Is Bakelite Board Waterproof?

2024-07-23 15:23:50

Phenolic paper laminate, commonly referred to as bakelite board, is a strong and adaptable material that finds extensive usage in both consumer and industrial applications. Is Bakelite waterproof? is one of the most often asked questions concerning Bakelite boards. Determining its appropriateness for a given application requires an understanding of its water resistance characteristics. This blog will discuss how to improve Bakelite board's water resistance, how waterproof it is, and how it is used in damp conditions.

What Makes Bakelite Board Water-Resistant?

Due to its resistance to water, bakelite board is widely used in applications where dampness openness is a concern. We will discuss the processes and factors that contribute to the water resistance of Bakelite board in this section.

The structure of bakelite board is made up of the layers of paper or texture that have been coated with phenolic gum, which is a type of thermosetting plastic. The phenolic tar's ability to resist water is advantageous to the board. The structure becomes tough, long-lasting, and resistant to chemicals once the resin has dried. It can stand up to moisture without getting damaged.

The phenolic tar that makes up phenolic tar bakelite board significantly adds to its water obstruction. Phenolic resins are well-known for their high mechanical strength and resistance to chemicals. Ensuing to easing, they structure a polymer network with cross-joins, outlining a thick, water-safe obstacle. This network keeps the board's integrity even in wet conditions by preventing water molecules from entering.

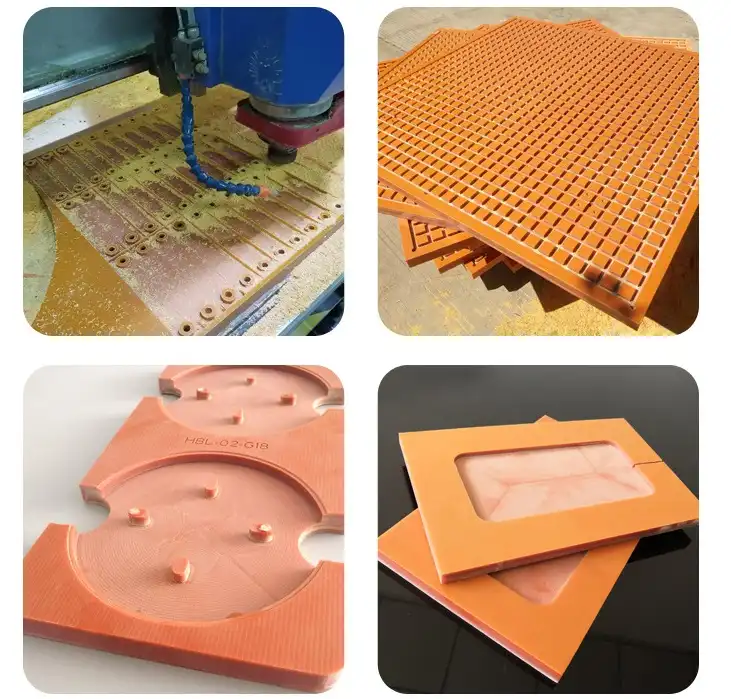

Covering Interaction The capacity of the product to endure water is likewise impacted by the assembling system. After being thoroughly coated with phenolic resin, the layers of paper or fabric are pressed and cured at a high temperature and pressure. You can be sure that the resin completely covers the fibers and forms a solid, cohesive structure that keeps water out if you follow this procedure.

Retention Pace of Water how much Bakelite board takes in water is a pivotal measurement for deciding its protection from water. This rate demonstrates the load up's capacity to hold water for a given amount of time. Due to its low water absorption rate—typically less than one percent—bakelite board maintains its mechanical and electrical properties when wet.

Solidness in Wet Conditions The strength of the product in wet conditions is one more delineation of its water-safe properties. It is suitable for applications where prolonged moisture exposure is anticipated because it does not swell, warp, or lose strength when exposed to water. The board is dependable because its stability ensures that it will keep its shape and function even in wet conditions.

How Is Bakelite Board Used in Moisture-Prone Applications?

Due to its resistance to water, bakelite board is utilized in numerous applications where moisture exposure is a concern. We'll look at some common uses for Bakelite board in moist environments and how its resistance to water makes these uses better in this section.

Electrical and Electronic Uses the product is frequently used as a protective material in electrical and electronic applications due to its excellent electrical protection and water resistance. It is used frequently:

Printed Circuit Sheets (PCBs) which serves as the base material for printed circuit sheets (PCBs) in conditions with acceptable dampness and openness. Due to its water resistance, the electrical components are protected from water-induced short circuits and kept insulated.

Electrical Panels and Switchboards which is frequently utilized as the backing material for electrical panels and switchboards. Its resistance to water prevents moisture from compromising the electrical connections and components contained within these boards, ensuring reliable operation.

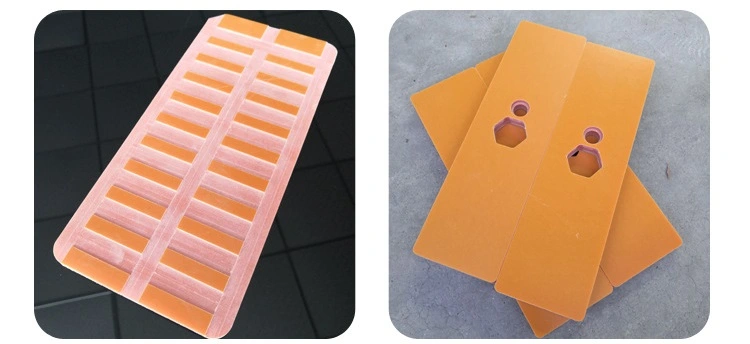

In industrial settings that are subjected to moisture, chemicals, and harsh environments, which is utilized for a variety of components. It is appropriate for: because of its strength and protection from water:

Machine Parts Bakelite-board parts like cog wheels, direction, and covers can endure dampness without losing their mechanical trustworthiness. This ensures the dependability and durability of machinery and equipment in wet conditions.

