Can a Flame Resistance FR4 Fiber Glass Laminate Sheet be used for chemical processing equipment?

2024-06-13 16:41:46

1. Understanding FR4 Fiber Glass Laminate Sheets

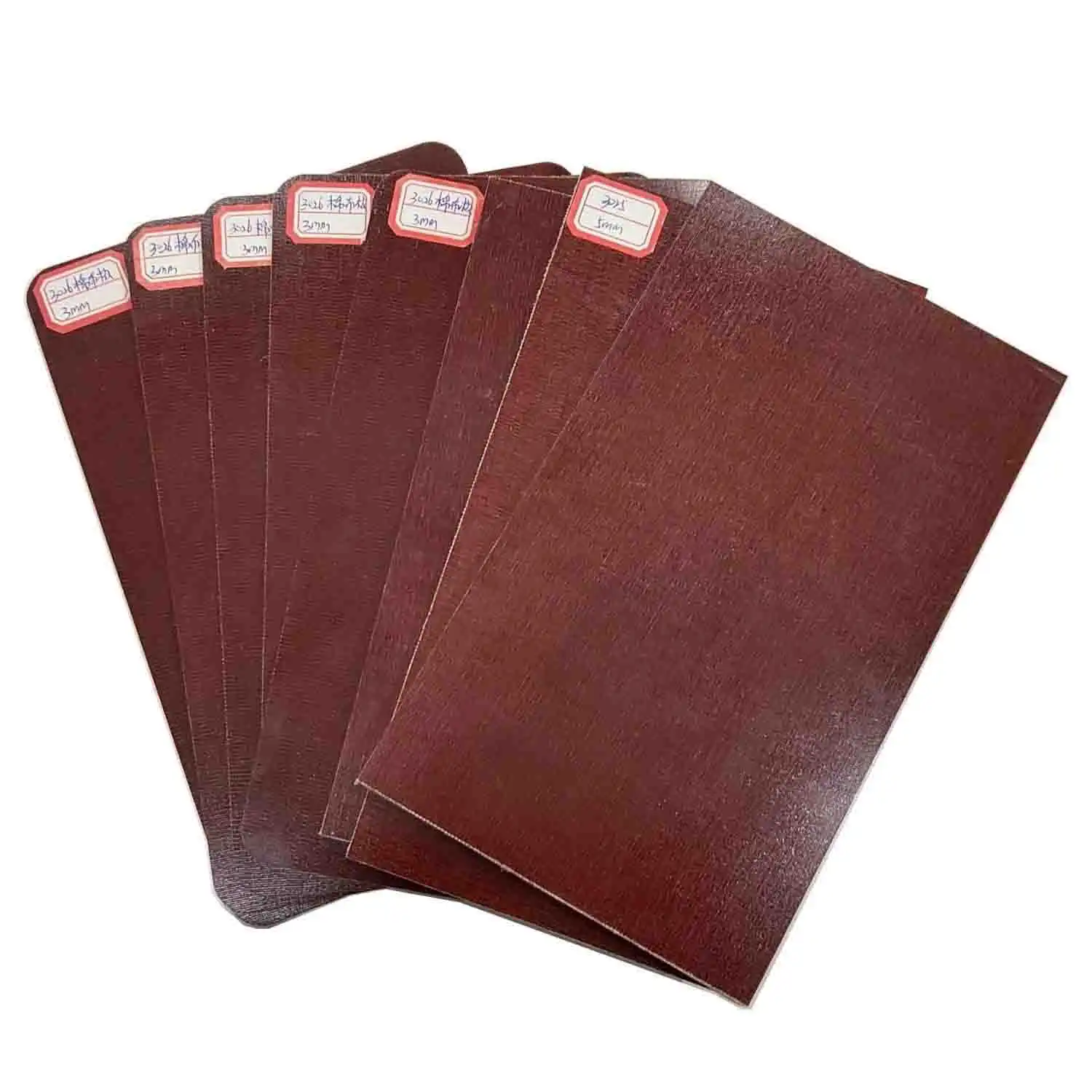

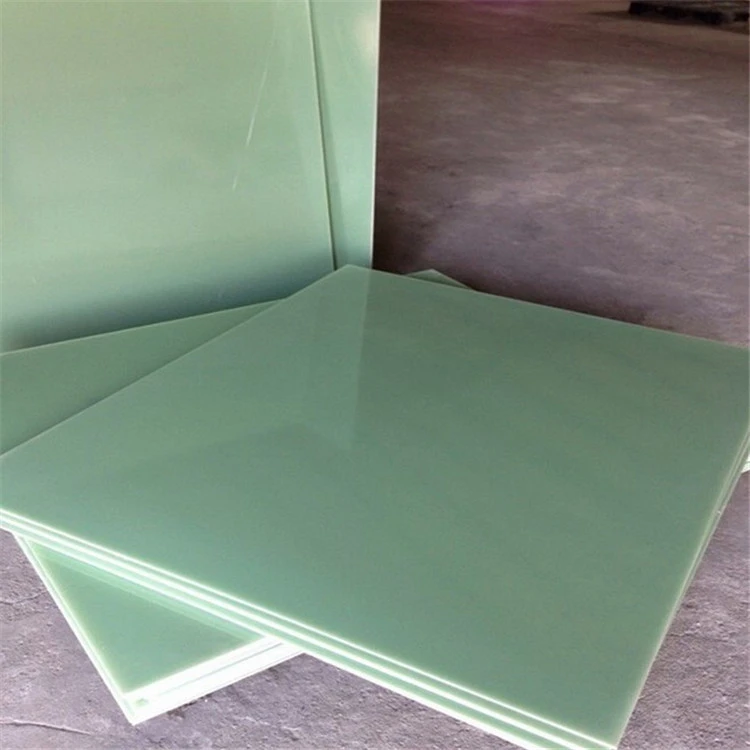

Flame Resistance FR4 Fiber Glass Laminate Sheet is a grade of the NEMA (National Electrical Manufacturers Association) classification for epoxy-based laminate sheets. These sheets are commonly used in electronic applications due to their excellent electrical insulation properties. FR4 sheets are composed of woven fiberglass cloth impregnated with an epoxy resin binder, making them highly durable and resistant to heat and moisture.

