Is a Flame Resistance FR4 Fiber Glass Laminate Sheet suitable for marine environments?

2024-06-07 16:46:38

1. Understanding FR4 Fiber Glass Laminate Sheets

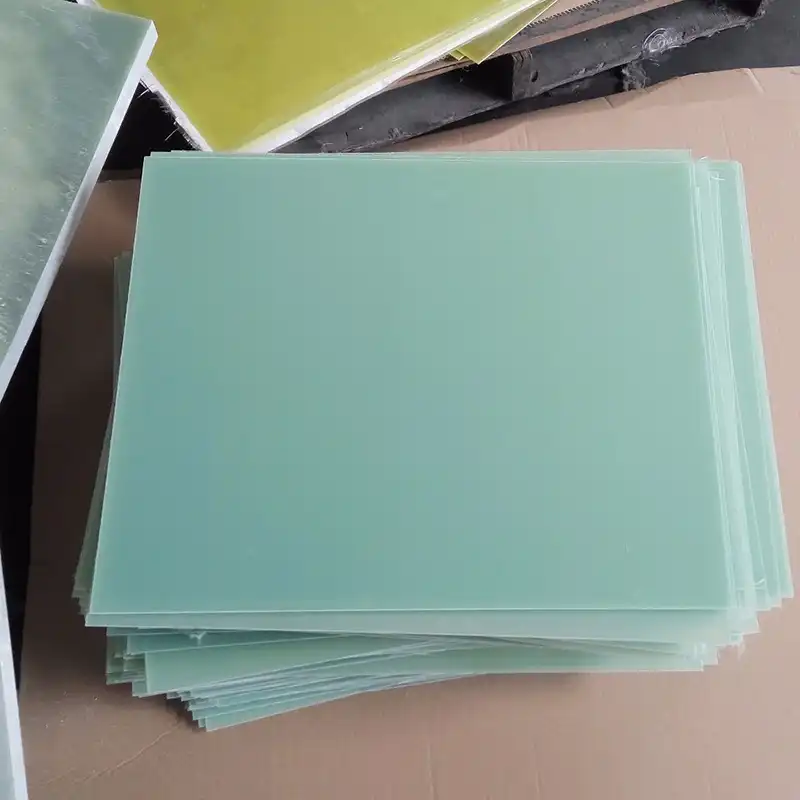

FR4 Fiber Glass Laminate Sheets are widely used in various industries due to their excellent electrical, mechanical, and thermal properties. These sheets are composed of a woven glass fabric combined with an epoxy resin binder, making them highly durable and resistant to heat and chemicals. The term "FR4" refers to the grade of the material, indicating its flame resistance. These sheets are commonly used in electrical applications such as printed circuit boards (PCBs), but their versatility extends to other fields as well, including marine environments.

2. The Importance of Flame Resistance in Marine Environments

Marine environments present unique challenges due to exposure to saltwater, humidity, and fluctuating temperatures. In such harsh conditions, materials used in marine applications must meet stringent requirements for durability and safety. Flame resistance is particularly crucial as it reduces the risk of fire onboard vessels, which can have catastrophic consequences. Therefore, selecting materials with adequate flame resistance, such as Flame Resistance FR4 Fiber Glass Laminate Sheet, is essential for ensuring the safety and reliability of marine equipment and structures.

3. Properties of FR4 Fiber Glass Laminate Sheets Relevant to Marine Environments

Flame Resistance FR4 Fiber Glass Laminate Sheets have a few properties that make them well-suited for marine situations. Firstly, their fabulous electrical cover properties make them perfect for utilize in electrical frameworks onboard ships and seaward stages. Also, their tall mechanical quality and dimensional solidness guarantee they can withstand the rigors of marine applications, counting introduction to vibrations and impacts. Moreover, their resistance to erosion and dampness entrance upgrades their life span in saltwater situations, where routine materials may break down rapidly.

4. Applications of FR4 Fiber Glass Cover Sheets in Marine Engineering

In marine designing, Flame Resistance FR4 Fiber Glass Laminate Sheets discover different applications over different components and frameworks. One common application is in the creation of PCBs for marine gadgets and communication frameworks. The fire resistance of FR4 guarantees the security and unwavering quality of these basic components, anticipating electrical fires that seem compromise route and communication onboard vessels. Also, FR4 sheets are utilized in the development of auxiliary components such as bulkheads, boards, and walled in areas, where their combination of quality and fire resistance is profoundly advantageous.

Another critical application of FR4 fiber glass cover sheets in marine designing is in the advancement of lightweight, high-strength composite materials for pontoon frames and decks. The material's great mechanical properties empower the creation of strong however lightweight structures that make strides fuel productivity and execution without compromising security. The erosion resistance of FR4 moreover makes it appropriate for utilize in marine situations where presentation to saltwater and other chemicals is common, guaranteeing life span and diminishing upkeep necessities.

Besides, FR4's warm solidness and electrical separator properties make it a favored fabric for different electrical components in marine vessels. These incorporate insulin, bushings, and terminal sheets, which must withstand the cruel marine environment whereas keeping up their usefulness. By utilizing FR4 in these applications, engineers can improve the by and large security and unwavering quality of the vessel's electrical frameworks, securing against brief circuits and other potential hazards.

In rundown, Flame Resistance FR4 Fiber Glass Laminate Sheets play a significant part in marine building due to their one of a kind combination of fire resistance, quality, strength, and natural versatility. Whether utilized in gadgets, auxiliary components, or specialized electrical applications, FR4 contributes to the security, productivity, and execution of marine vessels, making it an basic fabric in the progression of marine technology.

5. Contemplations for Selecting FR4 Fiber Glass Cover Sheets for Marine Applications

When choosing Flame Resistance FR4 Fiber Glass Laminate Sheets for marine applications, a few components ought to be taken into account to guarantee ideal execution and compatibility with the marine environment. Firstly, the fabric ought to meet pertinent industry benchmarks and certifications for marine utilize, such as those set forward by classification social orders like DNV, ABS, or Lloyds Enroll. Furthermore, the particular prerequisites of the application, counting temperature run, presentation to chemicals, and mechanical loads, ought to be carefully considered to select the suitable review and thickness of FR4 sheet. Counseling with experienced engineers and providers can offer assistance guarantee the right fabric determination for the planning marine application.

Contact Us

For professional manufacturing and supply of high-quality FR4 Fiber Glass Laminate Sheets, contact us at info@jhd-material.com. We are a GMP factory with a large inventory and complete certificates to meet your marine engineering needs. Our OEM support, fast delivery, and tight packaging ensure a seamless procurement process. Partner with us and benefit from our expertise in providing reliable solutions for marine applications.

References

1. IPC-4101B/41C: Specification for Base Materials for Rigid and Multilayer Printed Boards

2. ASTM D6262: Standard Specification for Extruded, Compression Molded, and Injection Molded Basic Shapes of Polyimide (PI)

3. DNV Rules for Classification of Ships, Part 4: Electrical Installations

4. ABS Rules for Building and Classing Steel Vessels Under 90 Meters (295 Feet) in Length

5. Lloyds Register Rules and Regulations for the Classification of Ships