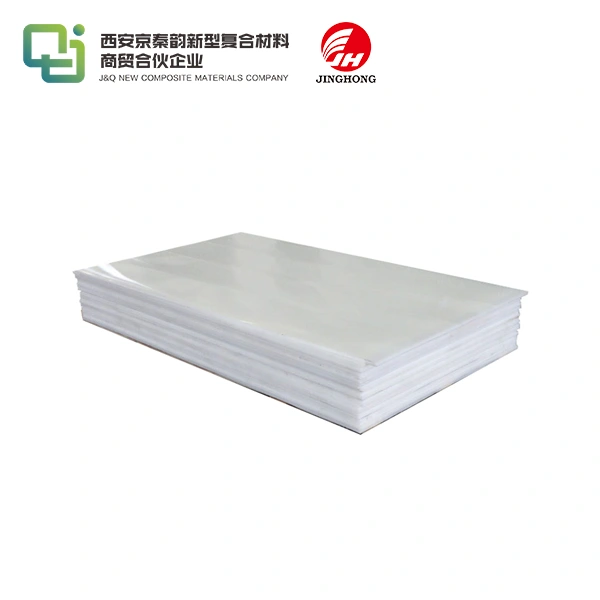

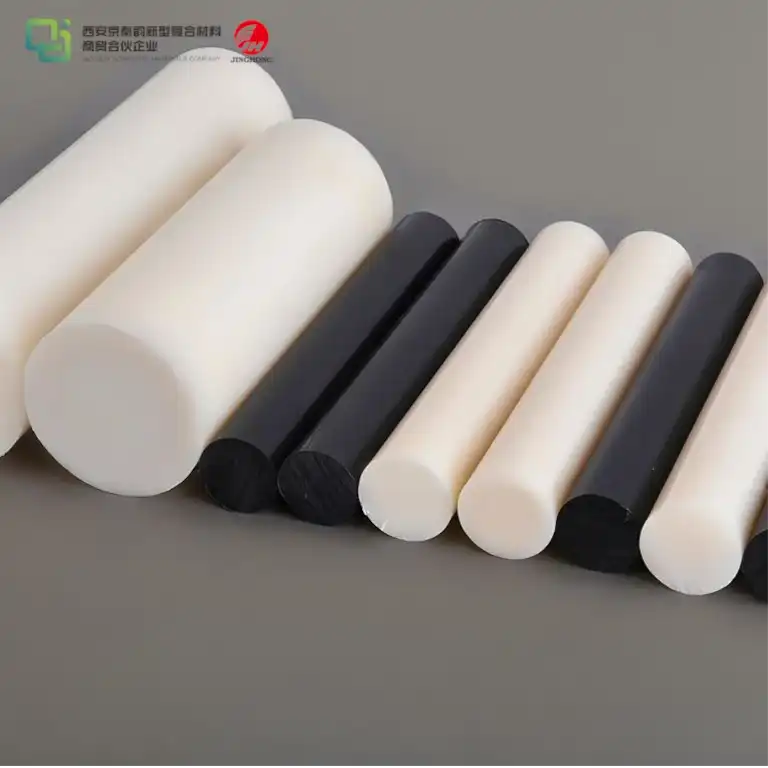

HDPE Board

Material:Polyethylene

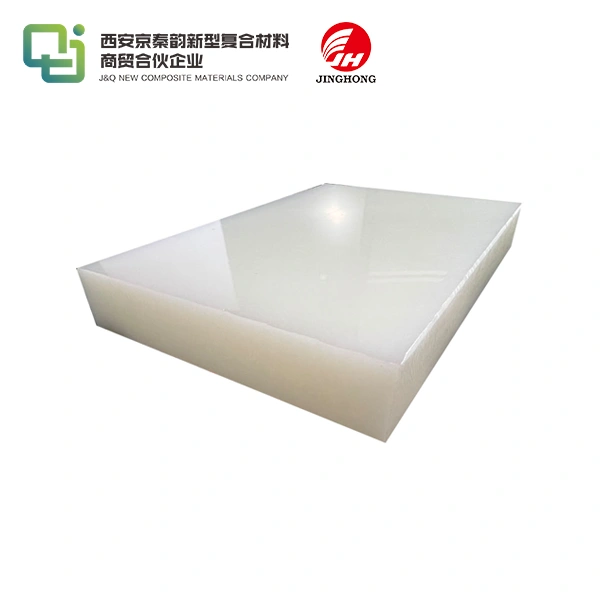

Color:White, Other color can be customized

Size: 1000mm * 2000mm, 1220mm*2440mm, 1300mm*2000mm, 1500mm*3000mm, Other sizes can be customized

