The four characteristics of halogen-free FR4 epoxy sheet

2023-10-25

The four characteristics of halogen-free FR4 epoxy sheet

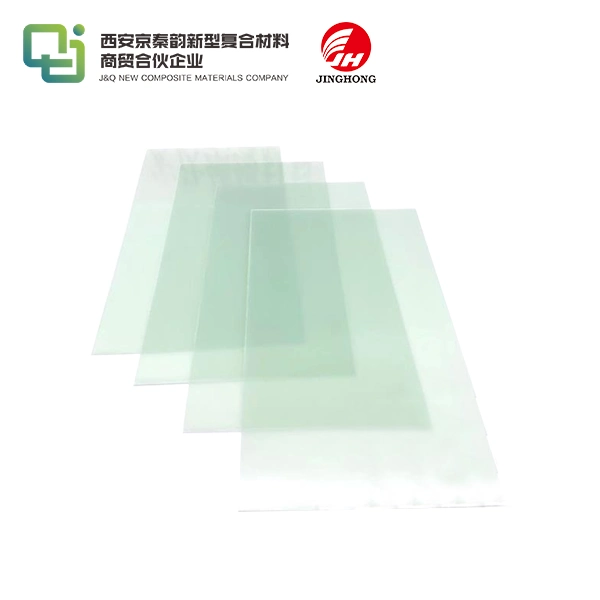

FR-4 halogen-free epoxy board is made by hot-pressing electronic-grade glass fiber impregnated with halogen-free epoxy resin. It has a yellow color and is primarily used as an insulating structural component in electrical and motor equipment. Since it does not contain halogens (fluorine, chlorine, bromine, iodine, arsenic), it does not produce toxic gases when burned, meeting green production requirements.

Its advantages are:

Firstly, environmental protection. In recent years, environmental pollution has become severe, and many areas have experienced haze weather. People are increasingly concerned about environmental protection, and FR-4 halogen-free epoxy board is non-toxic and environmentally friendly.

Secondly, high temperature resistance. FR-4 halogen-free epoxy board has good heat resistance and can withstand temperatures up to 150℃.

Thirdly, insulation. The breakdown voltage of FR-4 halogen-free epoxy board can reach up to 40KV. Although China's electricity consumption is increasing and the voltage is gradually rising, there is still a gap to reach the breakdown voltage of FR-4 epoxy board.

Fourthly, water absorption. It can effectively prevent moisture, with a long storage time.

The explanation of the three electrical breakdown performances of FR4 epoxy sheet

The reliability and service life of the winding on FR4 epoxy sheet largely depend on the performance of the insulation material. The basic requirements for insulation material performance include electrical, thermal, and mechanical properties. This article will briefly introduce the electrical properties of insulation materials, including breakdown strength, insulation resistance, dielectric constant, and dielectric loss. This article will explain the three types of electrical breakdown performance of FR4 epoxy sheet.

Insulation material breakdown strength is expressed in kilovolts per millimeter by dividing the thickness of the insulation material at the breakdown point by the breakdown voltage. Insulation breakdown can generally be divided into three forms: electrical breakdown, thermal breakdown, and discharge breakdown.

FR4 epoxy sheet electrical breakdown performance occurs when charged particles inside the insulation material move violently under the influence of a strong electric field, causing collisions and ionization, breaking down the molecular structure, and ultimately resulting in electrical breakdown. The breakdown voltage increases linearly with the thickness of the material, and in a uniform electric field, the breakdown strength is generally independent of the duration of the voltage pulse unless the pulse is shorter than 10 seconds.

FR4 epoxy sheet thermal breakdown performance occurs when heat is generated inside the insulation material due to dielectric losses under the action of an alternating electric field. If the heat cannot be dissipated in time, the temperature inside the material will rise, causing molecular structure damage and breakdown. The breakdown voltage decreases as the ambient temperature increases, the material thickness increases, and the heat dissipation conditions deteriorate. When the frequency increases, the dielectric loss increases, and the breakdown strength also decreases.

FR4 epoxy sheet discharge breakdown performance occurs when bubbles contained inside the insulation material discharge due to ionization under the action of a strong electric field, and impurities vaporize due to heating, producing bubbles, which further develop the discharge, leading to the breakdown of the entire material.

Insulation breakdown often involves all three forms mentioned above, making it difficult to distinguish them. Impregnating insulation materials with insulating varnish or adhesive can improve the electric field distribution and increase the breakdown strength, as well as improve heat dissipation conditions to increase the thermal breakdown strength.

What is the critical value of epoxy board in an electric field?

When the electric field strength applied to the epoxy board material exceeds the critical value, the current passing through the insulation material increases dramatically, causing the insulation material to rupture or decompose, completely losing its insulating properties. This phenomenon is called insulation breakdown. The voltage at which breakdown occurs is called the breakdown voltage, and the electric field strength at breakdown is called the breakdown strength, expressed in kV/mm.

Solid epoxy board breakdown can generally be divided into three forms: electrical breakdown, thermal breakdown, and discharge breakdown. Under the action of a strong electric field, charged particles inside the insulation material move violently, causing collisions and ionization, breaking down the molecular structure, increasing conductivity, and ultimately causing electrical breakdown. Under the action of an alternating electric field, heat is generated inside the insulation material due to dielectric losses. If the heat cannot be dissipated in time, the temperature inside the material will rise, causing molecular structure damage and breakdown, known as thermal breakdown. Discharge breakdown occurs when bubbles contained inside the insulation material discharge due to ionization under the action of a strong electric field, and impurities vaporize due to heating, producing bubbles, which further develop the discharge, leading to the breakdown of the entire material.

Breakdown voltage refers to the voltage at which the epoxy board specimen undergoes breakdown during a continuous voltage test under specified test conditions. Electrical strength refers to the quotient of the breakdown voltage and the distance between the two electrodes to which the voltage is applied under specified test conditions. Electrical strength test results can be used to detect changes or deviations in performance relative to normal values caused by process changes, aging conditions, or other manufacturing or environmental conditions.