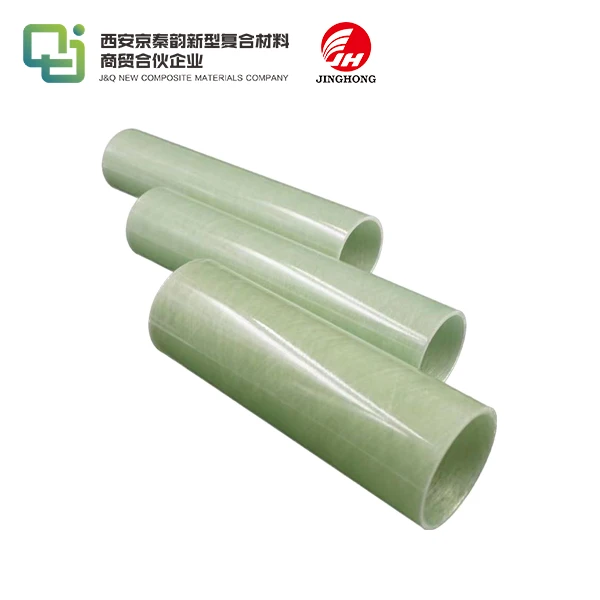

Low Temperature Fiberglass Reinforced Plastic

Materials: Epoxy Resin

Nature Color: yellow

Wall thickness: At least 0.5mm

Custom Size: Inner diameter φ5mm~φ1500mm

Outer diameter φ6mm~φ2000mm

The longest tube length is 2m

Packaging: Regular packing

Productivity: 100 tons per year

Transportation: Ocean, Land, Air

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

D3848 low temperature fiberglass reinforced plastic

low temperature fiberglass reinforced plastic is a special low-temperature insulation epoxy glass steel pipe material for -196℃. It is made of electrician's alkali-free glass fiber cloth impregnated with epoxy resin and baked by hot rolling.

Application

The mechanical strength is high, and the heat resistance grade is F grade, which is suitable for demanding low-temperature equipment, air separation equipment and tank trucks.

Instructions

1) The properties of laminated pipes are different from those of metal, so they should be processed according to JB/Z 141.

2) Due to the low thermal conductivity of the laminated tube, a small feed rate and high cutting speed should be used during machining.

3) After the laminated pipe is processed, it is easy to absorb moisture. It is best to dip-coated insulating paint for moisture-proof treatment.

4) Dust and odor are easily generated during mechanical processing of laminated pipes, so ventilation and dust removal and labor protection of workers should be strengthened.

5) It is best to use dry processing for laminated pipes, because the wet method (cooling with water) can easily change its dielectric properties and affect its use.

6) Store in the original package in a dry, cool, ventilated room or under a shed that is strictly forbidden to smoke or fire. The storage period is twelve months from the date of leaving the factory.

Technical Data

Table 1 (unit mm)

Allowable deviation of inner diameter | Wall thickness | Allowable deviation of wall thickness | TEST METHOD | ||

The smallest | The biggest | Wall thickness ≤10 | Wall thickness>10 | Q/DSJ-266 | |

±0.5 | 1.5 | 30 | ±0.5 | ±1.0 | |

Note: Wall thickness> 30mm is a non-standard specification, which can be produced through negotiation between the supplier and the buyer. | |||||

Table 2 (unit mm)

