What are the applications of Epoxy Resin Sheets?

2024-07-11 17:23:29

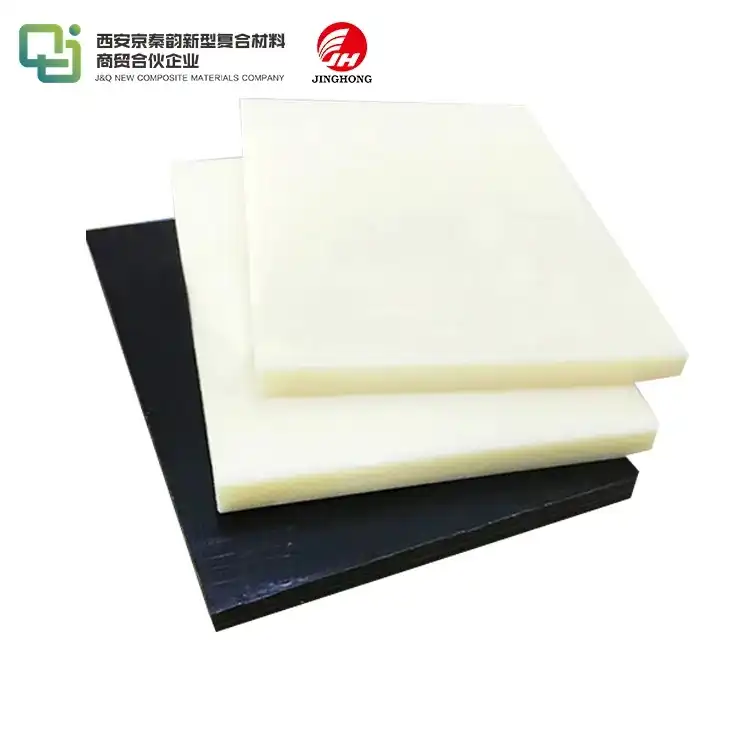

Introduction to Epoxy Resin Sheets

Epoxy resin sheets, also known as fiberglass reinforced plastic (FRP) sheets, are composite materials made from epoxy resin and fiberglass reinforcement. These sheets are renowned for their exceptional strength, durability, and versatility. The product are widely used across various industries due to their excellent chemical resistance, electrical insulation properties, and mechanical strength. In this article, we will explore the diverse applications of the product and their significance in different fields.

Electrical Applications

One of the primary applications of FR4 Glass Epoxy Sheet is in electrical engineering. These sheets are commonly used as insulating materials in electrical equipment and components. The product provide excellent electrical insulation, making them ideal for applications where electrical conductivity must be avoided or minimized. They are frequently used in the manufacturing of electrical panels, transformers, circuit boards, and insulating bushings. Epoxy resin sheets offer high dielectric strength, ensuring reliable performance and safety in electrical systems.

Construction and Architecture

In the development and engineering industry, the products track down far and wide use because of their underlying strength and sturdiness. These sheets are used for different applications like cladding, material, and façade frameworks. The product offer prevalent climate opposition, UV dependability, and erosion obstruction, making them appropriate for both inside and outside applications. They can be formed into various shapes and sizes, permitting modelers and originators to make inventive and outwardly engaging designs.

Automotive and Transportation

Epoxy Resin Sheet assume a critical part in the car and transportation area, where lightweight and superior execution materials are popular. These sheets are utilized in the assembling of vehicle parts, including body boards, inside trim, and underlying fortifications. The product offer extraordinary solidarity to-weight proportion, influence opposition, and layered soundness, making them ideal for improving the exhibition and productivity of vehicles. Also, their capacity to endure unforgiving ecological circumstances makes them reasonable for marine and aviation applications.

Industrial and Manufacturing

In the industrial and manufacturing sector, Epoxy resin sheets are valued for their mechanical properties and chemical resistance. These sheets are commonly employed in industrial equipment, machinery, and tooling applications. The product serve as protective barriers against abrasion, corrosion, and chemical exposure, prolonging the lifespan of industrial assets. They are also used for fabricating tanks, pipes, and ductwork in chemical processing plants, wastewater treatment facilities, and other industrial settings.

