Can FR4 Epoxy Sheets be used in outdoor applications?

2024-06-06 16:32:29

Can FR4 Epoxy Sheets be used in Outdoor Applications?

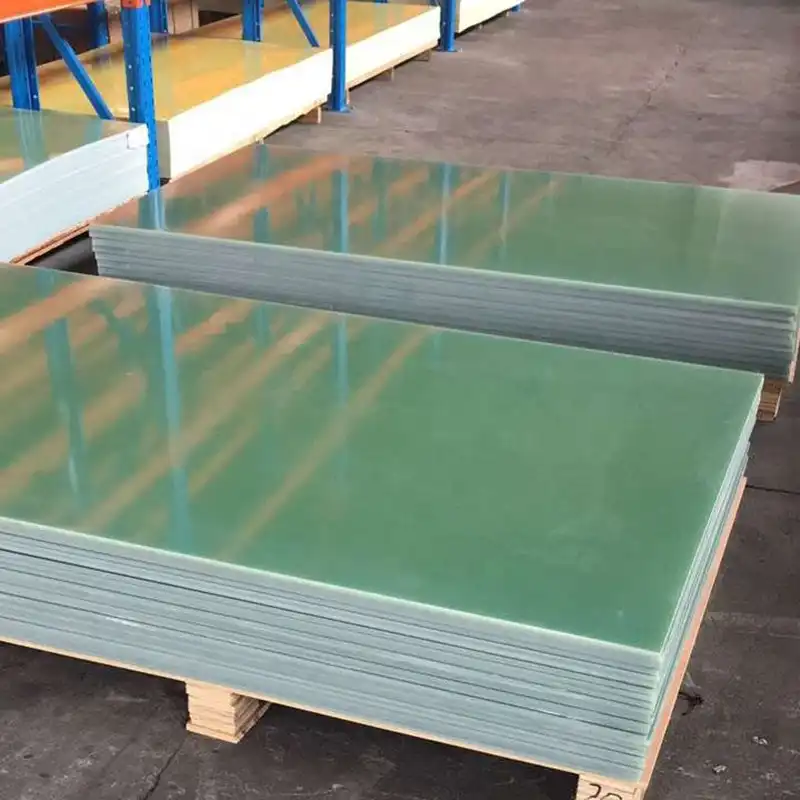

Epoxy Resin Sheets are eminent for their outstanding mechanical heartiness and great electrical protection properties, pursuing them a favored decision for different modern applications. Containing woven fiberglass material impregnated with epoxy tar, these sheets are designed to convey unmatched solidness and unwavering quality in requesting conditions. Their intrinsic fire resistant qualities further improve their reasonableness for applications where fire wellbeing is a fundamental concern.

Notwithstanding their broad usage in a different scope of settings, the sending of FR4 epoxy sheets in outside conditions requires cautious thought of a few key variables. The remarkable difficulties presented by open air conditions, like openness to UV radiation, dampness, temperature varieties, and mechanical pressure, can influence the presentation and life span of these materials. UV radiation, specifically, can debase the epoxy tar grid over the long haul, possibly compromising the underlying honesty and electrical properties of the sheets.

Understanding FR4 Epoxy Sheets

FR4 Epoxy Sheet are profoundly esteemed for their excellent sturdiness and predominant electrical protection properties, delivering them appropriate for a different range of utilizations. Their vigorous piece, contained a woven fiberglass fabric and epoxy gum, saturates them with the strength and versatility essential for use in requesting conditions. These sheets are generally utilized in electronic applications, where their phenomenal protecting qualities add to the dependable exhibition of electronic parts and circuits. Moreover, FR4 sheets are as often as possible used as primary parts because of their ability to offer mechanical help and steadiness inside different frameworks and gear.

Suitability of FR4 Epoxy Sheets for Outdoor Use

The usage of FR4 sheets in outside settings requires an exhaustive assessment of the particular natural circumstances to which they will be uncovered, as their presentation and life span can be fundamentally impacted by outer elements. In spite of the fact that FR4 sheets offer a huge number of profitable properties, including uncommon strength and electrical protection capacities, their reasonableness for outside applications is dependent upon the predominant ecological boundaries.

