UV Epoxy Resin

Basic Information:

Brand:Jinghong

Material:Epoxy Resin

Color: Transparent

Shelf Life:12 Months

Model Number: JQ-UV

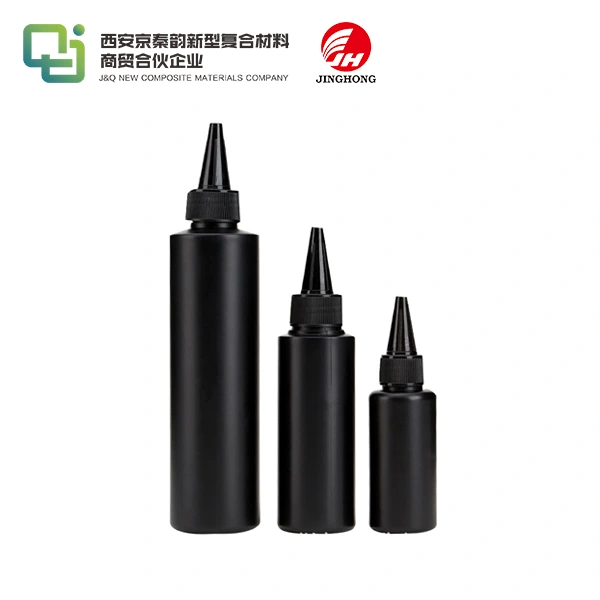

Specification: 20g,50g,100g,200g,250g,1000g

Payment Terms: L/C T/T Credit Card

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Production Description

UV Epoxy Resin, also known as ultraviolet resin, is a type of resin that cures and hardens when exposed to ultraviolet light. It's commonly used in crafts, jewelry making, and prototyping due to its fast curing time and clear, glossy finish.

UV Epoxy Resin is popular for its quick curing time, typically within minutes, which allows for rapid production and completion of projects. Additionally, it can be used to encapsulate objects, create coatings, or build up layers for 3D effects. Its versatility makes it a favored material among crafters and artisans.

Single part clear Acrylic resin Cured hard Coveninent to use, easy to defaoming within minutes under UV or direct sunlight High transparency and low shrinking Non-yellowing Environmentally friendly non- toxic.

HIGHER QUALITY:

Undoubtedly excellent transparency, 100% crystal clear and non-yellowing, with hard glassy finish and uniform

gloss. Less shrinking, less bubbles, lower viscosity.

EASIER TO USE:

No preparation is required for UV epoxy resin. Specially designed nozzle make it easy to control your drops.Perfectly suited for resin jewelry making and crafts decorations, resin pour art, paint, garment accessories and other DIY crafts.

Data Sheet

|

Model No. |

Viscosity |

Hardness (shore D) |

Hardening Conditing UV-LED(24W) |

|

JQ11-UV |

1000-1500cps |

83D |

Each side 120s |

|

JQ12-UV |

3500-5000cps |

86D |

Each side 180s |

|

Application: Various DIY mold creative, Object Bonding Repair, Potting of small electronic components etc. |

|||

Instructions :

Directly pour the resin in the mold or the bezel.

Add the pigment, glitter, dried flowers or anything you want in it using a toothpick or tweezers, and cure the resin with UV light.

Gradually add the amount of the pigment to adjust the color instead of pouring too much pigment at a time.

How to avoid bubbles?

UV epoxy resin should be poured in silicone molds in layers, allowing air bubbles completely escape.

To expedite the process of escaping of bubbles and time of solidification of resin, the mold can be a bit warmed up.

Forexample, heat the oven to 80℃(176℉), turn off, ventilate it a little and filled the mold with the resin.

Before using the resin, place it upside down to prevent air bubbles from escaping during extrusion.

Use a toothpick to concentrate the air bubbles on the surface of the resin. Puncture them with a pin or undo them by applying heat with a heat gun or a lighter.

Operation

1. Prepare the materials.

2. Slowly inject UV epoxy resin into the mold.

3. Illuminate both sides for 1-2 minutes each.

4. Remove the finished product after cooling.

Factory Equipment

Hebei Linyuan Fine Chemical Co., Ltd. was established in January 2017, and it was funded and constructed by Hebei JingHong Electronic Technology Co., Ltd and its subsidiary Hongda Insulation Material Factory which specialize in the production of 3240 Epoxy Resin Board, FR4 Fiberglass Sheet, Phenolic Cotton Cloth Laminate Sheet 3026, phenolic paper board and copper clad laminate.

JingHong had a factory before in Xiong'an New District, Hebei, which produced E44 epoxy resin only. The production volume was small and part of it was used for its own. Therefore, there was not much sales in the market. Due to the wide applications of epoxy resin, China has become the world's largest producer and consumer of epoxy resins. In order to comply with the market trend, the company combined the company's own situation, withdrew from Xiong'an New Area, and built an epoxy resin factory with an annual output of 20,000 tons in Cangzhou. The project has been completed and put into production.

The project is designed with reference of Japan’s Toto Kasei technology. The current production of epoxy resins include E44, E51, etc., and varieties will be gradually added according to market demand in the future. The person who take in charge of the company said: At present, the epoxy resin production capacity is 20,000 tons. According to the actual market situation, the production capacity is going to expand to 100,000 tons.

Packaging and Shipping

Send Inquiry