What is the difference between FR4 and PTFE?

2024-07-16 16:08:28

Introduction

In the field of printed circuit boards (PCBs), FR4 epoxy is notable for its strength, sturdiness, and remarkable electrical properties. It is also used a lot. This material is used as the base for a lot of electronic devices because it can provide reliable mechanical support and good electrical insulation. In any case, understanding how FR4 examines to various materials like PTFE (Polytetrafluoroethylene) is fundamental for specialists drew in with PCB plan and collecting. Such data assists in making informed decisions that with canning generally influence the show, relentless quality, and cost-suitability of the last electronic things.

We compare and contrast the advantages of PTFE and FR4 in a variety of contexts and examine their distinct properties and applications in this comprehensive article. Current electronic gadgets depend on printed circuit sheets (PCBs), which act as stages for the mechanical help and electrical associations between various electronic parts. The choice of the appropriate PCB material is a fundamental decision that can have a significant impact on the general usefulness, lifespan, and financial viability of electronic structures.

In the production of PCBs, two of the most frequently utilized materials are PTFE and FR4. Despite the fact that both materials play crucial roles in the business, they differ particularly in terms of their structure, inherent qualities, and ideal use cases. Understanding these qualifications is major for subject matter experts, organizers, and makers who mean to update their arrangements and select the most sensible material for unequivocal applications. In the going with sections, we will guide a through and through assessment of FR4 and PTFE, taking a gander at their different resources, obstructions, and the circumstances where each material succeeds. By doing this, we want to make it more obvious how these materials assist with progressing electronic innovation today.

Why is FR4 used for PCBs?

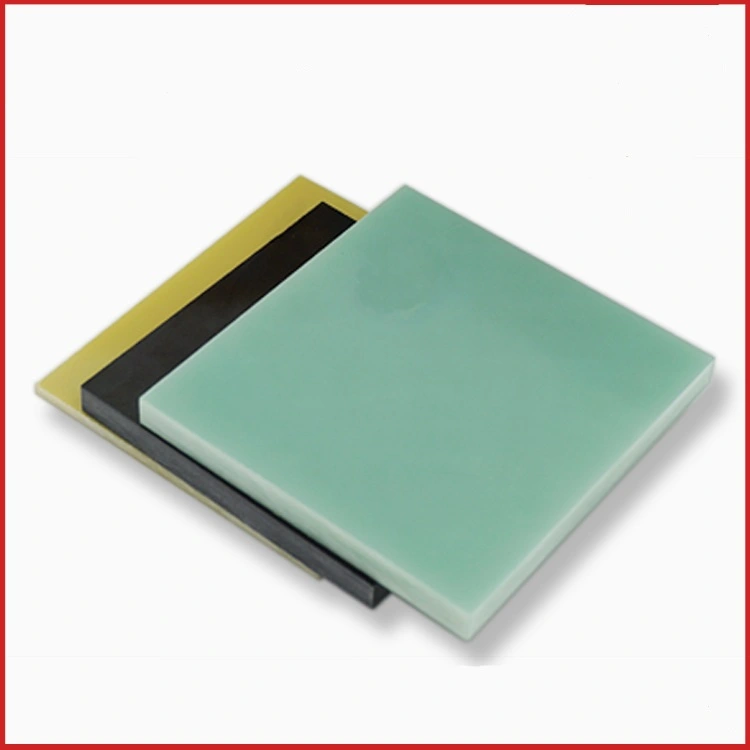

Due to its exceptional properties and dependability, FR4, also known as Flame Retardant 4, is frequently utilized in the manufacturing of printed circuit boards (PCBs). It is a type of epoxy-reinforced glass-reinforced laminate that is made of woven fiberglass cloth that has been coated with an epoxy resin binder.

The essential justification for involving FR4 in PCBs is its extraordinary mechanical strength. The reinforced PCB can withstand mechanical stresses and strains during operation and handling thanks to the woven fiberglass cloth. This guarantees that the PCB stays in salvageable shape and can get through the afflictions of different applications.

In addition, FR4 possesses excellent dimensional stability, which means that it remains the same size and shape regardless of the temperature or humidity. This property is vital for PCBs as it guarantees predictable electrical associations among parts and forestalls twisting or contortion that could prompt execution issues.

One more huge benefit of FR4 is its high protection from intensity and synthetics. The epoxy tar cover utilized in FR4 offers warm strength, permitting the PCB to work dependably even in raised temperature conditions. For electronic devices that generate heat during operation, this is especially crucial. Additionally, the PCB's durability and dependability in harsh environments are ensured by the chemical resistance of FR4 epoxy board.

