How do you install a Flame Resistance FR4 Fiber Glass Laminate Sheet?

2024-06-13 15:22:03

As a specialist in the field, I understand the importance of properly installing flame-resistant FR4 fiber glass laminate sheets. These sheets are commonly used in electrical and electronic applications due to their high heat resistance and insulation properties. In this comprehensive guide, I will walk you through the step-by-step process of installing Flame Resistance FR4 Fiber Glass Laminate Sheets safely and effectively.

1. Understanding FR4 Fiber Glass Laminate Sheets

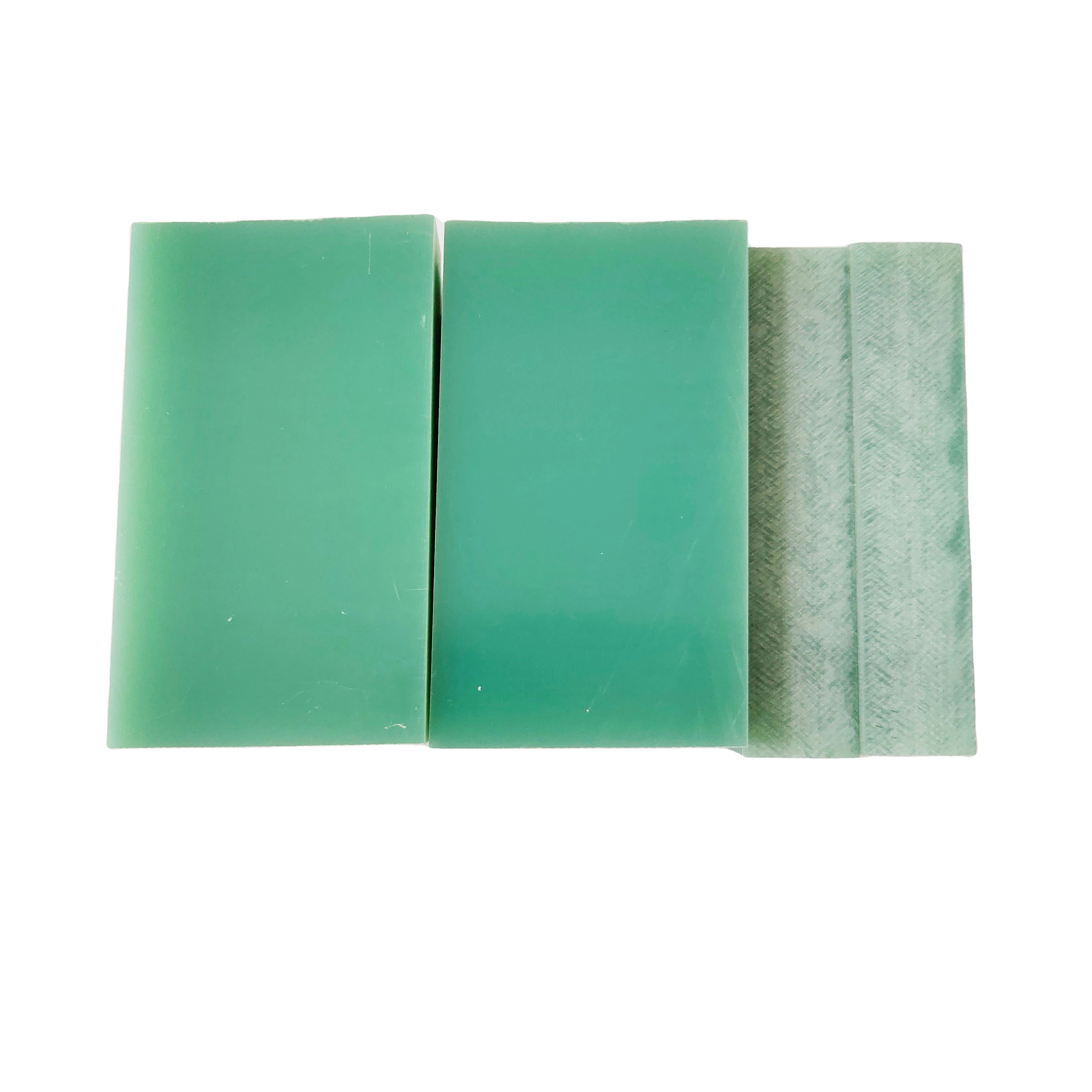

Before diving into the installation process, it's crucial to have a solid understanding of what Flame Resistance FR4 Fiber Glass Laminate Sheets are and why they are used. FR4 is a grade designation for flame-resistant fiberglass reinforced epoxy laminate. It is widely used in the manufacturing of printed circuit boards (PCBs) and electrical insulation due to its excellent electrical, thermal, and mechanical properties. These sheets are composed of woven fiberglass cloth impregnated with epoxy resin, making them highly resistant to heat and flame.

