ABS Board

Material:Polyethylene

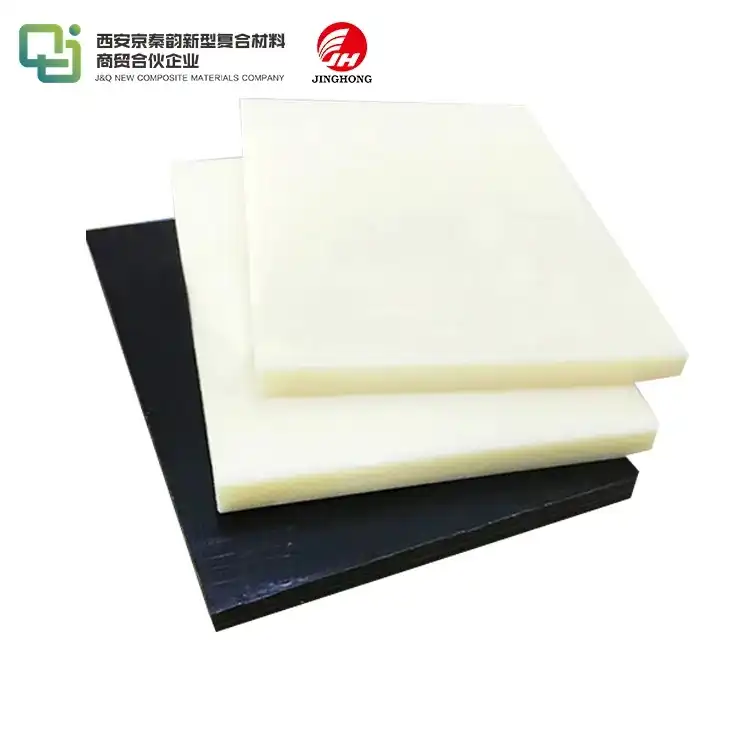

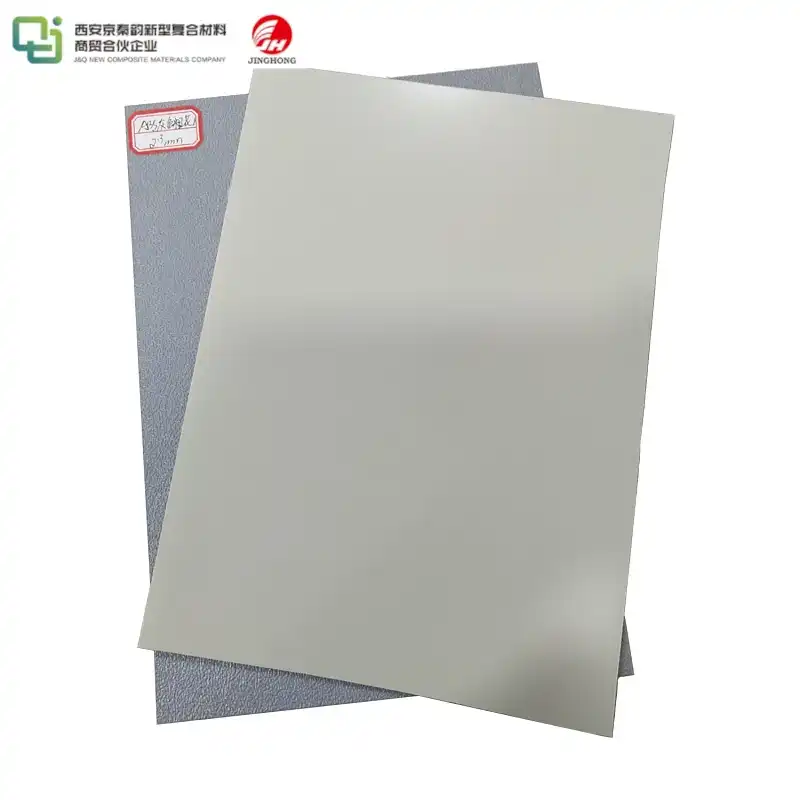

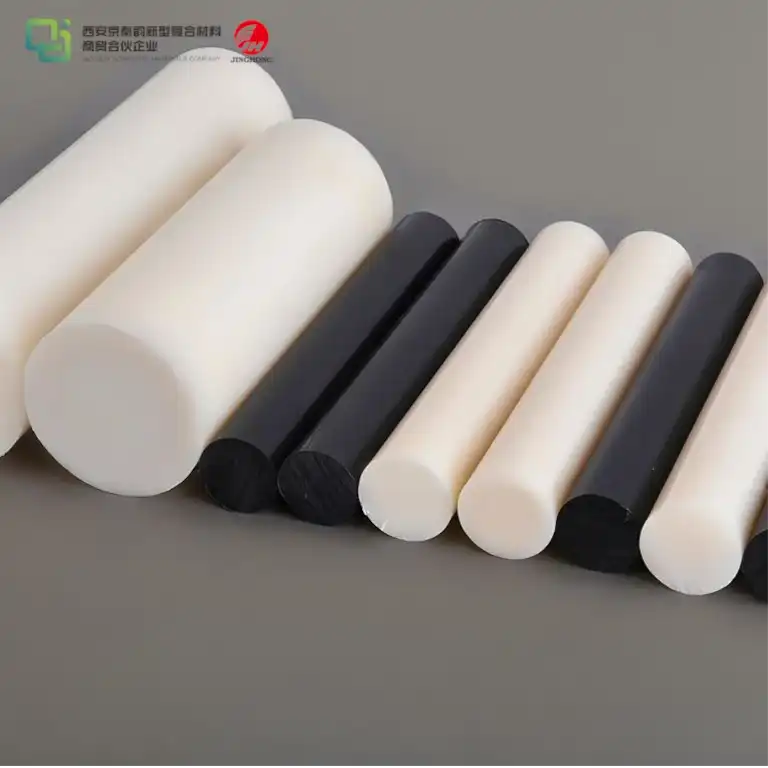

Color:White, beige, black, Other color can be customized

Size: 600*1200mm,1000*1000mm,1000*2000mm, Other sizes can be customized

Packaging: Regular packing, Protect by Pallet

Transportation: Ocean, Land, Air

Payment:T/T

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

ABS Board Product Attributes:

1. Excellent Mechanical Performance: ABS Board has high strength and rigidity, as well as good impact absorption, able to withstand external impacts without easy breakage.

2. Chemical Resistance: the board exhibits good resistance to various chemicals, allowing stable operation in complex working environments.

3. Weather Resistance: the board possesses good weather resistance, capable of long-term indoor and outdoor use without aging, deformation, or discoloration.

Specifications:

Common specifications include thickness ranging from 1mm to 100mm, width between 600mm to 2000mm, and length customizable based on customer requirements.

ABS Board Applications:

ABS Board finds extensive applications in industrial sectors including, but not limited to:

1. Electronics and Electrical: Used for manufacturing electronic casings, instrument panel components, etc.

2. Automotive Industry: Utilized for interior parts, body components, etc., in automotive manufacturing.

3. Building Decoration: Commonly employed in interior decorative panels, commercial signage, and other applications.

4. Medical Equipment: Applied in the production of medical equipment casings, isolation panels, and more.

In summary, ABS board, with its excellent mechanical performance, chemical resistance, and weather resistance, is suitable for various industrial applications. It can be customized according to customer requirements, ensuring stable performance and reliable quality as a type of engineering plastic product.

