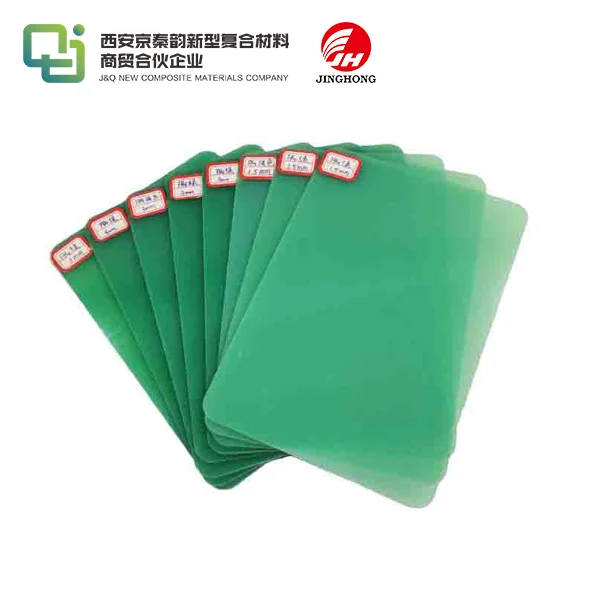

Insulation Epoxy Fiber Glass Laminated Sheet FR4

Basic Information:

Brand: Hongda

Materials: Epoxy Resin

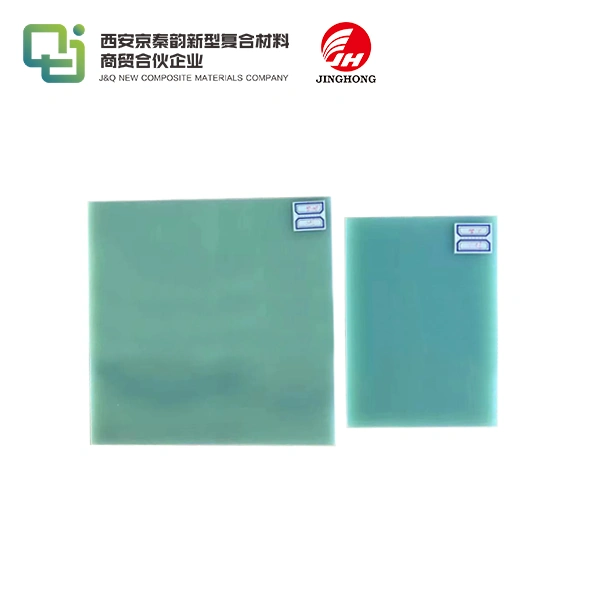

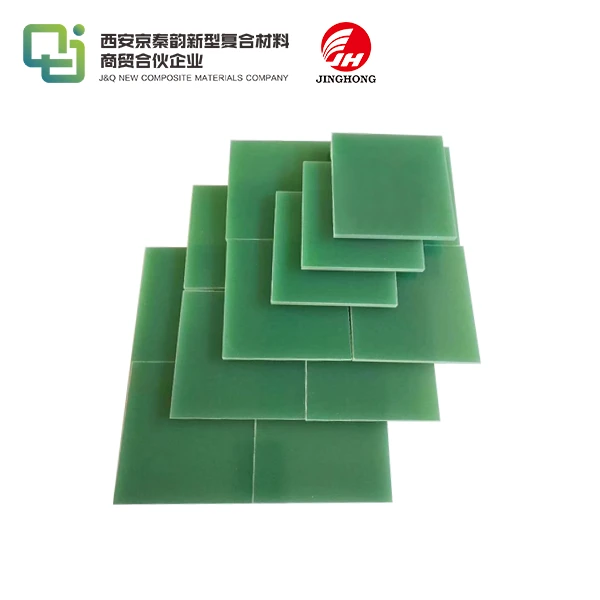

Nature Color: Light Green

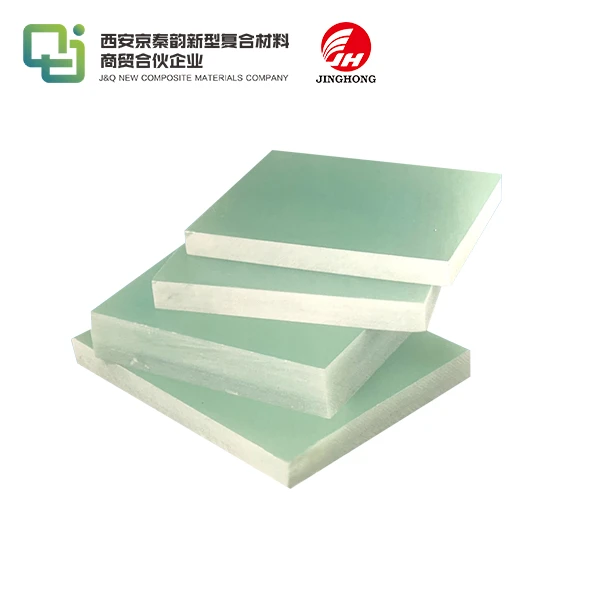

Thickness: 0.3mm --- 100mm

Regular Size: 1030mm*1230mm

Custom Size: 1030mm*2030mm, 1220mm*2440mm, 1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 13000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Production Description

Insulation Epoxy Fiber Glass Laminated Sheet FR4 is made by pure epoxy resin as glue with electric fiberglass cloth under high pressure and temperature. It has very high temperature resistance which is about 150 degrees centigrade, also the machinability and the electrical properties are excellent. FR4 has a UL flammability rating of 94 V0.

Application

FR4 Laminate Sheet can be used in electrical equipment, Antenna Insulators, Antenna bases, Test Boards, End Plates, Terminal Boards, Circuit Board Holders, Underwater Conditions. It is also very suitable for copper clad laminated and printed circuit board.

Technical Data for FR4

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-0 |

GB/T 2408-2008 |

|

REMARK: 1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

|

|

|

|

| New Energy Vehicle Industry | Mould in Cloth and Shoes | Capacitor Industry |

It can be machined to various shapes as insulation parts in which the mechanical and electrical properties is required.

Factory

|

|

|

| two environmental control equipment used for the cyclic utilization of exhaust gas incineration afterheat | six domestically most advanced gum-dipping drying production equipment |

Packaging and Shipping

Regular packing, Protect by Pallet

Send Inquiry