Epoxy Casting Resin

Basic Information:

Brand:Jinghong

Material:Epoxy Resin

Color: Transparent

Shelf Life:12 Months

Model Number: JQ-3

Payment Terms: L/C T/T Credit Card

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Production Description

Epoxy Casting Resin is a two component epoxy resin adhesive that requires high transparency, high hardness, high adhesion, and high resistance to yellowing. There are not many adhesives that can meet this condition. Additionally, the curing temperature of the resin needs to be stable to avoid the problem of adhesive explosion during summer operation, which is caused by rapid heat release and delamination and whitening of the gel and wood. Many adhesives on the market are ordinary resins that are not resistant to yellowing, which requires attention. Therefore, many people choose to add various colors, pearl powder, and color paste to make some designs to avoid the embarrassment caused by the yellowing of the gel.

There are two types three types of casting resin:

| Types | Weight Ratio | Viscosity of A | Viscosity of B | Operation Time | Final Curing Time | Initial Curing Time | ShoreD |

|

31 AB-7T |

3:1 | 800cps | 80cps | 2h | 36h | 8h | 83D |

| 31 AB-9T | 2:1 | 1000cps | 1000cps | 12h | 48h | 24h | 82D |

| 31 AB-9V | 2:1 | 1000cps | 200cps | 16h | 48h | 24h | 82D |

Single maximum pouring thickness:

-

31 AB-7T: 1-3CM

-

31 AB-9T: 8-12CM

-

31 AB-9V: 15-18CM

Data Sheet

|

Part |

31A-7T |

31B-7T |

|

Color |

Transparent |

Transparent |

|

Specific gravity |

1.15 |

0.96 |

|

Viscosity (25℃) |

2000-4000CPS |

80 MAXCPS |

|

Mixing ratio |

A: B = 100:33(weight ratio) |

A: B = 100:33(weight ratio) |

|

Hardening conditions |

25 ℃×8H to 10H or 55℃×1.5H (2 g) |

25 ℃×8H to 10H or 55℃×1.5H (2 g) |

|

Usable time |

25℃×40min (100g) |

25℃×40min (100g) |

|

Part |

31A-9T |

31B-9T |

|

Color |

Transparent |

Transparent |

|

Specific gravity |

1.15 |

0.97 |

|

Viscosity (25℃) |

2000-4000CPS |

50 MAXCPS |

|

Mixing ratio |

A: B = 100:50(weight ratio) |

A: B = 100:50(weight ratio) |

|

Hardening conditions |

25 ℃ × 48H - 72H |

25 ℃ × 48H - 72H |

|

Usable time |

25 ℃ × 30min (100g) |

25 ℃ × 30min (100g) |

|

item |

value |

|

CAS No. |

38891-59-7 |

|

Other Names |

epoxy resin ab glue |

|

MF |

C15H16O2C2H7ONC3H5OCl |

|

EINECS No. |

231-072-3 |

|

Place of Origin |

China |

|

Classification |

Double Components Adhesives |

|

Main Raw Material |

Epoxy |

|

Usage |

Fiber & Garment, Packing, Woodworking |

|

Brand Name |

Jinghong |

|

Model Number |

318AB-9T |

|

Type |

liquid glue |

|

Viscosity |

A=2000-4000CPS, B=50MAXCPS |

|

Shelf life |

6 Months |

|

Color |

Clear |

|

Certificate |

ROHS, REACH, PAHS, ASTM, EN-71 |

|

Mixing Ratio |

A:B=2:1 |

|

Packing |

Bottle |

Application and Feature

Epoxy Casting Resin is specially designed for large size wood table casting, lamp potting and mold filling, etc.. and can be cured under normal temperature and high temperature, with the feature of good flowing property, low viscosity, very little heat release, natural defoaming, anti-yellow, high transparency, no ripple, bright in surface.

Storage

1. Store in a cool and dry place for a storage period of 12 months (at 25 ℃).

2. This type of product belongs to non hazardous goods and can be transported as general chemicals.

3. Both components A and B of the colloid must be sealed and stored to prevent leakage during transportation!

4. Products that have exceeded their shelf life should be confirmed for any abnormalities before use.

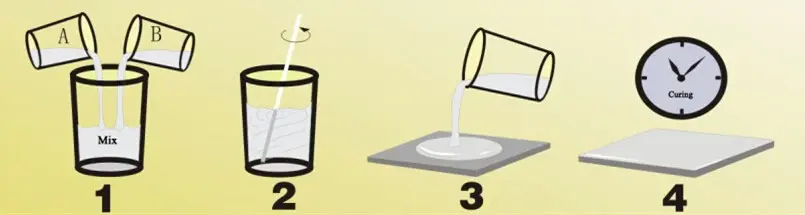

Operation

1.Weigh A and B glue according to the given weight ratio into the prepared cleaned container, fully mixed the mixture again the container wall by clockwise, place it along for 3 to 5 minutes, and then it can be used.

