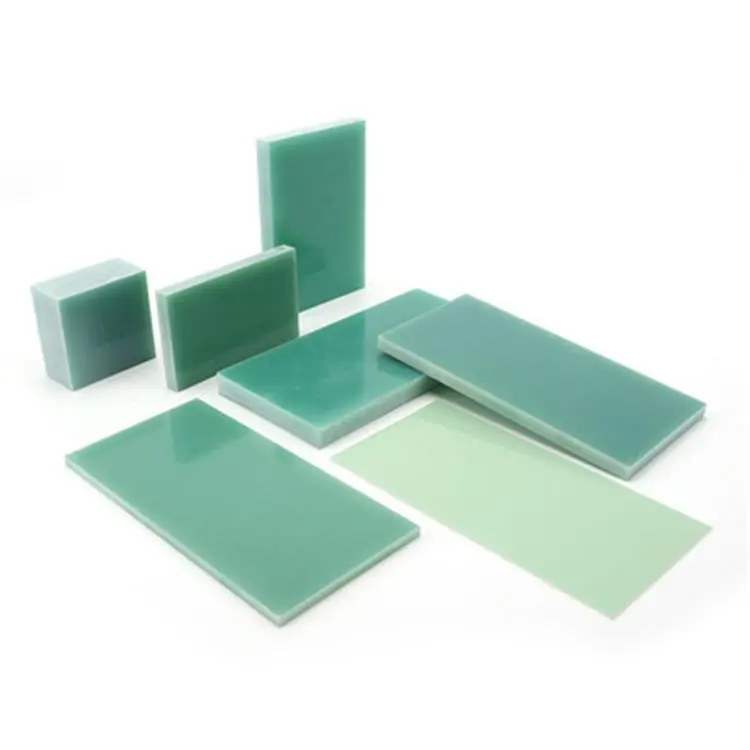

Can a Flame Resistance FR4 Fiber Glass Laminate Sheet withstand fire?

2024-05-15 13:56:51

Flame Resistance FR4 Fiber Glass Laminate Sheet is renowned for its exceptional flame resistance, making it a preferred material in various applications where fire safety is paramount. Here, we'll explore the capabilities of FR4 in withstanding fire, supported by insights into its composition, properties, and typical uses.

Understanding FR4 Material Composition

FR4, a widely used material in electronics and electrical engineering, derives its name from "Flame Retardant 4." This designation indicates its flame-retardant properties and its compliance with specific standards. Understanding its composition sheds light on its properties and applications:

Fiberglass Cloth:FR4 is primarily composed of a woven fiberglass cloth. Fiberglass is a lightweight, durable, and flexible material made from fine glass fibers. The fiberglass cloth serves as the reinforcement in FR4. It provides mechanical strength, rigidity, and dimensional stability to the material.

Epoxy Resin Binder:The fiberglass cloth in FR4 is impregnated with an epoxy resin binder. Epoxy resins are thermosetting polymers known for their excellent adhesion, chemical resistance, and mechanical properties. The epoxy resin matrix holds the fiberglass cloth together, providing cohesion and stability to the composite material.

Flame Retardant Additives:FR4 materials incorporate flame retardant additives to enhance their fire resistance. These additives can include brominated compounds, phosphorous compounds, or other chemical agents that inhibit the spread of flames and reduce smoke generation. The flame retardant additives help FR4 meet safety standards and regulations, making it suitable for use in applications where fire risk is a concern.

Other Additives:Depending on specific formulations and manufacturer preferences, FR4 may contain additional additives to modify its properties. These additives could include fillers for reinforcement, antioxidants for stability, or pigments for coloration. The selection and concentration of additives can influence various characteristics of FR4, such as mechanical strength, thermal stability, and electrical properties.

Composite Structure:FR4 is produced by layering multiple sheets of fiberglass cloth impregnated with epoxy resin and then subjecting them to heat and pressure to cure the resin and bond the layers together.The resulting composite structure exhibits a balance of properties, including electrical insulation, mechanical strength, thermal stability, and flame resistance.