Nominal length | Allowable deviation |

420 | +25 |

820 | -5 |

950 | ±25 |

Table 3

Wall thickness/mm | Warpage(%) |

1.5~3.0 | ≤1 |

3.5~5.0 | ≤0.7 |

>5 | ≤0.5 |

Table 4

No | Performance | Unit | Require | TEST METHOD | ||

20℃ | -160℃ | |||||

1 | Density | g/cm3 | 1.65~1.80 | GB/T 5132 | ||

2 | Compressive strength | Layer direction | MPa | 210 | 280 | GB/T 1448 |

Vertical | 300 | 400 | ||||

3 | Tensile Strength | Layer direction | MPa | 25 | 35 | GB/T 1447 |

Vertical | 250 | 300 | ||||

4 | Impact toughness | Vertical | kJ/m2 | 25 | 35 | GB/T 1451 |

5 | Laminar shear strength | MPa | 30 | 40 | GB/T 1450.1 | |

6 | Thermal Conductivity | Layer direction | W/m·K | 0.46 | 0.36 | GB/T 1036 |

Vertical | 0.41 | 0.31 | ||||

7 | Linear expansion coefficient | Layer direction | 10-6/K | 23 | GB/T 3139 | |

Vertical | 55 | |||||

Remark: The surface of the product is smooth, without bubbles, wrinkles and cracks, without obvious scratches and signs of overheating. Slight wrinkles are allowed on the inner wall, and both ends are cut neatly. Slight cracks are allowed between the back-end surface layers of the glass steel pipe material with a wall thickness greater than 13mm. | ||||||

Z3848 low temperature fiberglass reinforced plastic

Epoxy fiberglass steel pipe is a special low-temperature insulation epoxy glass steel pipe material for -196℃. It is made of electrician's alkali-free glass fiber cloth impregnated with epoxy resin and baked by hot rolling.

Application

The mechanical strength is high, and the heat resistance grade is F grade, which is suitable for demanding low-temperature equipment, air separation equipment and tank trucks.

Instructions

1) The properties of laminated pipes are different from those of metal, so they should be processed according to JB/Z 141.

2) Due to the low thermal conductivity of the laminated tube, a small feed rate and high cutting speed should be used during machining.

3) After the laminated pipe is processed, it is easy to absorb moisture. It is best to dip-coated insulating paint for moisture-proof treatment.

4) Dust and odor are easily generated during mechanical processing of laminated pipes, so ventilation and dust removal and labor protection of workers should be strengthened.

5) It is best to use dry processing for laminated pipes, because the wet method (cooling with water) can easily change its dielectric properties and affect its use.

6) Store in the original package in a dry, cool, ventilated room or under a shed that is strictly forbidden to smoke or fire. The storage period is twelve months from the date of leaving the factory.

Technical Data

Table 1 (unit mm)

Allowable deviation of inner diameter | Wall thickness | Allowable deviation of wall thickness | TEST METHOD | ||

The smallest | The biggest | Wall thickness ≤10 | Wall thickness>10 | Q/DSJ-266 | |

±0.5 | 1.5 | 30 | ±0.5 | ±1.0 | |

Note: Wall thickness> 30mm is a non-standard specification, which can be produced through negotiation between the supplier and the buyer. | |||||

Table 2 (unit mm)

Nominal length | Allowable deviation |

420 | +25 |

820 | -5 |

950 | ±25 |

Table 3

Wall thickness/mm | Warpage(%) |

1.5~3.0 | ≤1 |

3.5~5.0 | ≤0.7 |

>5 | ≤0.5 |

Table 4

No | Performance | Unit | Require | TEST METHOD | ||

20℃ | -160℃ | |||||

1 | Density | g/cm3 | 1.65~1.80 | GB/T 5132 | ||

2 | Compressive strength | Layer direction | MPa | 180 | 250 | GB/T 1448 |

Vertical | 250 | 350 | ||||

3 | Tensile Strength | Layer direction | MPa | 20 | 25 | GB/T 1447 |

Vertical | 200 | 250 | ||||

4 | Impact toughness | Vertical | kJ/m2 | 20 | 35 | GB/T 1451 |

5 | Laminar shear strength | MPa | 25 | 35 | GB/T 1450.1 | |

6 | Thermal Conductivity | Layer direction | W/m·K | 0.45 | 0.35 | GB/T 1036 |

Vertical | 0.40 | 0.30 | ||||

7 | Linear expansion coefficient | Layer direction | 10-6/K | 26 | GB/T 3139 | |

Vertical | 65 | |||||

Remark: The surface of the product is smooth, without bubbles, wrinkles and cracks, without obvious scratches and signs of overheating. Slight wrinkles are allowed on the inner wall, and both ends are cut neatly. Slight cracks are allowed between the back-end surface layers of the glass steel pipe material with a wall thickness greater than 13mm. | ||||||

Special Note

The company strictly controls product quality in accordance with relevant product standards. Due to the diversity and variability of application conditions and many other factors, it does not rule out the need for users to conduct experiments on their own. Legally, certain properties of the product are not guaranteed to be fully applicable to a specific purpose, and the right to modify the information is reserved.

Picture of Factory

|  |

Send Inquiry