How do you cut a Flame Resistance FR4 Fiber Glass Laminate Sheet?

2024-06-07 16:31:03

1. Understanding FR4 Fiber Glass Laminate Sheets

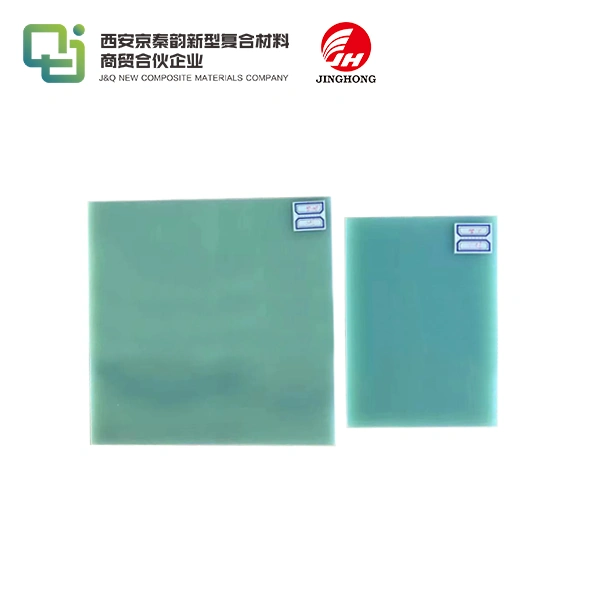

To properly cut a Flame Resistance (FR) FR4 Fiber Glass Laminate Sheet, it’s crucial to understand what it is. Flame Resistance FR4 Fiber Glass Laminate Sheet is a type of composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant. It is widely used in electronics, such as printed circuit boards (PCBs), due to its excellent electrical insulation properties, high mechanical strength, and resistance to heat and chemicals. The "FR" designation indicates that it has flame-retardant properties, making it suitable for applications where safety is paramount.

2. Safety Precautions Before Cutting

Some time recently endeavoring to cut an FR4 Fiber Glass Cover Sheet, it's basic to take appropriate security safeguards. This fabric can create fine fiberglass clean when cut, which can bother the skin, eyes, and respiratory framework if breathed in. In this manner, it is vital to wear suitable individual defensive hardware (PPE), counting security glasses, a tidy veil, and gloves, to minimize presentation. Furthermore, guarantee that the cutting range is well-ventilated to decrease the concentration of airborne particles.

Another critical security degree is to utilize the fitting cutting apparatuses and methods for FR4 fiber glass cover sheets. These materials are more unbending than standard plastics and require sharp, solid cutting apparatuses to avoid splitting or uneven edges. A accuracy saw or a diamond-coated cutting edge ought to be utilized for clean, exact cuts. It's moreover fitting to secure the FR4 sheet in put to avoid it from moving amid the cutting prepare, which can lead to mischances or wrong cuts.

Furthermore, after cutting, it's basic to appropriately clean the work range to expel any fiberglass tidy and flotsam and jetsam. Utilize a vacuum cleaner with a HEPA channel to capture fine particles viably, and arrange of the collected tidy agreeing to nearby directions for dangerous squander. Cleaning the work zone not as it were keeps up a secure environment but moreover makes a difference secure the execution of your hardware by anticipating the aggregation of rough particles.

In outline, taking legitimate security safety measures some time recently cutting an FR4 fiber glass cover sheet is basic to ensure laborers from potential wellbeing dangers and guarantee a clean, exact cut. By taking after these rules, you can minimize the dangers related with dealing with this fabric and contribute to a more secure work environment.

3. Tools and Equipment Needed

Cutting an Flame Resistance FR4 Fiber Glass Laminate Sheet requires specific tools and equipment to achieve clean and precise results. Some of the essential tools include:

· Utility Knife: A sharp utility knife equipped with a carbide or diamond-coated blade is commonly used to score and cut FR4 sheets.

· Straightedge: A sturdy metal or plastic straightedge is used as a guide to ensure straight cuts.

· Cutting Surface: A stable cutting surface, such as a self-healing cutting mat or a piece of plywood, helps protect the underlying work surface and ensures clean cuts.

· Safety Gear: As mentioned earlier, safety glasses, a dust mask, and gloves are necessary to protect against fiberglass dust and debris.

4. Cutting Techniques

There are a few methods for cutting Flame Resistance FR4 Fiber Glass Laminate Sheet, depending on the craved accuracy and complexity of the cuts. Here are a few common methods:

·Scoring and Snapping: This strategy includes scoring the surface of the FR4 sheet numerous times with a utility cut, at that point snapping it along the scored line by twisting it over the edge of a table or utilizing a straightedge as leverage.

·Straight Cutting: For straight cuts, utilize a sharp utility cut and a straightedge to direct the edge along the craved cutting line. Apply firm, indeed weight to guarantee a clean cut without fraying or chipping.

·Circular Saw: A circular saw prepared with a fine-toothed carbide edge can be utilized for cutting bigger FR4 sheets or making bended cuts. Guarantee that the saw edge is reasonable for cutting fiberglass and alter the cutting speed and profundity accordingly.

·Water Fly Cutting: For complicated shapes and high-precision cuts, water fly cutting is a practical choice. This strategy employments a high-pressure stream of water blended with rough particles to cut through the FR4 fabric without creating warm or dust.

5. Wrapping up and Cleanup

After cutting the FR4 Fiber Glass Cover Sheet, it's fundamental to review the edges for any harshness or spiked edges. Utilize a fine-grit sandpaper or a deburring instrument to smooth out any blemishes and guarantee a clean wrap up. Also, altogether clean the cutting zone and arrange of any fiberglass tidy and flotsam and jetsam legitimately to avoid defilement and potential wellbeing risks.

Contact us for all your Flame Resistance FR4 Fiber Glass Laminate Sheet needs. We are a professional manufacturing supplier with a GMP factory, large inventory, and complete certificates. We support OEM orders and offer fast delivery with tight packaging to ensure product quality and customer satisfaction. For inquiries, contact us at info@jhd-material.com.

References:

1. "FR-4." Wikipedia, Wikimedia Foundation, 5 May 2024, en.wikipedia.org/wiki/FR-4.

2. "Safety Data Sheet - FR-4 Laminate and Prepreg." Isola Group, 2023, www.isola-group.com/wp-content/uploads/2020/03/IS200_FR406-N.pdf.

3. "Fiberglass Cutting Safety." Tap Plastics, www.tapplastics.com/product_info/about_plastics/fiberglass_cutting_safety.

4. "Safety Precautions for Working with FR4 PCBs." Screaming Circuits, 24 Mar. 2017, blog.screamingcircuits.com/2017/03/safety-precautions-for-working-with-fr4-pcbs.html.

5. "How to Cut Fiberglass." Family Handyman, www.familyhandyman.com/project/how-to-cut-fiberglass/.