Packaging: Regular packing, Protect by Pallet

Transportation: Ocean, Land, Air

Payment:T/T

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Production Description

HDPE board has excellent resistance to most domestic and industrial chemicals. Certain types of chemicals can cause chemical corrosion, such as corrosive oxidants (concentrated nitric acid), aromatic hydrocarbons (xylenes), and halogenated hydrocarbons (carbon tetrachloride). The polymer is non hygroscopic and has good water vapor resistance, and can be used for packaging purposes. HDPE has good electrical properties, especially the high dielectric strength of insulation, making it very suitable for wires and cables. Medium to high molecular weight grades have excellent impact resistance, even at - 40F low temperature. The unique characteristics of various grades of HDPE are the proper combination of four basic variables: density, molecular weight, molecular weight distribution and additives. Different catalysts are used to produce customized polymers with special properties. These variables are combined to produce HDPE grades for different purposes; Achieve the best balance in performance. It has good chemical stability and can resist the corrosion of most acids, alkalis, organic solutions and hot water. Good electrical insulation.

Property

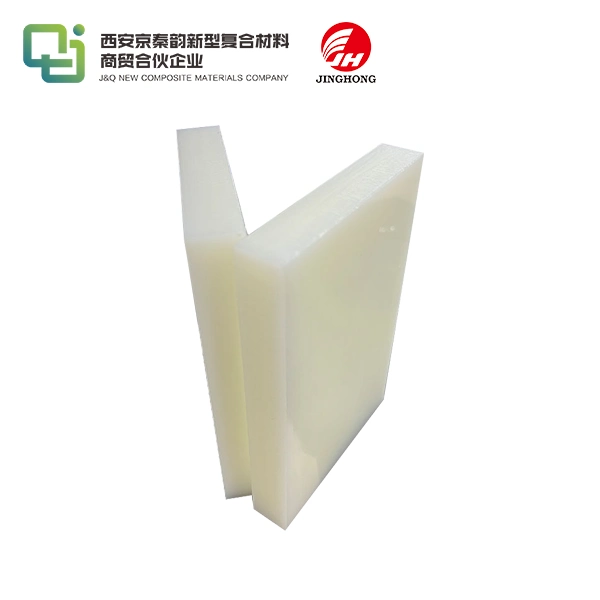

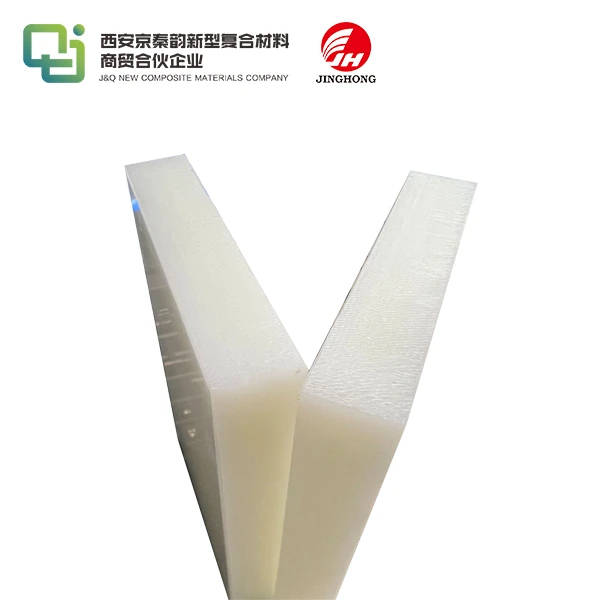

HDPE plastic sheet (high-density polyethylene board) has a melting point of about 130 ℃ and a relative density of 0.941~0.960. It has good heat resistance and cold resistance, good chemical stability, high rigidity and toughness, and good mechanical strength. The dielectric property and environmental stress cracking resistance are also good. The melting temperature is 220~260C. For materials with large molecules, it is recommended that the melting temperature range be 200~250C.

Application

Medical appliance parts, seals, cutting plates, sliding profiles It is widely used in chemical, machinery, chemical, power, clothing, packaging, food and other industries. It is widely used in gas transmission, water supply, sewage discharge, agricultural irrigation, fine particle solid transmission in mines, oil fields, chemical industry, post and telecommunications and other fields, especially in gas transmission.

