How is an FR4 Epoxy Sheet manufactured?

2024-06-04 13:46:54

How is an FR4 Epoxy Sheet Manufactured?

Introduction to FR4 Epoxy Sheets

Epoxy Resin Sheets are key materials widely used across assorted ventures, especially in gadgets for the manufacture of printed circuit sheets (PCBs). The assembling system includes impregnating woven fiberglass with epoxy tar, trailed by pressure under intensity and strain to yield strong sheets. This careful cycle guarantees that the fiberglass is totally soaked with epoxy sap, bringing about hearty and strong sheets famous for their remarkable electrical protection properties and mechanical strength.

In the domain of hardware, FR4 sheets are worshipped for their capacity to endure high temperatures, dampness, and synthetic openness, making them ideal substrates for PCBs. Their dielectric properties make them reasonable for working with the exact steering of electrical signs while offering underlying help to mounted parts. In addition, FR4 epoxy sheets show amazing layered dependability, guaranteeing that PCBs keep up with their respectability under different ecological circumstances.

Past hardware, FR4 sheets track down applications in aviation, car, and modern areas, where their strength to natural variables and mechanical stressors is profoundly esteemed. Their flexibility, unwavering quality, and cost-viability go with them a favored decision for a wide exhibit of uses, featuring their irreplaceable job across different ventures in empowering the headway of innovation and development.

Materials Used in FR4 Sheets

FR4 sheets, essential to various modern applications, contain woven fiberglass and an Epoxy Resin Sheets cover as their essential parts. These materials are every now and again increased with fire resistant added substances like bromine to stick to severe wellbeing norms. Prestigious for their remarkable mechanical strength, electrical protection properties, and fire retardancy, FR4 sheets are basic to different areas, including hardware, aviation, and car ventures.

The woven fiberglass grants underlying respectability and support to the sheets, making them impervious to actual effects and stresses. In the mean time, the epoxy sap cover gives bond and attachment, guaranteeing the sheets keep up with their structure and construction under assorted natural circumstances.

The consideration of fire resistant synthetics further upgrades the wellbeing profile of FR4 sheets, making them appropriate for applications where fire security is fundamental. This trademark is especially vital in gadgets, where the gamble of warm occasions can present huge dangers.

Basically, FR4 sheets address an agreeable blend of hearty materials designed to convey unrivaled execution, dependability, and wellbeing across a range of requesting applications. Their flexibility and versatility highlight their significance as central parts in current modern cycles, driving advancement and progress across different areas.

Manufacturing Process

The assembling system of FR4 sheets includes a few successive moves toward guarantee the development of top caliber, dependable sheets:

1. Arrangement of Unrefined substances: Fiberglass materials are carefully sliced to the necessary size and completely cleaned to eliminate any pollutants or debasements.

2. Impregnation: The pre-arranged fiberglass materials go through impregnation with an Epoxy Resin Sheets blended in with explicit added substances customized to accomplish wanted properties, like fire retardancy and mechanical strength.

3. Laying and Layering: The impregnated fiberglass materials are fastidiously spread out in exact layers, with the quantity not entirely set in stone by the thickness determinations of the last FR4 sheet.

4. Squeezing and Relieving: The layered fiberglass gathering is moved to a press, where it goes through pressure under controlled intensity and strain conditions. This interaction enacts the relieving response of the epoxy sap, changing it into a strong state and shaping a thick, inflexible sheet.

5. Cooling and Wrapping up: When the relieving system is finished, the sheets are cooled to encompassing temperature. Last final details are applied, including managing of edges to accomplish exact aspects, and intensive assessment is directed to guarantee adherence to quality guidelines and consistency across all sheets.

By fastidiously following these assembling steps, FR4 sheets are created with outstanding mechanical strength, electrical protection properties, and fire retardancy, making them vital parts in different modern applications.

Properties and Quality Control

FR4 Epoxy Sheet brag a range of fundamental properties imperative for their horde applications, incorporating essential qualities like elasticity, compressive strength, and flexural strength. These properties are exposed to thorough testing conventions to learn consistence with severe industry norms, including those laid out by the Public Electrical Producers Affiliation (NEMA).

Rigidity alludes to the limit of FR4 sheets to endure pulling or extending powers without bursting. Compressive strength estimates their capacity to get through loads applied toward a path that packs the material, while flexural strength measures their protection from bowing or flexing stresses.

By sticking to the norms set out by associations like NEMA, producers guarantee that FR4 sheets meet indicated execution benchmarks, ensuring dependability and consistency across assorted applications. These principles act as benchmarks for quality affirmation, directing makers in the creation of FR4 sheets that convey ideal execution and strength in requesting functional conditions.

