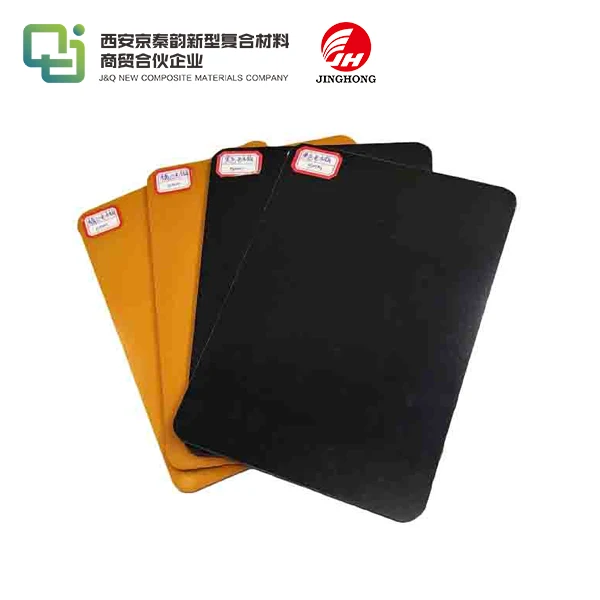

3021 Phenolic Paper Sheet

Basic Information:

Brand: JingHong

Materials: Phenolic Resin

Nature Color: Black and Orange

Thickness: 2mm --- 100mm

Regular Size: 1040mm*2080mm

Custom Size: 1220mm*2440mm

Packaging: Regular packing, Protect by Pallet

Productivity: 13000 Tons per year

Transportation: Ocean, Land, Air

Payment: T/T

MOQ: 500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Production Description

3021 Phenolic Paper Sheet — natural color is typically orange or black. known as Phenolic paper laminated owns the character of good mechanical strength, anti-static, intermediate electrical insulation. It`s made by insulating paper impregnated with phenolic resin, after baking hot pressing. This product is suitable for high performance requirements of electrical machinery, electrical equipment as insulating structural parts, and in the transformer oil.

3021 Phenolic Paper Sheet provides good electrical properties and is used in switchgear and transformers as switchboards, panel boards, and insulating washers and bushings.

It has lot of advantages:

-

easy to machine

-

the lowest cost of phenolics

-

phenolic paper laminate has good wear resistance

-

low moisture absorption

-

good mechanical strength

-

phenolic paper laminate is strong and stiff

-

high impact and compressive strength

Strengths

1. Excellent dielectric properties

2. Great machinability and easy to process

3. Superior resistance to acid, chemical solvents and insulating oil

Technical Data

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Water Absorption |

mg |

115 |

GB/T 1303.2-2009 |

|

2 |

Density |

g/cm3 |

1.33 |

|

|

3 |

Insulation Resistance after Soaking |

Ω |

2.1*108 |

|

|

4 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

2.7 |

|

|

5 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

KV |

11.8 |

|

|

6 |

Tensile Strength |

MPa |

119 |

|

|

7 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

3.99 |

|

|

8 |

Vertical Layer Modulus of Elasticity in Flexure (155℃ ± 2℃) |

MPa |

3.98*103 |

|

|

9 |

Bending Strength Perpendicular to Laminations |

MPa |

168 |

|

|

10 |

Adhesive Strength |

N |

3438 |

GB/T 1303.6-2009 |

|

REMARK: 1. NO.1 the sample size is (49.78~49.91) mm * (50.04~50.11) mm * (2.53~2.55) mm; 2. NO.4 the sample thickness is (2.12~2.15) mm; 3. NO.5 the sample size is (100.60~100.65) mm * (25.25~25.27) mm * (10.15~10.18) mm; 4. NO.10 the sample size is (25.25~25.58) mm * (25.23~25.27) mm * (10.02~10.04) mm; |

||||

Process Parts

|

|

|

|

| we can provide CNC machining service as your requirement, such as engraving and cutting. | ||

Production Process

|

Package and Shipping

Send Inquiry