Besides, FR4 is known for its incredible electrical protection properties. It effectively stops current leakage and ensures that signals travel correctly between PCB components. This quality is essential for keeping up with the trustworthiness of electronic circuits and forestalling shortcircuits or electrical disappointments.

In conclusion, FR4 is preferred for PCBs due to its superior electrical insulation properties, dimensional stability, heat and chemical resistance, and robust mechanical strength. These qualities pursue FR4 an ideal decision for different electronic applications where dependability, solidness, and proficient electrical execution are fundamental.

What are the advantages of FR4 material?

The FR4 material offers various critical benefits, highlighting its status as a favored decision in the domain of PCB producing:

- Exceptional Mechanical Strength: The PCBs are able to effectively withstand the physical stress and vibrations encountered during operation and handling thanks to the FR4 epoxy material's incorporation of fiberglass reinforcement.

- Temperature Stability: The epoxy pitches present in FR4 display estimable warm properties, guaranteeing that the PCBs can dependably work across a wide temperature range without compromising execution or primary respectability.

- Magnificent Electrical Protection: FR4 stands apart as an exceptional electrical separator, really forestalling flow spillage and protecting the respectability of signs inside complicated electronic circuits, subsequently relieving the dangers of electrical glitches or disturbances.

- Cost-Effectiveness: FR4 exhibits relative cost-effectiveness in comparison to a number of other specialized PCB materials, making it suitable for consumer electronics production and mass production. Its widespread acceptance and adaptability to a wide range of electronic applications are facilitated by its affordability.

How does FR4 compare to other PCB materials?

Several distinctions can be observed when comparing FR4 to other PCB materials like PTFE (Polytetrafluoroethylene), highlighting the distinct characteristics of each material:

- Constant of Dielectricity: One eminent distinction lies in the dielectric steady. PTFE ordinarily has a lower dielectric steady contrasted with FR4. This trait can be worthwhile in high-recurrence applications where it is urgent to keep up with signal trustworthiness. The lower dielectric steady of PTFE considers better sign proliferation and decreased signal misfortune.

- Tangent of Loss: When compared to FR4, PTFE typically has a lower loss tangent, also known as the dissipation factor. The lower misfortune digression of PTFE adds to better high-recurrence execution by limiting energy misfortune as intensity. This trademark is especially significant in applications where signal precision and negligible twisting are vital.

- Conductivity of heat: Another separating factor is warm conductivity. FR4 Epoxy Board will in general have a lower warm conductivity contrasted with PTFE. This inconsistency influences the intensity dissemination abilities of PCBs. Because of its higher thermal conductivity, PTFE can transfer heat more effectively, making it suitable for applications requiring improved thermal management.

- Manufacturability: FR4 has some advantages over PTFE in terms of its manufacturability. FR4 is by and large simpler to fabricate and process because of its better bond properties. In contrast, adhesion issues with PTFE necessitate specialized methods for ensuring proper bonding between layers and components during the fabrication process.

Because they have a direct impact on the performance, dependability, and manufactureability of electronic devices, it is essential to take these aspects into consideration when selecting a PCB material. The decision among FR4 and PTFE, or some other material, eventually relies upon the particular prerequisites of the application being referred to.

Conclusion

All in all, while FR4 epoxy stays the go-to decision for some standard PCB applications because of its equilibrium of mechanical strength, electrical properties, and cost-viability, PTFE finds its specialty in high-recurrence and elite execution applications where prevalent electrical attributes are required. The two materials have their assets and are picked in light of explicit plan necessities, featuring the significance of choosing the right PCB material for ideal execution and dependability.

References

1. "FR-4 (FR4) Glass Epoxy Sheet Material | CTE-Laminate.com"

2. "FR4 PCB Material | What is FR-4? | 4pcb.com"

3. "Understanding FR-4 Material for PCB Design | Sierra Circuits"

4. "The Differences Between PTFE and FR4 PCB Materials | Epec Engineering"

5. "Why is FR-4 the Most Popular PCB Material? | Royal Circuits"

6. "PTFE PCB Substrates | Rogers Corporation"

7. "FR-4 PCB Materials | Waveroom Plus"

8. "PTFE vs FR4 PCB: Which Is Right for Your Project? | Omni PCB"

9. "PCB Material Selection Guide | PCBCart"

10. "Printed Circuit Board Materials | Electronic Design"