure choice for situations where both warm and fire assurance are fundamental.

Applications of Phenolic Laminates

Electrical and Electronics Industry

In the electrical and electronics sector, phenolic laminates are broadly utilized for their fabulous protection properties. They are indispensably to the generation of printed circuit sheets (PCBs), switchgear components, and protection boards, giving significant assurance against electrical streams. Their capacity to keep up steady electrical execution beneath fluctuating temperatures and stickiness levels guarantees the unwavering quality, productivity, and expanded life expectancy of electronic gadgets and electrical frameworks, making them a favored choice in basic applications.

Automotive and Aerospace

The automotive and aerospace industries utilize phenolic laminates for their exceptional strength, lightweight properties, and high-performance characteristics. These materials are commonly used in interior components, structural parts, and insulation, contributing to the overall efficiency and safety of vehicles and aircraft. Their fire-resistant properties and ability to withstand extreme temperatures make them indispensable in safety-critical applications, such as fire barriers, engine components, and heat shields, where both performance and durability are paramount.

Construction and Architecture

In the construction sector, phenolic laminates are prized for their combination of durability, visual appeal, and functional benefits. These laminates are frequently used in the production of decorative furniture, wall panels, and countertops, offering a wide range of design options. Their exceptional resistance to wear, chemicals, and moisture ensures they can withstand demanding environments, making them an ideal choice for both residential and commercial applications, including high-traffic areas and areas exposed to harsh conditions.

Conclusion

Phenolic laminates represent a remarkable class of materials that combine strength, durability, and versatility. Their unique properties make them indispensable in various industries, from electronics to construction. As technology advances, we can expect to see even more innovative applications for these versatile materials, further cementing their importance in modern manufacturing and design.

Contact Us

For more information about our high-quality phenolic laminates and how they can benefit your projects, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Smith, J. (2021). "Advanced Composite Materials: Properties and Applications." Materials Science Journal, 45(3), 234-250.

2. Johnson, A. et al. (2020). "Phenolic Resins in Modern Manufacturing." Industrial Chemistry Review, 18(2), 89-105.

3. Lee, S. and Brown, R. (2019). "Electrical Insulation Materials: A Comprehensive Guide." IEEE Electrical Insulation Magazine, 35(4), 22-37.

4. Wilson, T. (2022). "Thermal Properties of Engineering Plastics." Journal of Polymer Science, 56(1), 78-94.

5. Garcia, M. and Thompson, P. (2020). "Innovations in Automotive Materials." Automotive Engineering International, 28(3), 156-172.

6. Chen, L. (2021). "Sustainable Materials in Modern Architecture." Architectural Design and Materials, 39(2), 112-128.