Epoxy Resin For Crafts

Basic Information:

Brand:Jinghong

Material:Epoxy Resin

Color: Transparent

Shelf Life:12 Months

Model Number: JQ-12 JQ-21 JQ-31

Payment Terms: L/C T/T Credit Card

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Production Description

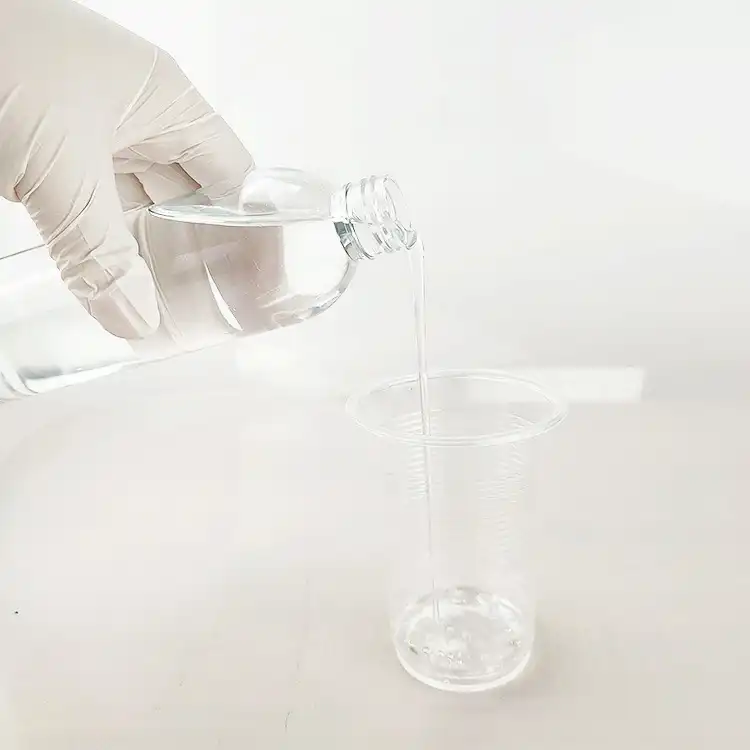

Epoxy Resin for Crafts can be cured under normal temperature and high temperature, with the feature of good flowing property, natural defoaming, anti-yellow, high transparency, no ripple, bright in surface.It can be widely used for drops of glue, signs, cards, crafts, lighting, photo frame, lamp potting and mold filling, etc..

There are three types of epoxy resin:

| Types | Weight Ratio | Viscosity of A | Viscosity of B | Operation Time | Final Curing Time | Initial Curing Time | ShoreD |

JQ-12 | 1:1 | 2000cps | 1300cps | 30min | 24h | 3h | 80±3D |

| JQ-21 | 2:1 | 2000cps | 80cps | 1h | 48h | 8h | 80±5D |

| JQ-31 | 3:1 | 800cps | 50cps | 40min | 24h | 4h | 83±3D |

Feature

Epoxy Resin for Crafts is high transparency, self defoaming, yellowing resistance and easy to operate. It can be cured at normal temperature or by heating. Also clear, low viscosity, nature defoaming, super transparency and can get any color you want by add piments. No ripple,bright in surface,odourless,eco-friendly,nontoxic,waterproof and so on.

Technology Data

Part | JQ-12A | JQ-12B |

Color | Transparent | Transparent |

Specific gravity | 1 | 1 |

Viscosity (25℃) | 4000-8000CPS | 50 MAXCPS |

Mixing ratio | A: B = 100:33(weight ratio) | |

Hardening conditions | 25 ℃×8H to 10H or 55℃×1.5H (2 g) | |

Usable time | 25℃×40min (100g) | |

Part | JQ-21A | JQ-21B |

Color | Transparent | Transparent |

Specific gravity | 1.15 | 1.15 |

Viscosity (25℃) | 800-2000CPS | 100 MaxCPS |

Mixing ratio | A: B = 100:50(weight ratio) | |

Hardening conditions | 25℃×7H or 80℃×2H(2g) | |

Usable time | 25℃×40min(100g) | |

Part | JQ-31A | JQ-31B |

Color | Transparent | Transparent |

Specific gravity | 1.15 | 0.97 |

Viscosity (25℃) | 2000-4000CPS | 50 MAXCPS |

Mixing ratio | A: B = 100:33(weight ratio) | |

Hardening conditions | 25 ℃×24H (100 g) | |

Usable time | 25℃×60min (100g) | |

Operation

1.Weigh A and B glue according to the given weight ratio into the prepared cleaned container, fully mixed the mixture again the container wall by clockwise, place it along for 3 to 5 minutes, and then it can be used.

2.Take the glue according to the usable time and dosage of mixture to avoid wasting. When the temperature is below 15 ℃, please heat A glue to 30 ℃ first and then mix it to the B glue (A glue will be thicken in low temperature ); The glue must be sealed lid after use to avoid rejection caused by moisture absorption.

3.When the relative humidity is higher than 85%, the surface of the cured mixture will absorb moisture in the air, and form a layer of white mist in the surface, so when the relative humidity is higher than 85%, is not suitable for room temperature curing, suggest to use the heat curing.

Caution

1,The operating environment should be ventilate and should keep away from fire. Closely sealed after use.

2, Avoid eye contact, in case of contact, wash with plenty of water and get medical attention immediately.

3, If contact skin, wrap with clean cloth or paper, and wash it with water and soap.

4, Keep away from children.

5, Please take a trial before application to avoid usage mistake.

Factory Equipment

Hebei Linyuan Fine Chemical Co., Ltd. was established in January 2017, and it was funded and constructed by Hebei JingHong Electronic Technology Co., Ltd and its subsidiary Hongda Insulation Material Factory which specialize in the production of 3240 Epoxy Resin Board, FR4 Fiberglass Sheet, Phenolic Cotton Cloth Laminate Sheet 3026, phenolic paper board and copper clad laminate.

JingHong had a factory before in Xiong'an New District, Hebei, which produced E44 epoxy resin only. The production volume was small and part of it was used for its own. Therefore, there was not much sales in the market. Due to the wide applications of epoxy resin, China has become the world's largest producer and consumer of epoxy resins. In order to comply with the market trend, the company combined the company's own situation, withdrew from Xiong'an New Area, and built an epoxy wholesale prices factory with an annual output of 20,000 tons in Cangzhou. The project has been completed and put into production.

The project is designed with reference of Japan’s Toto Kasei technology. The current production of epoxy wholesale prices include E44, E51, etc., and varieties will be gradually added according to market demand in the future. The person who take in charge of the company said: At present, the epoxy resin production capacity is 20,000 tons. According to the actual market situation, the production capacity is going to expand to 100,000 tons.

Storage And Shelf Life

1, Store at the temperature of 25°C or cool and dry place. Avoid from sunlight, high temperature or high humidity environment.

2, Use up as soon as possible when opened. It is strictly forbidden to expose to the air for a long time after it is opened to avoid affecting the quality of the products. The shelf life is six months in the room temperature of 25°C degree.

Packaging and Shipping

Send Inquiry