What was a benefit of bakelite?

2024-11-22 17:06:49

Bakelite, the world's first synthetic plastic, was a game-changer in the early 20th century, transforming industries and everyday life alike. Its innovative properties, such as electrical insulation, heat resistance, and moldability, made it a versatile material for a wide range of uses, from consumer goods to industrial components. In this detailed exploration, we will examine Bakelite’s key advantages, how it influenced manufacturing practices, and its lasting legacy in modern design and material science, continuing to shape the development of plastics today.

The Versatility of Bakelite

Electrical Insulation Properties

One of Bakelite's most remarkable advantages was its superior electrical insulation properties, which revolutionized the electrical industry. This thermosetting plastic became the go-to material for crafting electrical components, switchboards, and insulating devices where safety was paramount. Its resistance to high temperatures and inability to conduct electricity ensured reliability and durability, even under demanding conditions. These qualities made Bakelite an indispensable choice for safeguarding electrical systems in homes, industries, and beyond.

Heat Resistance

Bakelite's exceptional heat resistance made it a standout material in its era, capable of withstanding high temperatures without warping or degrading. This durability allowed it to be widely used in applications such as cookware handles, automotive components, and industrial machinery. Its ability to retain structural integrity under thermal stress ensured that Bakelite products performed reliably, even in demanding environments, cementing its reputation as a versatile and robust material for both domestic and industrial use.

Chemical Resistance

Bakelite's strong resistance to chemicals was another key advantage that set it apart. It proved invaluable in laboratory settings, where it could endure exposure to acids, bases, and solvents without deteriorating. This resilience extended its utility to industrial applications, where contact with harsh chemicals was common. By maintaining its integrity and performance in such environments, Bakelite not only enhanced safety but also ensured longevity, making it a reliable choice for demanding chemical conditions.

The Impact on Manufacturing

Cost-Effective Production

The affordability of Bakelite's manufacturing process gave it a significant edge over traditional materials like wood and metal. Its low production costs enabled the large-scale creation of consumer goods, bringing everyday items within reach of a broader audience. Additionally, Bakelite could be easily molded into intricate shapes without the need for costly machining, streamlining production and further reducing expenses. This combination of versatility and cost-efficiency made Bakelite a driving force in democratizing modern products.

Durability and Longevity

Bakelite's remarkable durability made it a preferred material in manufacturing, offering superior resistance to wear, impacts, and environmental factors compared to many alternatives. Products crafted from Bakelite could endure decades of use, maintaining functionality and appearance even under challenging conditions. This longevity reduced the need for frequent replacements, making Bakelite a cost-effective and sustainable choice. Its ability to conserve resources by extending product life further underscored its value in both industrial and everyday applications.

Versatility in Design

Bakelite's exceptional moldability revolutionized product design by enabling the creation of complex shapes and detailed patterns that traditional materials could not achieve. This flexibility allowed manufacturers to produce items that were not only highly functional but also visually appealing, catering to both practical and aesthetic demands. From elegant consumer goods to specialized industrial components, Bakelite's versatility supported innovation across industries, transforming how products were designed and manufactured for a modern audience.

The Legacy of Bakelite

Influence on Modern Plastics

The invention of Bakelite marked a turning point in material science, laying the foundation for the development of countless synthetic plastics that followed. Its groundbreaking properties, such as durability, heat resistance, and moldability, set standards that continue to shape modern plastic design and production. The insights gained from Bakelite's applications have driven advancements in polymer chemistry, inspiring innovations that extend its legacy in industries ranging from consumer goods to high-tech engineering.

Collectibility and Historical Significance

Today, vintage Bakelite pieces are treasured by collectors, celebrated for their distinctive qualities and historical importance. These items, ranging from jewelry to household goods, reflect the innovative design and craftsmanship of the early 20th century. Their rarity and timeless appeal have made them valuable artifacts, symbolizing a transformative era in manufacturing. The enduring fascination with Bakelite highlights its cultural and technological impact, long after its prime in industrial and consumer applications.

Environmental Considerations

While Bakelite brought numerous advantages, its environmental impact warrants consideration. As a thermosetting plastic, it cannot be melted and recycled like many modern alternatives. However, its exceptional durability often translated into decades of use, minimizing the frequency of replacements and waste. This longevity offered a stark contrast to the disposable nature of many contemporary plastics, partially offsetting its environmental footprint. Bakelite’s legacy underscores the balance between innovation and sustainability in material design.

Conclusion

The advantages of Bakelite were revolutionary, encompassing exceptional electrical insulation, heat and chemical resistance, cost-efficiency, durability, and unmatched design flexibility. These qualities not only reshaped manufacturing but also profoundly influenced daily life throughout the 20th century, heralding the modern era of plastics. Although newer materials have largely replaced Bakelite in most applications, its contributions remain foundational. Its legacy continues to inspire advancements in material science and industrial design, highlighting its enduring impact on innovation and technology.

Contact Us

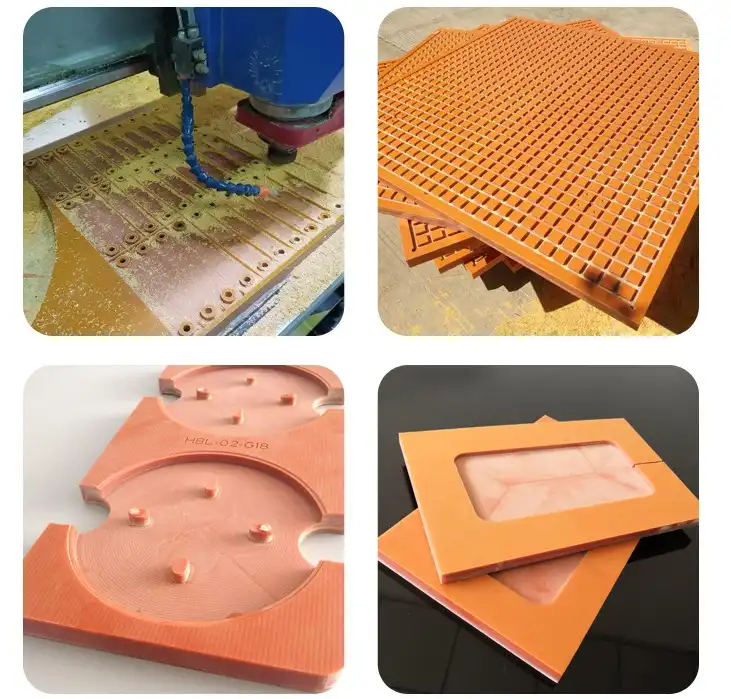

If you're interested in learning more about innovative materials for insulation and manufacturing, our company specializes in producing high-quality insulating sheets. With over 20 years of experience in production and 10 years in international trade, we offer expert knowledge and service. Contact us at info@jhd-material.com for more information on our products and how they can benefit your projects.

References

1. Kaufman, M. (1988). The First Century of Plastics: Celluloid and its Sequel. The Plastics and Rubber Institute.

2. Fenichell, S. (1996). Plastic: The Making of a Synthetic Century. HarperBusiness.

3. Meikle, J. L. (1995). American Plastic: A Cultural History. Rutgers University Press.

4. Reilly, J. M. (1991). Celluloid Objects: Their Chemistry and Preservation. Journal of the American Institute for Conservation, 30(2), 145-162.

5. Haring, K. (2007). Ham Radio's Technical Culture. MIT Press.

6. Friedel, R. (1983). Pioneer Plastic: The Making and Selling of Celluloid. University of Wisconsin Press.