Polyethylene plastic sheet is made of foamed polyethylene plastic particles. It has excellent sound absorption insulation sheet, water vapor permeability resistance and cut-off gas flow capacity, low water absorption and low thermal conductivity.

Rubber plastic sponge thermal insulation material is a soft high-grade thermal insulation and energy saving material, which is made of butadiene nitrile rubber and polyvinyl chloride with excellent performance as the main raw materials, together with various high-quality auxiliary materials, and foamed by a special process. It does not contain chlorofluorocarbons.

This product has excellent properties such as softness, bending resistance, cold resistance, heat resistance, flame retardancy, waterproof, low thermal conductivity, shock absorption and sound absorption. It can be widely used in central air-conditioning, construction, chemical, pharmaceutical, textile and other industries.

Drinking water and sewage pipes, hot water pipes, transport containers, pump and valve parts, medical appliance parts, seals, cutting plates, sliding profiles. It is widely used in chemical industry, machinery, electricity, clothing, packaging, food and other industries.

Technical Data for PE Sheet

|

No |

Test Items |

Unit |

Technical Indicators |

Test Result |

|

1 |

Density |

g/cm³ |

0.94~0.96 |

0.957 |

|

2 |

Tensile Yield Stress |

MPa |

≥22 |

22.1 |

|

3 |

Charpy Notched Impact Strength |

kJ/m² |

≥18 |

18.7(H) |

|

4 |

Change rate of longitudinal dimension * 100℃/1h |

% |

≤50 |

1.0 |

|

Hygienic requirements |

||||

|

5 |

Appearance |

Normal color, no odor, no impurities, etc |

||

|

6 |

Soaking Solution |

The immersion solution obtained from the migration test has no sensory deterioration such as turbidity, precipitation and odor |

||

|

7 |

Total migration (4% acetic acid, 70 ℃, 2h) |

mg/dm 3 |

2.0 |

Not Detected |

|

8 |

Consumption of potassium permanganate (water, 60 ℃, 2h) |

mg/kg |

1.0 |

Not Detected |

|

9 |

Heavy metals (calculated by PB, 4% acetic acid, 60 ℃, 2h) |

mg/kg |

1.0 |

Not Detected |

Factory

J&Q New Composite Material Group Co., Ltd is a national manufacturer of insulation materials and Epoxy Resin, Engineered Plastic. We have two factories. They are located in Heibei Province. One is Hongda Insulation Materials Factory was founded in 2000. Covering an area of 30000 square meters. Advanced process equipment, complete testing equipment. All of our equipment is fully automated production workshop. Mainly production is 3420 epoxy sheet grade B, Annual output of more than 13000 tons. it is the largest Grade B sheet manufacturer in China. And get honest and trustworthy unit and Consumer Satisfaction Trust Units and other honors issued by the government. we passed the ISO 9001quality management system certification.

The other is Hebei JingHong Electronic Technology Co., Ltd Covering an area of 66667 square meters. A total investment of 200 million CNY, annual output is 30,000 tons. JingHong is a new material company integrating scientific research, development, production, sales, and service. The main products are FR4 sheet,3240 epoxy sheet grade A, phenolic cotton sheet, Bakelite sheet, copper clad laminate, Epoxy Resin, and Engineered Plastic, which have strong insulation products development and production capacity. JingHong has the most advanced glue machine, thermal compressor, and a vertical upper glue machine specially equipped for FR4 sheets can ensure the best and most stable product quality.

We uphold quality first, integrity. Meanwhile, we have more than 20 years of experience in producing and selling insulating sheets and more than 10 years of export experience. Products are exported to Russia, Southeast Asia, the United States, Europe, and other countries, and the annual export volume accounts for 40% of the total export volume in China. What’s more, we have our own logistics company, so we can provide one-stop service. Look forward to long-team cooperation.

Certification

Exhibition

Packaging and Shipping

FAQ

Q: Are you a trading company or manufacturer?

A: We are a manufacturer.

Q: Can you give me a discount price?

A: It is depending on the quantity.

Q: Which certification do you have?

A: Our factory has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

Q: Can I get a free sample?

A: Free samples are available.

Q: How long is the delivery time?

A: Generally it is 10-15 days if the goods are in stock, or it is 5-10 days.

Q: What's the payment?

A:Payment<=1000USD, 100% in advance

Payment>=1000USD 30% TT advance, 70% TT before shipping.

Send Inquiry