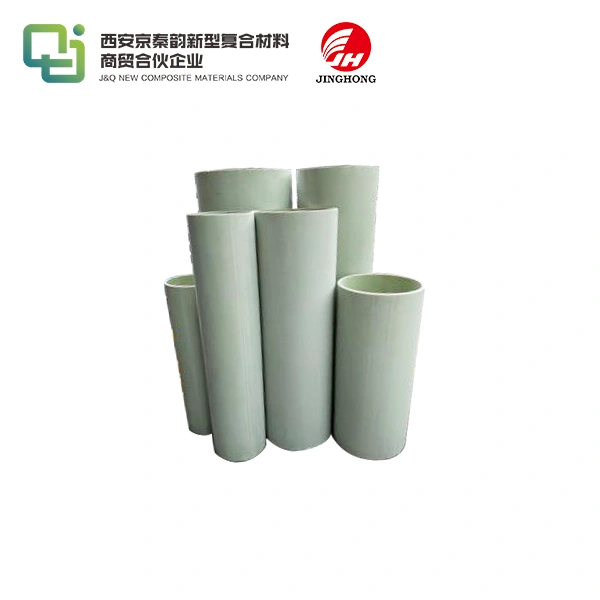

Epoxy Fiberglass Tube

Materials: Phenolic Resin

Nature Color: Green

Inner diameter φ8mm~φ550mm

Packaging: Regular packing

Productivity: 43000 tons per year

Transportation: Ocean, Land, Air

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Production Description

Epoxy fiberglass tube is made of electrician's alkali-free glass cloth soaked with epoxy phenolic resin by hot rolling and baking. It has high mechanical, thermal and dielectric properties. It is suitable for use as insulating structural parts in electrical equipment, and can be used in wet environment and transformer oil!

Appearance: the surface is smooth, free of blisters and blisters, and there are slight wrinkles and machining marks not exceeding the wall thickness tolerance.

Property

1. Various forms. Various resin, curing agent and modifier systems can almost meet the requirements of various applications, from very low viscosity to high melting point solids.

2. It is easy to cure. With different curing agents, the epoxy resin system can be cured in the temperature range of 0~180 ℃

3. Strong adhesion. The existence of inherent polar hydroxyl and ether bonds in the molecular chain of epoxy resin makes it have high adhesion to various substances.

4. Low shrinkage. The reaction between epoxy resin and curing agent is carried out by direct addition reaction or ring-opening polymerization of epoxy group in the resin molecule, without releasing water or other volatile by-products of epoxy pipe.

5. Mechanical properties. The cured epoxy resin system has excellent mechanical properties.

6. Electrical performance. The cured epoxy resin system is an epoxy resin with high dielectric properties and resistance to surface leakage.

7. Chemical stability. Generally, the cured epoxy resin system has excellent alkali resistance, acid resistance and solvent resistance.

8. Dimensional stability. The combination of many of the above properties makes the epoxy resin system have outstanding dimensional stability and durability.

9. Resistance to mold. The cured epoxy resin system is resistant to most molds and can be used in harsh tropical conditions.

Application

1. Cast insulation package for electrical appliances and motors. Such as electromagnet, contactor coil, transformer, dry-type transformer, etc. It has developed rapidly in the electrical industry. From normal pressure casting, vacuum casting to automatic pressure gel forming.

2. It is widely used for potting insulation of electronic components and circuit devices. It has become an indispensable and important insulating material in the electronic industry.

3. Electronic grade epoxy molding compound is used for plastic packaging of semiconductor components. It is developing very fast. Because of its superior performance, it has the tendency to replace traditional metal, ceramic and glass packaging.

4. Epoxy fiberglass tube are widely used in electronic and electrical fields. Among them, the development of epoxy copper clad laminate is particularly rapid and has become one of the basic materials of the electronic industry.

Technical Data for 3640

|

No |

Test Items |

Unit |

Requirement |

Test Result |

|

|

1 |

Density |

g/m3 |

≥1.65 |

1.70 |

|

|

2 |

Water Absorption |

MPa |

≤0.6 |

0.6 |

|

|

3 |

Thermal Stability (150℃/24h) |

/ |

|

No Crack and Bulge |

|

|

4 |

Vertical Layer Electrical Strength(90 ℃ in oil) |

MV/m |

|

8 |

|

|

5 |

Insulation Resistance |

Normal Condition |

Ω |

|

5.5*1012 |

|

2 Hours After Immersion |

1.9*104 |

||||

|

6 |

Volume Resistivity |

Ω·m |

/ |

2.4*1013 |

|

|

7 |

Dielectric Loss Factor |

/ |

/ |

8.1*103 |

|

Factory

J&Q Insulation Materials company is a foreign trade company controlled by Hebei JingHong Electronic Technology Co., Ltd., which is responsible for the export business of Hebei JingHong Electronic Technology Co., Ltd. The new factory of Hebei JingHong Electronics Co., Ltd. will be officially put into production in October 2022. Mainly produce FR4 sheet, 3240 epoxy sheet, Bakelite sheet, 3025 3026 phenolic cotton sheet, FR4 fiberglass tube, 3640 epoxy tube and 3520 phenolic paper tube. The total annual output of the new and old two factories reaches 43,000 tons, which will be the largest insulation board factory in China.

One of our greatest advantage is the orders which are directly from us has the priority to produce first. Also, we have our own logistics company, so it can provide safe and fast service to you. What we are trying to do is providing our customers one-stop service from production to delivery.

Our strength

1. The annual production capacity of the factory is 43,000 tons, which is one of the largest fiberglass tube manufacturers in China

2. Fully automated production workshop, product quality is stable

3. We have more than 20 years of experience in producing and selling insulating sheet, Cooperate with a number of domestic and foreign trading companies for many years.

4. Professional foreign trade team can provide perfect services

5. Have our own logistics company, provide one-stop service

Certification

Production Process

Exhibition

Package and Shipping

FAQ

Q: Are you trading company or manufacturer ?

A: We are fiberglass tube manufacturers.

Q:What about the package of product?

A:1. Wooden pallet with carton. 2. Plastic pallet with carton. 3. Wooden wooden pallet with wooden case. 4. According to customer requirements.

Q:What's the payment?

A: Payment<=1000USD, 100% in advance

Payment>=1000USD 30%TT advance, 70% TT before shipping

Q:If I need sample,what should I do?

A:It's our pleasure to send sample for you.You can send me your delivery address by email or message.We will send you . . . free sample at first time.

Q:Can you give me a discount price?

A:It is depending on the volume. The larger the volume is; the more discount you can enjoy.

Q:Why is your price a bit higher than other Chinese suppliers?

A:To meet the requirement of different customers and areas, our factory manufactures various kinds of quality for each . . . item at a wide range of price. We can offer the products of different quality levels depending on customer’s target price and quality requirement.

Q:How can you guarantee the quality of mass production is same with the sample sent to me before?

A:Our warehouse staff will leave another same sample in our company, with your company name marked on it, which our production will be based on.

Q:How can you deal with quality issues that customer feedback after receiving the goods?

A:1) Customers take photos of unqualified goods and then our sales staff will send them to Engineering Department to . verify.

2) If the issue is confirmed, our sales staff will explain the root cause and take corrective actions in coming orders.

3) Finally, we will negotiate with our customers to make some compensation.

Send Inquiry