Railway Drop Type Fuse Installation Related Standards

2023-03-22

1. Composition of high-voltage drop type fuse:

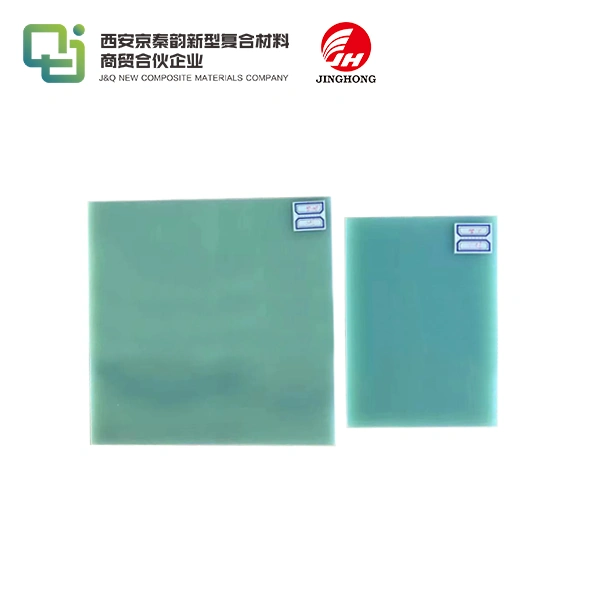

The high-voltage drop type fuse is composed of three parts: insulation support, dynamic and static contacts, and fuse tube. The static contacts are installed at both ends of the insulating support, and the fuse tube consists of an inner arc suppression tube and an outer layer of phenolic paper tube or epoxy glass fiber cloth tube.

2. High voltage drop type fuse Function and purpose:

Drop type fuses are applicable to power systems with a frequency of 50HZ and a rated voltage of 35KV and below, installed on the high voltage side of distribution transformers or on distribution trunk lines. The main functions include areas where protection performance is not required, which can be used in conjunction with isolation switches to replace automatic air switches; It can also be used in conjunction with load switches to replace expensive circuit breakers. It also has short circuit protection, overload, and isolation circuits.

3. Installation standards for drop type fuses:

a. The base (bracket) and all parts of the drop type fuse should be complete and firmly fixed, with the three-phase fulcrums on the same plane.

b. The horizontal distance between 10 KV drop type fuses should not be less than 500 mm.

c. The installation of drop type fuses shall meet the following requirements:

Ⅰ. The contact shaft shall be smooth and flexible, and the casting shall be free of cracks, sand holes, and rust.

Ⅱ. The inside of the fuse tube should be clean, and the fuse installation should be properly tightened and tightened.

Ⅲ. The fuse shall be installed firmly and arranged neatly, and the included angle between the axis of the fuse tube and the vertical line shall be 15 ° - 30 °. After the fuse is blown, the drop action should be flexible and reliable, with tight contact. The upper and lower leads should be tightly pressed, and the connection with the line conductor should be tight and reliable.

Ⅳ. The porcelain parts shall be in good condition, and the fusion tube shall be free of moisture absorption, expansion, or bending.

d. The specification of the fuse should meet the design requirements, and there should be no bending, flattening, or damage.

4. What should be maintained for drop type switches in operation?

a. Whether there are cracks, flashovers, and damages;

b. Whether there is movement up and down, left and right, and bolt looseness during operation;

c. Whether the duck's beak is too tight or loose;

d. Whether the contact between the duck beak and each part is good; The insulation resistance test shall be conducted once a year, and the unqualified ones shall be replaced.

5. Selection of fuse for high-voltage drop type fuses?

The drop type fuse is selected on the high-voltage side according to 2-3 times the rated current on the high-voltage side. The size of the transformer capacity determines the respective rated current levels on the high and low voltage sides, so the selection of fuse links is closely related to the transformer capacity.

The current can be calculated based on the voltage and transformer capacity, and the formula is as follows:

I=P/U √ 3, for example, the transformer capacity is 30KVA, the high-voltage side voltage is 10KV, and the current is:

I=30√10X1.732=30÷17.32=1.7A

The actual selection is 2-3 times 1.7A, which is 4-5A fuse.

For a transformer with a high voltage side of 10 KV, the current can be estimated by multiplying the capacity by 0.06, so 30X0.06=1.8 A, which is close to the above calculation.

_1740986340093.webp)