Through careful testing and adherence to laid out guidelines, FR4 sheets keep on filling in as imperative parts in different enterprises, giving powerful mechanical properties vital for the consistent activity of basic applications in hardware, aviation, car, and then some.

Applications of FR4 Epoxy Sheets

FR4 sheets are broadly acclaimed for their vigor and extraordinary protecting properties, delivering them imperative in a plenty of electrical protection applications. Regularly utilized in transformers, switchgear, aviation parts, and automated frameworks, FR4 sheets act as solid hindrances against electrical conductivity, protecting touchy parts from expected shortcircuits and electrical perils.

In addition, their capacity to endure raised temperatures and mechanical anxieties makes FR4 sheets profoundly pursued in businesses where flexibility is central. Whether in high-temperature conditions or exposed to thorough mechanical powers, FR4 sheets show wonderful sturdiness, guaranteeing continuous execution much under testing conditions.

The flexibility of FR4 sheets stretches out past customary electrical protection applications, tracking down utility in different areas that request strong and dependable materials. From aviation to car enterprises, FR4 sheets are valued for their capacity to convey steady execution and life span, going with them a favored decision for specialists and creators looking for trustworthy answers for their different applications. As a foundation of current designing, FR4 sheets keep on assuming a urgent part in molding mechanical headways across a bunch of businesses.

Quality and Customization

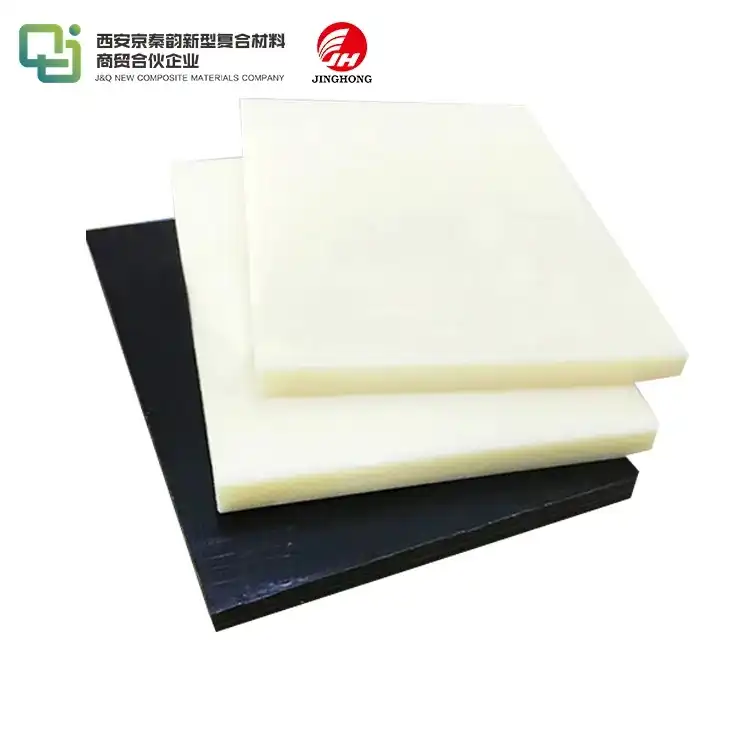

FR4 Epoxy Sheet are exceptionally versatile to different modern necessities, offering customization choices in thickness, size, and even tone. This adaptability permits makers to fit FR4 sheets to meet exact plan determinations, guaranteeing ideal execution in different applications.

Producers every now and again give CNC cutting administrations, utilizing trend setting innovation to unequivocally slice FR4 sheets to the ideal aspects. This ability empowers the production of complicated shapes and plans, taking care of the special requirements of every application.

Also, the capacity to redo FR4 sheets stretches out to variety determination, considering consistent incorporation into various item plans and feel. Whether for electrical protection in transformers or primary parts in aviation frameworks, FR4 sheets can be redone to match the particular necessities and visual inclinations of the end-client.

By offering customization choices, makers engage specialists and originators to upgrade the exhibition and presence of their items while keeping up with the excellent properties and unwavering quality related with FR4 sheets. This flexibility guarantees that FR4 stays a flexible and irreplaceable material across a large number of ventures and applications.

Call to Action: Contact Us

As a main provider with a GMP-ensured office, we offer an enormous stock of great FR4 epoxy sheets, complete with every single essential confirmation. We support OEM and furnish quick conveyance with vigorous bundling to guarantee item respectability. Our expert group is prepared to help your testing needs and assurance the best materials for your activities. For joint effort amazing open doors and more data on our item range, reach us at info@jhd-material.com.

For more detailed specifications and properties of FR4 materials, visit FR4 Material Guide and Curbell Plastics.