How do you cut an Epoxy Resin Sheet?

2024-05-10 14:41:06

Cutting epoxy resin sheets can seem daunting, but with the right tools and techniques, you can achieve clean and precise cuts. Below, I'll guide you through several methods and key tips for handling epoxy resin effectively.

Essential Tools and Preparation

Cutting epoxy sheets demands precision, proper tools, and meticulous preparation to achieve clean, accurate cuts without compromising material integrity. Whether for shaping custom components, fabricating electrical insulation, or crafting intricate designs, mastering the art of cutting resin sheets is indispensable. This guide elucidates the essential tools and preparatory steps required to execute flawless cuts on resin sheets.

Essential Tools

- Circular Saw or Jigsaw: Equipped with a fine-toothed carbide blade suitable for cutting dense materials, a circular saw or jigsaw serves as the primary cutting tool for resin sheets. Opt for blades specifically designed for cutting plastics or composite materials to minimize chipping and ensure smooth, precise cuts.

- Router: A router outfitted with a carbide-tipped cutting bit enables intricate profiling and edge finishing on resin sheets. This versatile tool facilitates beveling, chamfering, and decorative edge treatments, enhancing the aesthetic appeal and functional versatility of fabricated components.

- Utility Knife or Box Cutter: For scoring and scribing straight lines on resin sheets, a sharp utility knife or box cutter proves invaluable. These handheld cutting implements are ideal for making initial incisions, guiding subsequent cuts, and executing intricate detail work with precision and control.

- Straight Edge Guide: Employ a straight edge guide, such as a metal ruler or straightedge clamp, to ensure straight, uniform cuts along designated cutting lines. This guide serves as a reference for guiding cutting tools, minimizing deviation and optimizing cutting accuracy.

- Safety Equipment: Prioritize safety by donning personal protective equipment, including safety glasses, gloves, and a dust mask, to mitigate hazards associated with cutting resin sheets. Additionally, ensure adequate ventilation in the workspace to dissipate dust and fumes generated during cutting operations.

Preparation Steps

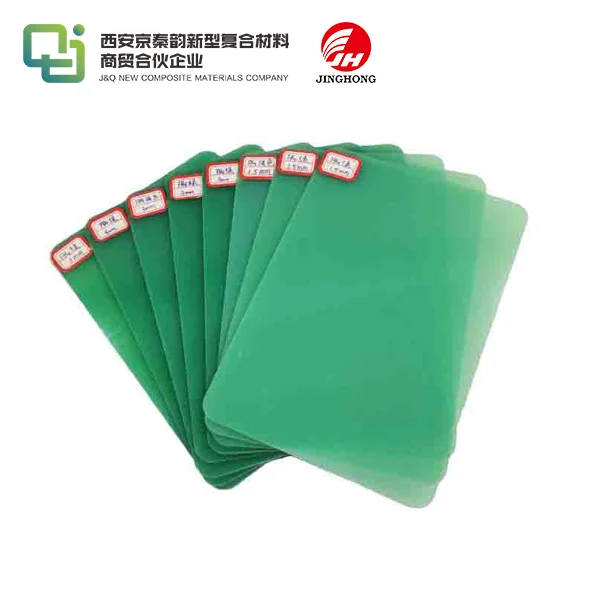

- Material Selection: Choose resin sheets of appropriate thickness and composition tailored to the intended application and cutting requirements. Verify that the selected material exhibits uniform density, minimal surface imperfections, and compatibility with cutting tools and techniques.

- Marking and Layout: Use a pencil or marker to delineate cutting lines and desired dimensions directly onto the surface of the epoxy resin sheet. Employ a measuring tape, square, or combination square to ensure precise measurements and accurate layout alignment.

- Secure Workpiece: Secure the epoxy resin sheets firmly in place on a stable work surface using clamps or adhesive-backed non-slip mats to prevent shifting or vibration during cutting operations. Maintain adequate support beneath the workpiece to minimize deflection and ensure clean, uniform cuts.

- Tool Setup and Calibration: Install the appropriate cutting blade or bit onto the selected cutting tool and adjust cutting depth, speed, and feed rate settings to suit the specific characteristics of the epoxy resin sheet. Perform test cuts on scrap material to fine-tune tool settings and verify cutting performance before proceeding with the final cuts.

- Dust Control Measures: Implement effective dust control measures, such as using a dust collection system or positioning a vacuum nozzle adjacent to the cutting area, to capture and remove airborne particulates and debris generated during cutting. Minimize dust accumulation on cutting tools and work surfaces to maintain cutting accuracy and prolong tool lifespan.

By adhering to these essential tools and preparatory steps, you can confidently undertake the task of cutting resin sheets with precision, efficiency, and safety. Mastery of cutting techniques coupled with proper equipment selection and meticulous preparation ensures optimal results, enabling you to realize your fabrication aspirations with finesse and proficiency.

Cutting Techniques:Using a Circular Saw or Table Saw

For straight, clean cuts, a circular saw or table saw is ideal. Set the blade to match the thickness of your resin sheet, mark your cut lines with masking tape to protect the resin from chipping, and proceed with the cut, ensuring a steady hand and even pressure throughout (Wood Fixes) (Tools Advisor).

Dremel Tool for Detailed Cuts

A Dremel tool, equipped with a cutting wheel, is perfect for more intricate work or if you need to make smaller, precise cuts. The key here is to operate at a steady pace to avoid cracks and to let the tool do the work without applying too much pressure (eHow UK).

Heat Cutting

For thinner resin sheets, you can also use heat to make the cutting process easier. By gently heating the line where you need to cut, the resin becomes more pliable. This method is particularly useful when using simpler tools like a multi-snip tool, which functions similarly to scissors (eHow UK).

Finishing Your Cut

After cutting, it's likely you'll have some rough edges. These can be smoothed with sandpaper, starting with a coarse grit and moving to a finer grit to achieve a smooth finish. If needed, a router can be used to create beveled edges for a more polished look (Wood Fixes).

Safety and Cleanup

Safety cannot be overstressed when working with epoxy resin. Wear protective gear such as safety glasses, gloves, and a respirator mask. Keep your workspace ventilated and clean up all tools and surfaces after cutting to avoid resin buildup, which can be hard to remove once cured (Wood Fixes) (ScienceSphere.blog).

Conclusion

Cutting epoxy resin doesn't have to be intimidating. With the proper setup, correct tools, and a careful approach, you can achieve professional results. Whether you're a seasoned crafter or a beginner, these tips will help you handle epoxy resin with confidence and safety.

Remember, if your project requires precision beyond what manual cutting can achieve, or if you're new to working with epoxy resin sheets, seeking professional help can ensure the best outcomes and is always a safe choice. As a professional manufacturer and supplier, we provide GMP factory conditions, large inventory, full certification, and OEM support with quick delivery and secure packaging. We encourage you to contact us for further assistance and to ensure high-quality results for your projects.