2. Chemical Resistance Properties of FR4 Fiber Glass Laminate Sheets

When considering the utilize of Flame Resistance FR4 Fiber Glass Laminate Sheets in chemical preparing hardware, it's basic to get it their chemical resistance properties. Whereas FR4 sheets offer amazing resistance to numerous chemicals, counting acids, bases, and solvents commonly found in mechanical settings, their resistance can change depending on the particular chemicals and concentrations included. It's significant to counsel with the producer or provider to guarantee compatibility with the chemicals utilized in the process.

3. Mechanical Quality and Warm Stability

In expansion to chemical resistance, the mechanical quality and warm steadiness of FR4 fiber glass cover sheets play a imperative part in their appropriateness for chemical handling gear. These sheets show tall mechanical quality, making them competent of withstanding physical stresses and weights experienced in mechanical situations. Moreover, FR4 sheets have fabulous warm solidness, guaranteeing they can withstand hoisted temperatures without compromising their auxiliary integrity.

The mechanical quality of FR4 fiber glass cover sheets is especially imperative in applications where the fabric will be subjected to steady utilize or overwhelming loads. For illustration, in chemical handling gear, the materials utilized must be able to handle the weight of chemicals, as well as any extra stretch caused by blending or mixing forms. The tall malleable and compressive quality of FR4 guarantees that it can keep up its execution indeed beneath such requesting conditions, decreasing the probability of physical disappointments that may lead to hardware downtime or chemical spills.

The warm steadiness of FR4 fiber glass cover sheets is moreover significant in chemical preparing situations. Numerous chemical responses and forms happen at lifted temperatures, and the materials utilized must be able to work dependably without debasing or losing their mechanical properties.The ability of FR4 to maintain its dimensions and structural integrity at high temperatures makes it suitable for use in environments where temperature fluctuations are common, such as in autoclaves, furnaces, and heat exchangers. This thermal stability not only ensures the safety and effectiveness of the chemical process but also extends the lifespan of the equipment by preventing thermal expansion and contraction issues.

In summary, the combination of mechanical strength and thermal stability in FR4 fiber glass laminate sheets provides significant advantages in the construction of chemical processing equipment. These properties allow the material to perform reliably in harsh industrial environments, ensuring the safe and efficient operation of chemical processes while minimizing maintenance needs and potential downtime.

4. Considerations for Selecting FR4 Fiber Glass Laminate Sheets

When selecting FR4 fiber glass cover sheets for utilize in chemical handling gear, a few variables must be considered. These incorporate the particular chemicals included in the handle, working temperatures and weights, mechanical stresses, and administrative necessities. It's fundamental to work closely with the producer or provider to assess these components and select the most reasonable FR4 fabric for the application.

5. Application Illustrations and Case Studies

To outline the viable utilize of FR4 fiber glass cover sheets in chemical preparing hardware, let's consider a few application illustrations and case ponders. For occasion, FR4 sheets are commonly utilized as protection materials in chemical reactors, capacity tanks, and channeling frameworks, where they give electrical separator, mechanical bolster, and chemical resistance. Case ponders enumerating fruitful applications of FR4 sheets in different chemical handling scenarios can offer profitable experiences into their execution and reliability.

Another case ponder highlights the utilize of FR4 sheets in pharmaceutical fabricating offices. Here, the fabric was utilized in the development of cleanroom dividers and ceilings due to its smooth surface, which encourages simple cleaning and minimizes the collection of contaminants. The chemical resistance of FR4 moreover guarantees that it does not respond with or assimilate any of the dynamic pharmaceutical fixings, keeping up the judgment of the fabricating handle. Also, the fire resistance of FR4 given an included security advantage, complying with strict fire security controls in these environments.

These cases illustrate the flexibility and unwavering quality of Flame Resistance FR4 Fiber Glass Laminate Sheet in different chemical handling applications. By leveraging the special properties of FR4, engineers and designers can plan more successful and secure chemical handling gear, contributing to progressed operational proficiency and compliance with industry benchmarks.

Contact us:

Are you in need of high-quality Flame Resistance FR4 Fiber Glass Laminate Sheet for your chemical processing equipment? Look no further! We are a professional manufacturing supplier with a GMP factory, large inventory, and complete certificates to meet your requirements. We support OEM orders, offer fast delivery, and ensure tight packaging to protect your products during transit. Contact us at info@jhd-material.com to discuss your needs and explore how we can support your business.

References:

1. National Electrical Manufacturers Association (NEMA) - https://www.nema.org/

2. "Understanding the Properties of FR4 Laminate" - Electronic Design, https://www.electronicdesign.com/power/understanding-properties-fr4-laminate

3. "FR-4 (or FR4) is a NEMA grade designation for glass-reinforced epoxy laminate material" - Wikipedia, https://en.wikipedia.org/wiki/FR-4

4. "Epoxy/Glass Laminate - FR-4" - TTM Technologies, https://www.ttm.com/wp-content/uploads/2021/06/Epoxy-Glass-Laminate-FR4-1.pdf