2.Take the glue according to the usable time and dosage of mixture to avoid wasting. When the temperature is below 15 ℃, please heat A glue to 30 ℃ first and then mix it to the B glue (A glue will be thicken in low temperature ); The glue must be sealed lid after use to avoid rejection caused by moisture absorption.

3.When the relative humidity is higher than 85%, the surface of the cured mixture will absorb moisture in the air, and form a layer of white mist in the surface, so when the relative humidity is higher than 85%, is not suitable for room temperature curing,suggest to use the heat curing.

Announcement

1. Instruments such as scales (or electronic scales), ovens, workbenches, or work carriers must be placed horizontally, otherwise it may affect the accuracy of weighing or cause the work object that has just dropped glue to overflow.

When using a balance or electronic scale to weigh the glue, it is necessary to remove the weight of the container to avoid inaccurate weighing.

3. The containers used must be dry, clean, and dust-free, otherwise it will affect the surface effect of the adhesive after solidification, leading to adverse phenomena such as ripples, water marks, and pits.

4. The glue must be accurately weighed according to the weight ratio, as an imbalance in the ratio can cause the glue to not dry for a long time or the hard glue to become soft.

5. The adhesive must be stirred evenly, otherwise the surface of the adhesive will have turtle shell or resin lines after curing, or the adhesive will not cure completely.

6. The operating site and working environment must be well ventilated and must be free of dust and debris, otherwise it may affect the transparency of the gel or cause spots or effects on the surface of the adhesive after solidification.

7. It is recommended to control the relative humidity of the working environment within 68%, and the on-site temperature should be between 23 and 25 ℃. If the working environment is too humid, the surface of the adhesive will be oxidized into mist or bubbles that are difficult to dissipate. Low or high temperatures can affect the curing and usage time of the adhesive.

8. The operation objects dripping glue should be dried in the concentrated area, and the drying temperature should be controlled at about 28 ℃ -40 ℃.

9. If the delivery time is tight, heating and curing can be used, but the heating must be done in a concentrated drying area for more than 90 minutes. The heating temperature should be controlled within 65 ℃, and the specific drying time should be determined based on the adhesive itself. Our company's flat soft or hard adhesive can fully cure in 2 hours at a temperature of 60 ℃ If it is not urgent for the delivery time, please try to use room temperature curing at 28-35 ℃, which should take about 20 hours to ensure the quality of the adhesive to the maximum extent.

10. After opening the lid of the glue bucket and pouring out the glue, it is necessary to cover it immediately to avoid prolonged contact with air that may cause the glue to oxidize and crystallize.

Factory Equipment

Hebei Linyuan Fine Chemical Co., Ltd. was established in January 2017, and it was funded and constructed by Hebei JingHong Electronic Technology Co., Ltd and its subsidiary Hongda Insulation Material Factory which specialize in the production of 3240 Epoxy Resin Board, FR4 Fiberglass Sheet, Phenolic Cotton Cloth Laminate Sheet 3026, phenolic paper board and copper clad laminate.

JingHong had a factory before in Xiong'an New District, Hebei, which produced E44 epoxy resin only. The production volume was small and part of it was used for its own. Therefore, there was not much sales in the market. Due to the wide applications of epoxy resin, China has become the world's largest producer and consumer of epoxy resins. In order to comply with the market trend, the company combined the company's own situation, withdrew from Xiong'an New Area, and built an epoxy resin factory with an annual output of 20,000 tons in Cangzhou. The project has been completed and put into production.

The project is designed with reference of Japan’s Toto Kasei technology. The current production of epoxy resins include E44, E51, etc., and varieties will be gradually added according to market demand in the future. The person who take in charge of the company said: At present, the epoxy resin production capacity is 20,000 tons. According to the actual market situation, the production capacity is going to expand to 100,000 tons.

Packaging and Shipping

Send Inquiry