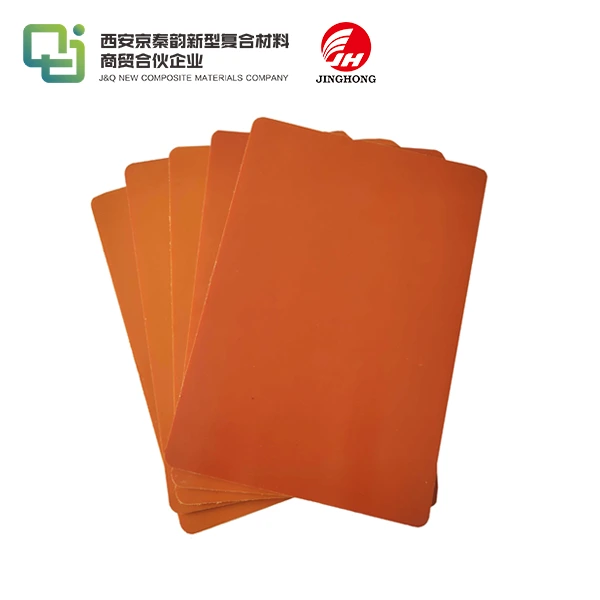

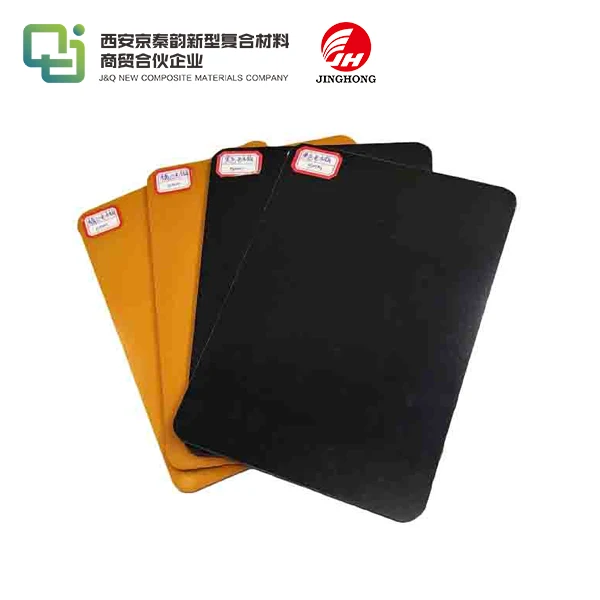

Bakelite Board

Basic Information:

Brand: Hongda

Materials: Phenolic Resin

Nature Color: Black and Orange

Thickness: 2mm --- 100mm

Regular Size: 1040mm*2080mm

Custom Size: 1220mm*2440mm

Packaging: Regular packing, Protect by Pallet

Productivity: 13000 Tons per year

Transportation: Ocean, Land, Air

Payment: T/T

MOQ: 500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Production Description

Bakelite board is a hard, dense industrial laminate material made by applying heat and pressure to layers of paper or glass cloth impregnated with synthetic resin. The resulting material is highly durable and resistant to heat, electricity, and various chemicals. Bakelite board is commonly used in a range of industrial applications due to its excellent mechanical and electrical properties.

Product Features:

High Strength: Bakelite board has extremely high strength and hardness, able to withstand a great deal of pressure and weight.

Heat Resistant: Bakelite board can withstand high temperatures without deforming or melting.

Excellent Insulation: Bakelite board is an excellent electrical insulating material, suitable for use in high voltage and high frequency applications.

Chemical Resistant: Bakelite board has good resistance to acids, alkalis and other chemical substances.

Product Applications:

Electrical Equipment: Bakelite board is widely used in the field of electrical equipment, such as switches, outlets, transformers, etc.

Mechanical Manufacturing: Bakelite board can be used to manufacture mechanical parts and industrial equipment components, such as gears, bearings, bridge brackets, etc.

Automotive Manufacturing: Bakelite board is used in the manufacture of automotive interiors, such as steering wheels, door handles, etc.

Other Fields: Bakelite board can be used to manufacture furniture, stationery, and more.

Technical Data

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Water Absorption |

mg |

115 |

GB/T 1303.2-2009 |

|

2 |

Density |

g/cm3 |

1.33 |

|

|

3 |

Insulation Resistance after Soaking |

Ω |

2.1*108 |

|

|

4 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

2.7 |

|

|

5 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

KV |

11.8 |

|

|

6 |

Tensile Strength |

MPa |

119 |

|

|

7 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

3.99 |

|

|

8 |

Vertical Layer Modulus of Elasticity in Flexure (155℃ ± 2℃) |

MPa |

3.98*103 |

|

|

9 |

Bending Strength Perpendicular to Laminations |

MPa |

168 |

|

|

10 |

Adhesive Strength |

N |

3438 |

GB/T 1303.6-2009 |

|

REMARK: 1. NO.1 the sample size is (49.78~49.91) mm * (50.04~50.11) mm * (2.53~2.55) mm; 2. NO.4 the sample thickness is (2.12~2.15) mm; 3. NO.5 the sample size is (100.60~100.65) mm * (25.25~25.27) mm * (10.15~10.18) mm; 4. NO.10 the sample size is (25.25~25.58) mm * (25.23~25.27) mm * (10.02~10.04) mm; |

||||

Process Part

We can provide CNC machining service as your requirement, such as engraving and cutting.

Production Process

|

|

Package and Shipping

Send Inquiry