Industrial Equipment Covers and Shields Protective covers and shields are made of the product. These covers make the equipment last longer and require less maintenance because they protect delicate parts from chemicals, dust, and moisture.

Applications in the Marine and the Outdoors which is a great material for marine and outdoor applications where it is expected that there will be constant contact with water and the elements because of its resistance to water. It is used for:

which is used in the construction of boats and other marine vessels. It is a water-resistant material for bulkheads, partitions, and panels that lasts a long time. Due to its resistance to both salt and water, it is suitable for harsh marine environments.

Bakelite board can be used to build outdoor structures like benches, tables, and shelters. Outdoor furniture and structures These things can endure downpour, moistness, and other atmospheric conditions without crumbling in light of the fact that they are water safe.

Bakelite board is used in a variety of primary and beautiful applications in the construction industry where dampness obstruction is important. It is utilized:

Wall Panels and Partitions which is used to construct buildings' water-resistant wall panels and partitions. These panels are great for bathrooms, kitchens, and basements with high humidity because they don't absorb water and keep their structural integrity.

Formwork and Molds Bakelite board-based development formwork and molds are used in substantial projecting. Considering repeated use and consistent results, the board's water-safe properties ensure that it does not deteriorate or lose its shape when exposed to wet cement.

How Can the Water Resistance of Bakelite Board Be Enhanced?

While Bakelite board is inherently water-resistant, there are methods to further enhance its water resistance for specific applications. This section will discuss various techniques and treatments that can be applied to board to improve its performance in wet environments.

Surface Coatings

Applying surface coatings is one of the most effective ways to enhance the water resistance of board. These coatings create an additional protective layer that further prevents water ingress.

Epoxy Coatings

Epoxy coatings are commonly used to enhance the water resistance of board. These coatings form a hard, impermeable layer that provides excellent protection against moisture. Epoxy coatings are applied as a liquid and then cured to form a solid, durable surface.

Polyurethane Coatings

Polyurethane coatings offer similar benefits to epoxy coatings, providing a flexible and resilient protective layer. These coatings are resistant to abrasion, chemicals, and moisture, making them suitable for applications where additional water resistance is required.

Lamination

Laminating the product with additional layers of water-resistant materials can enhance its moisture protection. This method involves bonding a thin layer of a different material to the surface of the product.

Plastic Lamination

Plastic lamination involves bonding a thin plastic film to the surface of the product. This film provides an extra barrier against moisture, further protecting the board from water ingress. Plastic lamination is commonly used in applications where enhanced water resistance is critical.

Metal Foil Lamination

Metal foil lamination involves bonding a thin layer of metal, such as aluminum, to the product. The metal layer provides excellent water resistance and adds to the board's mechanical strength and durability. This method is used in applications requiring both moisture protection and enhanced structural integrity.

Sealing Edges and Joints

Sealing the edges and joints of board can prevent water from entering through these vulnerable areas. This technique is particularly important in applications where the board is exposed to direct water contact.

Silicone Sealants

Silicone sealants are commonly used to seal the edges and joints of the product. These sealants provide a waterproof barrier and remain flexible, accommodating any movement or expansion of the board. Silicone sealants are ideal for use in wet environments and areas exposed to frequent water contact.

Acrylic Sealants

Acrylic sealants offer similar benefits to silicone sealants, providing a waterproof and flexible barrier. They are easy to apply and can be used to seal joints and edges effectively. Acrylic sealants are suitable for both indoor and outdoor applications.

Impregnation Treatments

Impregnation treatments involve soaking the board in water-repellent chemicals to enhance its water resistance. These treatments penetrate the board's surface, providing long-lasting protection against moisture.

Waterproofing Solutions

Various waterproofing solutions can be used to impregnateboard. These solutions contain water-repellent chemicals that penetrate the board and create a barrier against moisture. Impregnation treatments are ideal for applications where enhanced water resistance is required over the long term.

Conclusion

Bakelite board, known for its durability, electrical insulation, and chemical resistance, also possesses significant water-resistant properties. Its composition, manufacturing process, and low water absorption rate make it suitable for various moisture-prone applications, including electrical and electronic uses, industrial components, marine and outdoor environments, and construction. While board is inherently water-resistant, additional techniques such as surface coatings, lamination, sealing, and impregnation treatments can further enhance its water resistance. Understanding these properties and methods ensures that board can be effectively used in applications where moisture exposure is a concern.

References

1. **"Phenolic Laminates - Characteristics and Applications," Professional Plastics.** Accessed at: https://www.professionalplastics.com/PhenolicLaminates

2. **"Bakelite - The First Synthetic Plastic," American Chemical Society.** Accessed at: https://www.acs.org/content/acs/en/education/whatischemistry/landmarks/bakelite.html

3. **"Mechanical Properties of Phenolic Laminates," ScienceDirect.** Accessed at: https://www.sciencedirect.com/topics/materials-science/phenolic-laminate

4. **"Water Resistance of Phenolic Laminates," MatWeb.** Accessed at: https://www.matweb.com/search/datasheet.aspx?matguid=12347