What are the load-bearing capabilities of Flame Resistance FR4 Fiber Glass Laminate Sheets?

2024-07-15 14:27:57

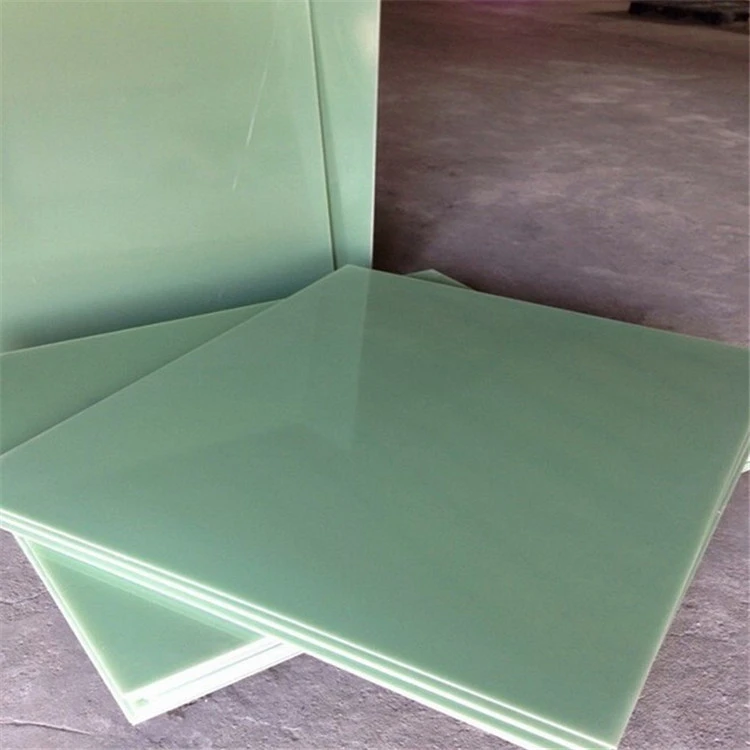

As a professional in the manufacturing industry, I often encounter inquiries about the load-bearing capabilities of Flame Resistance FR4 Fiber Glass Laminate Sheets. These sheets are widely used in various applications, ranging from electronics to aerospace, due to their excellent mechanical properties and resistance to heat and chemicals. In this comprehensive guide, I aim to delve into the intricacies of FR4 Fiber Glass Laminate Sheets, exploring their composition, load-bearing capacities, applications, safety considerations, and tips for choosing the right material.

Understanding the Composition of FR4 Fiber Glass Laminate Sheets

Flame Resistance FR4 Fiber Glass Laminate Sheets are composite materials composed of woven fiberglass cloth impregnated with epoxy resin. The fiberglass provides strength and rigidity, while the epoxy resin acts as a binding agent, enhancing durability and heat resistance. These sheets are manufactured through a process of layering fiberglass fabric and resin, followed by curing under high temperature and pressure to create a rigid laminate.

Evaluating Load-Bearing Capacities: Factors and Testing Methods

Deciding the load-bearing capabilities of FR4 Fiber Glass Cover Sheets includes considering different components such as thickness, fiber introduction, tar substance, and the nearness of fortifications like copper thwart. Testing strategies such as flexural testing, pliable testing, and compression testing are utilized to evaluate the material's mechanical properties beneath distinctive stacking conditions. Producers conduct thorough testing to guarantee that FR4 sheets meet industry measures and execution requirements.

Applications of FR4 Fiber Glass Cover Sheets in Different Industries

Flame Resistance FR4 Fiber Glass Laminate Sheets discover broad utilize over assorted businesses due to their flexibility and unwavering quality. In the hardware industry, they are commonly utilized as substrates for printed circuit sheets (PCBs), giving fabulous electrical cover and mechanical back for electronic components. Additionally, FR4 sheets are utilized in aviation, car, broadcast communications, and renewable vitality divisions for applications requiring tall quality, warm soundness, and fire resistance.

The car division too benefits from the special properties of FR4 fiber glass cover sheets. They are utilized in the generation of electronic control units (ECUs), sensor modules, and other basic electronic frameworks inside vehicles. FR4 covers give the essential electrical separator and basic bolster, guaranteeing the unwavering quality and life span of car gadgets. Moreover, their fire retardant characteristics upgrade vehicle security by lessening the hazard of fire in the occasion of electrical breakdowns. This makes FR4 an perfect fabric for the progressively advanced and electronically complex present day car industry, where both execution and security are crucial.

Furthermore, in the broadcast communications division, FR4 sheets are fundamental for fabricating solid and secure organizing gear, such as switches and switches.The material's stability and resistance to thermal and electrical stresses ensure consistent performance, which is vital in maintaining uninterrupted communication services. In the renewable energy sector, FR4 laminates are used in solar panel assemblies and wind turbine control systems, providing durable and flame-resistant solutions that contribute to the sustainability and efficiency of renewable energy technologies. The adaptability and high performance of FR4 fiber glass laminate sheets make them invaluable across these diverse industrial applications.

Ensuring Safety: Fire Resistance and Compliance Standards

Fire resistance is a basic thought when selecting materials for applications where fire risks are predominant. FR4 Fiber Glass Cover Sheets are famous for their fabulous fire-resistant properties, making them reasonable for utilize in situations where start sources may be show. These sheets are designed to withstand tall temperatures without compromising their basic astuteness, giving included security affirmation. It is fundamental to guarantee that FR4 sheets comply with pertinent security benchmarks such as UL 94 and IEC 60335 to ensure their fire-resistant performance.

Choosing the Right FR4 Fiber Glass Cover Sheets for Your Needs

Selecting the fitting FR4 Fiber Glass Cover Sheets requires cautious thought of particular application necessities, counting mechanical quality, warm conductivity, electrical separator, and natural conditions. It is fitting to counsel with experienced experts or trusted providers who can give custom-made arrangements based on your venture needs. Furthermore, confirming certifications and quality affirmations guarantees that you get dependable and compliant materials for your applications.

Contact us for all your Flame Resistance FR4 Fiber Glass Laminate Sheets needs! As a professional manufacturing supplier with a GMP factory, large inventory, and complete certificates, we offer OEM support, fast delivery, and tight packaging. Partner with us for high-quality materials and excellent service. Reach out to info@jhd-material.com to discuss your requirements and explore collaboration opportunities.

References:

1. "Understanding FR-4: What is FR-4 and What is it Used For?" - Altium

2. "Flame Retardant Epoxy Resins" - Comprehensive Composite Materials II

3. "Fire Performance of Glass Reinforced Epoxy Laminates" - Fire Technology

4. "Characterization and Analysis of Glass Fiber Reinforced Epoxy Composites" - Journal of Composite Materials

5. "UL 94 Flame Classifications" - Underwriters Laboratories