Precautions for Use and Assembly of Polymer Lithium Battery Cells

2022-06-27

Polymer battery is also a kind of lithium-ion battery, but compared with liquid lithium ion battery (Li ion), it has many obvious advantages, such as high energy density, miniaturization, ultra-thin, lightweight, high security and so on. It is a new type of battery. In terms of shape, lithium polymer batteries have ultra-thin characteristics, and can be made into batteries of any shape and capacity to meet the needs of various products.

Polymer battery is a kind of lithium battery with gel electrolyte and flexible packaging. It is often called soft packed lithium battery in the civil market, which makes the lithium battery cell different from the ordinary liquid lithium-ion battery. Therefore, there are some special precautions. The following precautions are put forward for the possible incorrect practices during the use and assembly of the cell.

In terms of the use of electric cores, it includes the protection of aluminum-plastic composite film, top edge sealing (edge sealing at the end of the pole handle), side edge sealing, pole handle and measures to avoid mechanical impact and short circuit.

1. Aluminum plastic composite film outer packaging protection: mainly to avoid being damaged by sharp parts. For this reason, the surrounding environment of the battery should be cleaned from time to time. Sharp parts are not allowed to contact or collide with the battery cell. Gloves can be worn when taking it to avoid scratching the surface of the battery cell with fingernails.

2. Top and side edge sealing protection: in order to avoid damage to the top and side edges and damage the sealing effect, it is forbidden to bend the top and side edges; At the same time, reliable insulation and isolation measures must be taken in the design of the electric core to avoid the short circuit between the negative electrode and the aluminum-plastic composite film.

3. Pole handle protection: aluminum pole handle is used as the positive pole outgoing terminal of polymer lithium battery cell, and nickel pole handle is used as the negative pole outgoing terminal. As the pole handle is thin, bending shall be prohibited; At the same time, avoid the contact between the pole handle and the aluminum-plastic composite film during the production process, and strictly isolate it with the ferrule film.

4. Avoid mechanical impact, such as falling, striking, bending the cell and accidentally stepping on the battery.

5. It is forbidden to use metal objects or wires to short circuit the positive and negative electrodes.

After a cell is completed, the next step is to correctly combine it with the shell and the cell protection circuit module to make it a polymer battery. The precautions in this process include:

1. Housing design:

(1) Sufficient mechanical strength to avoid external mechanical damage to the cell,

(2) When the electric cell is installed in the shell, avoid the sharp edges and corners of the shell scratching the electric cell;

(3) Prevent the aluminum-plastic composite film sandwich pure aluminum from short circuit due to external contact.

2. Cell protection circuit must be designed: including scientific setting of maximum / minimum voltage, overcurrent protection, and overcharge and discharge protection for battery unit (single cell) for combined use of cells.

3. The transfer of positive aluminum electrode handle through nickel strip and the connection between electric core and circuit board shall be implemented by ultrasonic welding or spot welding technology.

4. Reliable positioning of the battery cell. After assembly, the battery cell shall be firmly fastened in the shell and will not move, so that the whole lithium battery structure is in a consolidated state.

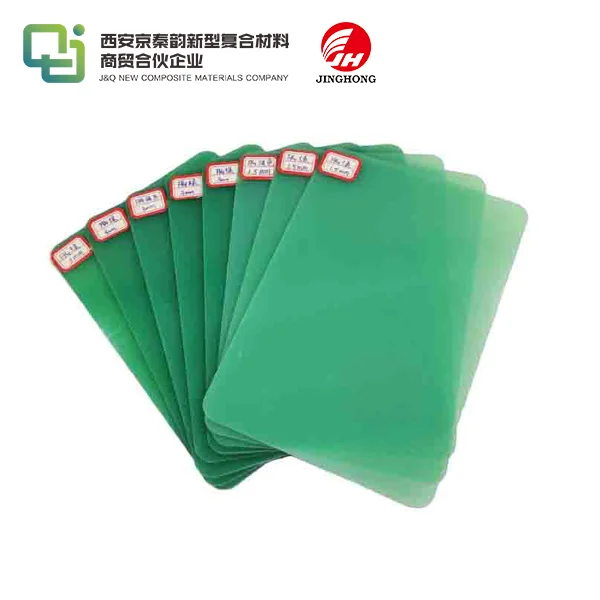

5. the battery box shall be separated from the battery with 3240 epoxy sheet to prevent short circuit and leakage. If you are afraid of shaking, you can use pearl foam (the kind you bring in your computer box) to prevent earthquakes.

|

6. for waterproof, the outlet and handle of the box are sealed with 704 silicone rubber.