2. Preparing for Installation

Appropriate arrangement is key to a fruitful establishment. Start by guaranteeing that the work zone is clean, dry, and free from any flotsam and jetsam or contaminants. Assemble all the essential instruments and materials, counting the FR4 fiber glass cover sheets, defensive adapt such as gloves and security goggles, a cutting device, cement (on the off chance that required), and any extra back structures or fixtures.

3. Measuring and Cutting the Sheets

Next, carefully degree the zone where the Flame Resistance FR4 Fiber Glass Laminate Sheets will be introduced. Utilize a sharp cutting apparatus, such as a utility cut or a circular saw prepared with a fine-toothed edge, to cut the sheets to the required measurements. It's fundamental to make exact cuts to guarantee a legitimate fit and finish.

When cutting FR4 fiber glass cover sheets, it is too critical to utilize a straight edge or direct to keep up precision and maintain a strategic distance from uneven edges. This is especially pivotal when cutting huge pieces or making different indistinguishable cuts. A clamping framework can be utilized to secure the sheet in put amid cutting, anticipating development that may result in loose cuts.

Additionally, tidy and flotsam and jetsam created amid the cutting prepare ought to be carefully collected and arranged of legitimately. FR4 fiber glass cover can deliver fine particles that may be destructive if breathed in, so it's critical to wear suitable individual defensive hardware (PPE), such as veils and security goggles, amid the cutting operation. Ventilation ought to be satisfactory to guarantee the work environment remains secure and healthy.

In outline, measuring and cutting FR4 fiber glass cover sheets require exactness and caution to accomplish the craved measurements and guarantee a secure working environment. Legitimate instruments, strategies, and defensive measures are fundamental for effective integration of FR4 into any venture.

4. Applying Adhesive (if applicable)

In a few cases, cement may be required to secure the Flame Resistance FR4 Fiber Glass Laminate Sheets to the substrate. If cement is required, take after the manufacturer's enlightening carefully. Apply the cement equally to the substrate utilizing a appropriate implement, at that point carefully put the sheets onto the cement, guaranteeing appropriate arrangement and positioning.

When applying cement to the substrate some time recently putting FR4 fiber glass cover sheets, it is critical to consider the sort of cement and its compatibility with both the FR4 fabric and the substrate. A few cements may not bond well with certain materials, so choosing the right item is pivotal for guaranteeing a solid and tough association. It's moreover basic to permit adequate time for the cement to remedy completely agreeing to the manufacturer's determinations, as this will decide the quality and solidness of the bond.

Furthermore, after putting the FR4 sheets onto the cement, it's prescribed to utilize clamps or other obsession gadgets to hold the sheets in put until the cement has cured totally. This guarantees that the sheets do not move amid the holding handle, which may compromise the keenness of the establishment. Any overabundance cement that crushes out from the joint ought to be cleaned absent instantly to keep up a slick appearance and avoid potential harm to other components or surfaces.

In outline, when cement is required for introducing FR4 fiber glass cover sheets, cautious choice of the cement and consideration to legitimate application methods are basic for accomplishing a secure and stylishly satisfying result. Taking after the manufacturer's enlightening and taking fitting measures to guarantee the sheets stay legitimately adjusted amid the curing prepare will offer assistance ensure the victory of the establishment.

5. Securing and Finishing the Installation

Once the Flame Resistance FR4 Fiber Glass Laminate Sheets are in place, securely fasten them to the substrate using appropriate fasteners or clamps. Take care to evenly distribute pressure to prevent warping or distortion of the sheets. Finally, inspect the installation carefully to ensure that everything is securely in place and that there are no gaps or defects.

In conclusion, installing flame-resistant FR4 fiber glass laminate sheets requires careful planning, precise execution, and adherence to safety protocols. By following the steps outlined in this guide, you can ensure a successful installation that provides reliable protection and performance in electrical and electronic applications.

Contact us

Looking for a reliable supplier of Flame Resistance FR4 Fiber Glass Laminate Sheets? Look no further! We are a professional manufacturing supplier with a GMP factory, large inventory, and complete certificates. We support OEM orders and offer fast delivery with tight packaging to ensure product integrity. Contact us today at info@jhd-material.com to learn more and start a partnership that delivers quality and reliability.

References:

1. "Flame Resistant FR4 Fiber Glass Laminate Material Safety Data Sheet", Manufacturer XYZ.

2. "Installation Guide for FR4 Fiber Glass Laminate Sheets", Electrical Engineering Association.

3. "Properties and Applications of FR4 Fiber Glass Laminate", Journal of Materials Science.

4. "Best Practices for Handling and Installing FR4 Fiber Glass Laminate", International Standards Organization (ISO).

5. "FR4 Laminate Specifications and Standards", Institute of Electrical and Electronics Engineers (IEEE).