Applications

Flame Resistance FR4 Fiber Glass Laminate Sheet is widely used in printed circuit boards (PCBs), where it serves as the substrate for mounting electronic components and providing electrical connections.

It is also utilized in electrical insulation components, structural parts, thermal insulating materials, and various other applications where a combination of strength, insulation, and flame resistance is required.

Understanding the composition of FR4 provides insight into its properties and versatility, making it a popular choice in diverse industries ranging from electronics manufacturing to aerospace engineering.

Applications Beyond Fire Resistance:Due to its robust properties, FR4 is widely used in printed circuit board (PCB) manufacturing, where it acts as an insulator and structural support. Its excellent electrical insulation properties and mechanical durability also make it suitable for aerospace, automotive, and industrial equipment (FR4 Material) (Jaco Products, Inc.).

Flame Resistance Properties

The flame resistance properties of FR4 are essential for ensuring safety in various applications, particularly in electronics and electrical engineering where fire hazards can pose significant risks. Here's an overview of FR4's flame resistance properties:

Flame Retardant Additives:FR4 materials are formulated with specific flame retardant additives to reduce their flammability and inhibit the spread of flames. These additives can include halogenated compounds (e.g., brominated flame retardants), phosphorous compounds, or other chemical agents that disrupt the combustion process. The incorporation of flame retardant additives enhances FR4's ability to withstand exposure to flames and reduces the likelihood of ignition.

Reduced Flammability:FR4 materials exhibit significantly reduced flammability compared to non-flame-retardant alternatives. When subjected to a flame source, FR4 typically resists ignition and combustion, limiting the spread of fire and reducing the risk of property damage or injury.

Low Smoke Generation:In addition to inhibiting flames, FR4 formulations are designed to minimize smoke generation during combustion. Low smoke generation is crucial for maintaining visibility and facilitating safe evacuation in the event of a fire.

Compliance with Standards:FR4 materials are manufactured to meet specific flame resistance standards and regulations established by industry organizations and governmental agencies. Compliance with standards ensures that FR4 products adhere to prescribed safety requirements and performance criteria, providing assurance of their flame resistance properties.

Applications in Fire-Prone Environments:Due to their flame resistance properties, FR4 materials are commonly used in applications where fire safety is paramount, such as electrical enclosures, switchgear, control panels, and printed circuit boards (PCBs). The use of FR4 helps mitigate the risk of fire propagation and enhances the overall safety of electronic and electrical systems.

While FR4 materials offer notable flame resistance properties, it's essential to consider other factors such as material thickness, environmental conditions, and the presence of additional combustible materials in the vicinity. Regular testing and adherence to safety guidelines are necessary to ensure the continued effectiveness of FR4 in fire-prone environments.

Thermal and Mechanical Performance

FR4 is capable of withstanding temperatures up to 140°C, and its high glass transition temperatures can range from 115°C to as high as 200°C depending on the specific formulation and manufacturing process used.

Its thermal stability makes it ideal for environments where heat is generated, such as in electronic applications (Wikipedia) (pcbknow | Everything PCB !).

Comparing FR4 with Other Materials

FR4 is often compared with G10, another type of epoxy laminate. While G10 shares many of the mechanical and insulating properties of FR4, it lacks the flame retardant additives that make FR4 suitable for fire-prone environments.

Therefore,Flame Resistance FR4 Fiber Glass Laminate Sheet is generally recommended where enhanced fire resistance is required (Current Inc) (Jaco Products, Inc.).

Conclusion: Reliability and Professional Supply

FR4's ability to resist fire, combined with its mechanical and thermal stability, makes it a reliable choice for a wide range of applications.

Are you seeking a professional manufacturing partner ? Look no further! We are a trusted supplier with a GMP-certified factory, extensive inventory, and comprehensive certifications. Our services include OEM support, fast delivery, meticulous packaging, and testing support.

Let's collaborate to bring your projects to life! Contact us at info@jhd-material.com.