Composite Materials:

Epoxy Resin Sheets are ordinarily utilized as lattice materials in the manufacture of composite materials, for example, fiberglass supported plastics (FRP) and carbon fiber built up plastics (CFRP).

By impregnating building up filaments, like glass strands or carbon filaments, with epoxy sap and restoring them under intensity and strain, composite materials with predominant mechanical properties, like strength, firmness, and effect obstruction, can be delivered for applications in aviation, car, outdoor supplies, and framework.

Defensive Coatings and Glues:

Epoxy Resin Sheets are used as coatings and cements for different substrates, including metals, cement, wood, and plastics.

The product give a defensive obstruction against erosion, scraped spot, and compound openness, making them reasonable for use in modern offices, marine designs, car parts, and customer products.

The product offer high strength and holding execution, making them ideal for holding primary parts, covering materials, and fixing surfaces in development, assembling, and support applications.

Tooling and Forms:

The product are utilized to make tooling and shape for assembling processes, for example, composite manufacture, infusion trim, and vacuum framing.

Epoxy gum tooling sheets and shape offer layered dependability, warm obstruction, and surface completion quality, considering the creation of exact and complex parts in ventures like aviation, car, marine, and wind energy.

Workmanship and Plan:

Epoxy Resin Sheets are famous materials in craftsmanship and plan for making models, furniture, gems, and beautifying objects.

The unmistakable, reflexive completion of the product, joined with their capacity to be pigmented, colored, and implanted with different materials, offers specialists and creators interminable innovative opportunities for communicating their vision and making one of a kind, outwardly dazzling pieces.

Deck and Ledges:

FR4 Glass Epoxy Sheets are utilized as coatings and overlays for deck and ledges in private, business, and modern settings.

The product offers strength, substance obstruction, and embellishing bid, making it reasonable for applications, for example, carport floors, business kitchens, and modern stockrooms.

The product give a consistent, non-permeable surface that is not difficult to clean and keep up with, making them ideal for use in labs, cafés, and medical services offices.

Gadgets Exemplification:

The product are utilized for epitomizing and preparing electronic parts to safeguard them from dampness, residue, vibration, and warm cycling.

The product give fantastic bond, warm conductivity, and electrical protection properties, guaranteeing the dependability and life span of electronic gadgets in cruel working conditions, for example, car, aviation, and modern applications.

Sustainable power:

The product assume a significant part in the environmentally friendly power area for assembling parts like breeze turbine cutting edges, sunlight based chargers, and energy stockpiling frameworks.

The lightweight, sturdy, and consumption safe properties of the product make them appropriate for use in environmentally friendly power applications, where unwavering quality, proficiency, and life span are fundamental for supportable energy creation and capacity.

Conclusion

In conclusion, Epoxy resin sheets offer a myriad of applications across various industries, thanks to their exceptional properties and performance characteristics. From electrical insulation to architectural cladding, automotive components to industrial equipment, the product play a vital role in enhancing product performance, durability, and reliability. As technology advances and new formulations are developed, the applications of the product are expected to expand further, driving innovation and progress in numerous fields.

Contact us:Are you looking for high-quality the product for your next project? Look no further! We are a professional manufacturing supplier with a GMP factory, large inventory, and complete certificates. We support OEM orders, offer fast delivery, and ensure tight packaging to protect your products during transit. Contact us today at info@jhd-material.com to discuss your requirements and explore how we can support your business.

References

"Epoxy Resin Market Size, Share & Trends Analysis Report by Application (Paints & Coatings, Adhesives & Sealants, Composites), by End-use (Construction, Electrical & Electronics), by Region, and Segment Forecasts, 2020 - 2027." Grand View Research. Available at: https://www.grandviewresearch.com/industry-analysis/epoxy-resin-market

"Fiberglass Reinforced Plastic (FRP) Sheets Market Size, Share & Trends Analysis Report by Resin Type (Polyester, Vinyl Ester, Epoxy), by Application (Building & Construction, Automotive, Aerospace & Defense), by Region, and Segment Forecasts, 2020 - 2027." Grand View Research. Available at: https://www.grandviewresearch.com/industry-analysis/fiberglass-reinforced-plastic-frp-sheets-market