FR4 material is ordinarily intended to endure temperatures inside a scope of - 40°C to 130°C, exhibiting its strength to a wide range of warm circumstances. Inside this temperature range, Epoxy Resin Sheets keep up with their mechanical strength and electrical properties successfully, guaranteeing solid execution in different settings. Nonetheless, openness to temperatures past this predefined reach can set off corruption in the material, possibly undermining its underlying uprightness and protecting qualities.

To alleviate the gamble of disintegration under outrageous temperatures, proactive measures, for example, consolidating extra intensity safe coatings or carrying out warm administration methodologies might be vital while sending FR4 sheets in open air conditions described by temperature vacillations. Via cautiously surveying the warm circumstances and executing proper protections, the innate qualities of FR4 material can be enhanced for open air applications, empowering supported execution and life span while maintaining the material's legitimate traits of sturdiness and electrical protection.

Challenges with Outdoor Use

While considering the use of FR4 sheets in outside conditions, it is essential to perceive an outstanding constraint related with their exhibition under unambiguous natural stressors, especially delayed UV openness and outrageous weather patterns. While FR4 sheets display uncommon mechanical strength and electrical protection properties inside controlled indoor settings, their flexibility to outside components requires intensive thought.

Delayed openness to bright (UV) radiation represents a critical test for FR4 sheets, as the epoxy fastener inside the material can go through corruption when exposed to extreme daylight. This debasement cycle can possibly decrease the mechanical strength of the material, thus risking its underlying uprightness and unwavering quality in open air applications. Moreover, the breakdown of the epoxy folio under UV openness might build the weakness of FR4 sheets to delamination or breaking, further undermining their presentation and life span.

Protective Measures for Outdoor Use

While considering the use of FR4 Epoxy Sheet in open air conditions, it is basic to recognize the need of carrying out proactive defensive measures to protect the material from the adverse impacts of delayed openness to daylight and brutal weather patterns. Given the innate weakness of FR4 sheets to UV radiation and outrageous ecological stressors, the reception of defensive techniques, like the use of UV-safe coatings or the utilization of nooks, arises as a basic thought to guarantee the supported exhibition and life span of the material in outside settings.

The sending of UV-safe coatings addresses a compelling defensive measure pointed toward protecting FR4 sheets from direct daylight. These particular coatings are intended to alleviate the debasement cycle prompted by UV radiation, subsequently safeguarding the mechanical strength and underlying honesty of the material overstretched times of outside openness. By framing a strong hindrance against UV beams, these coatings act as an imperative protection instrument, permitting FR4 sheets to keep up with their fundamental properties and usefulness regardless of the imposing difficulties presented by daylight.

Alternatives for Better Outdoor Performance

While tending to applications that request raised UV solidness and strength to shifting weather patterns, it becomes fundamental to consider materials expressly designed for outside use, as they can give better execution thought about than standard FR4 sheets. In particular, UV-balanced out polycarbonate and select grades of acrylic arise as additional reasonable choices for such requesting applications because of their intrinsic ability to endure direct daylight and different atmospheric conditions, in this manner guaranteeing delayed life span and steady execution. UV-balanced out polycarbonate stands apart as a great decision for open air applications requiring high UV steadiness.

Conclusion

In summary, while Epoxy Resin Sheets can be used outdoors, they require appropriate protective measures to ensure their durability and effectiveness. Careful consideration of the environmental conditions and potential protective strategies is crucial for the successful use of FR4 sheets in outdoor applications. For projects that demand high UV and weather resistance, exploring alternative materials is recommended.

For more detailed information or specific queries regarding the use of FR4 epoxy sheets in outdoor applications, feel free to reach out to our team at info@jhd-material.com. As a professional manufacturing supplier with a large inventory, complete certifications, and extensive support capabilities including OEM and fast delivery, we are equipped to meet your needs and ensure the best material selection for your projects.