Technical Data for ABS Board

|

No |

Test Item |

Unit |

Test Result |

Test Method |

|

1 |

Density |

g/cm³ |

1.413 |

ASTM D792-2013 |

|

2 |

Tensile Strength |

Mpa |

66.6 |

GB/T 1040.2/1B-2006 |

|

3 |

Elongation Strength |

% |

24 |

GB/T 9341-2008 |

|

4 |

Bending Strength |

Mpa | 102 | GB/T 9341-2008 |

|

5 |

Flexural Modulus of Elasticity | Mpa | 2820 | GB/T 1043.1/1eA-2008 |

|

6 |

Charpy Notched Impact Strength | KJ/m² | 7.8 | GB/T 13520-1992 |

|

7 |

Ball Impact Strength | / | No Cracking | GB/T 1633-2000 |

|

8 |

Vicat Heat Resistance (1kg,50℃/h) | ℃ | 163 | GB/T 22789.1-2008 |

|

9 |

Heating Size Change Rate (longitudinal) | % | 0.08 | GB/T 22789.1-2008 |

|

10 |

Heating Size Change Rate (transverse) | % | 0.04 | GB/T 22789.1-2008 |

|

11 |

Rockwell Hardness (R) | / | 118 | GB/T 3398.2-2008 |

|

12 |

Surface Resistance Coefficient | Ω | 8.5 x 10^12 | GB/T 31838.2-2019 |

|

13 |

Volume Resistance Coefficient | Ω.m | 1.3 x 10^12 | GB/T 31838.2-2019 |

|

14 |

Dielectric Constant (1MHZ) | / | 3.7 | GB/T 1409-2006 |

| 15 | Dielectric Loss(1MHZ) | / | 0.055 | GB/T 1409-2006 |

| 16 | Dielectric Strength | KV/mm | 6.93 | GB/T 1408.1-2016 |

| 17 | Friction Coefficient | / | 0.18 | GB/T 3960-2016 |

Factory

J&Q New Composite Material Group Co., Ltd is a national manufacturer of insulation materials and Epoxy Resin, Engineered Plastic. We have two factories. They are located in Heibei Province. One is Hongda Insulation Materials Factory was founded in 2000. Covering an area of 30000 square meters. Advanced process equipment, complete testing equipment. All of our equipment is fully automated production workshop. Mainly production is 3420 epoxy sheet grade B, Annual output of more than 13000 tons. it is the largest Grade B sheet manufacturer in China. And get honest and trustworthy unit and Consumer Satisfaction Trust Units and other honors issued by the government. we passed the ISO 9001quality management system certification.

The other is Hebei JingHong Electronic Technology Co., Ltd Covering an area of 66667 square meters. A total investment of 200 million CNY, annual output is 30,000 tons. JingHong is a new material company integrating scientific research, development, production, sales, and service. The main products are FR4 sheet,3240 epoxy sheet grade A, phenolic cotton sheet, Bakelite sheet, copper clad laminate, Epoxy Resin, and Engineered Plastic, which have strong insulation products development and production capacity. JingHong has the most advanced glue machine, thermal compressor, and a vertical upper glue machine specially equipped for FR4 sheets can ensure the best and most stable product quality.

We uphold quality first, integrity. Meanwhile, we have more than 20 years of experience in producing and selling insulating sheets and more than 10 years of export experience. Products are exported to Russia, Southeast Asia, the United States, Europe, and other countries, and the annual export volume accounts for 40% of the total export volume in China. What's more, we have our own logistics company, so we can provide one-stop service. Look forward to long-team cooperation.

Certification

Exhibition

Packaging and Shipping

FAQ

Q: Are you a trading company or manufacturer?

A: We are a manufacturer.

Q: Can you give me a discount price?

A: It is depending on the quantity.

Q: Which certification do you have?

A: Our factory has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

Q: Can I get a free sample?

A: Free samples are available.

Q: How long is the delivery time?

A: Generally it is 10-15 days if the goods are in stock, or it is 5-10 days.

Q: What's the payment?

A:Payment<=1000USD, 100% in advance

Payment>=1000USD 30% TT advance, 70% TT before shipping.

Send Inquiry