How do Epoxy Resin Sheets compare to other materials?

2024-07-29 14:12:38

Introduction

The adaptability, toughness, and far reaching utilizations of Epoxy Resin Sheets have filled their developing ubiquity across assorted businesses. By the by, while assessing materials for specific undertakings, it's urgent to compare epoxy sap sheets with other accessible choices. Inside this exhaustive aide, I mean to completely examine the correlation between epoxy gum sheets and elective materials, digging into their particular highlights, benefits, hindrances, and suitable applications. By giving a point by point investigation of these perspectives, perusers will acquire an extensive comprehension of how epoxy tar sheets measure facing contending materials, in this manner engaging them to go with very much educated choices for their particular venture necessities. With an emphasis on clarifying the interesting credits and expected downsides of every material, this guide tries to furnish people with the information expected to recognize the most reasonable choice for their planned applications inside different modern and business settings.

1. Understanding Epoxy Resin Sheets

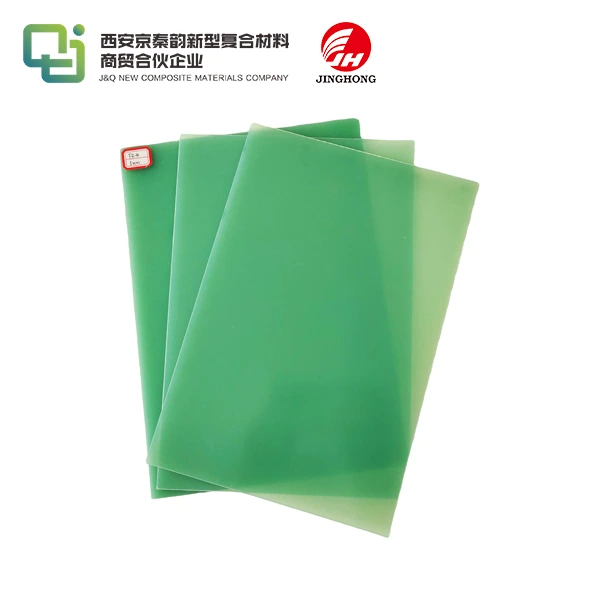

Epoxy Resin Sheets comprise of a mix of epoxy sap and various support materials like fiberglass, carbon fiber, or Kevlar. This mixture delivers a composite material famous for its noteworthy strength, protection from synthetic substances, and layered soundness. Inferable from these remarkable characteristics, epoxy tar sheets find broad application across businesses like aviation, auto, gadgets, and development. Their eminent mechanical properties and ability to persevere through brutal conditions pursue them a favored decision for different requesting applications inside these areas. Whether utilized in the production of elite execution parts for airplane, sturdy primary components in structures, or strong electronic nooks, epoxy gum sheets keep on showing their worth as a flexible and solid material in a wide cluster of modern settings.

2. Comparing Epoxy Resin Sheets with Fiberglass

Fiberglass is a broadly used material perceived for its lightweight nature and noteworthy solidarity to-weight proportion. In an examination between epoxy gum sheets and fiberglass, the two materials grandstand exceptional toughness and erosion obstruction. Nonetheless, epoxy tar sheets stand apart because of their better layered soundness and the capacity than be formed into unpredictable shapes with exact resiliences. These characteristics render epoxy tar sheets especially appropriate for applications that request elaborate plans or tight resiliences. While fiberglass succeeds in giving strength and delicacy, epoxy sap sheets offer an edge in applications where layered exactness and complex molding are basic, pursuing them a phenomenal decision for ventures like aviation, car, and gadgets, where many-sided parts and exact details are fundamental.

3. Evaluating Epoxy Resin Sheets against Carbon Fiber

Carbon fiber is commended for its exceptional strength and firmness, situating it as a top decision for elite execution applications in businesses like aviation and motorsports. Its unrivaled solidarity to-weight proportion separates it; notwithstanding, while contrasting carbon fiber and epoxy sap sheets, the last option present particular benefits regarding cost-adequacy and simplicity of manufacture. Epoxy Resin Sheets can be created in enormous volumes at a lower cost than carbon fiber, making them a more prudent choice for specific applications without forfeiting execution. This cost effectiveness goes with epoxy sap sheets an engaging decision for enterprises hoping to accomplish elite execution qualities while overseeing creation costs. By offering a harmony among execution and moderateness, epoxy sap sheets track down a specialty in different applications inside enterprises like auto, marine, and outdoor supplies, where cost contemplations assume a huge part close by execution necessities.

4. Assessing Epoxy Resin Sheets versus Aluminum

Aluminum is a common metal eminent for its lightweight nature, erosion obstruction, and superb warm conductivity. Interestingly, while comparing epoxy tar sheets with aluminum, every material presents particular benefits in light of explicit application requests. While aluminum flaunts unrivaled warm and electrical conductivity, epoxy sap sheets succeed in consumption obstruction and the capacity to redo mechanical properties through support materials. Besides, epoxy gum sheets offer the additional advantage of being non-conductive, delivering them reasonable for applications wherein electrical protection is principal. This trademark makes epoxy sap sheets especially appropriate for use in ventures like hardware, aviation, and marine designing, where the requirement for consumption opposition and electrical protection offsets the interest for warm conductivity, consequently showing the flexibility and versatility of epoxy pitch sheets across different modern areas.

5. Comparing Epoxy Resin Sheets with Polycarbonate

Polycarbonate, a straightforward thermoplastic prestigious for its effect opposition and optical clearness, is frequently contrasted and epoxy gum sheets. The two materials show fantastic effect obstruction and straightforwardness; nonetheless,FR4 Epoxy Glass Cloth Laminated Sheet outperform polycarbonate regarding substance obstruction and layered steadiness. This makes them appropriate for applications where openness to unforgiving synthetic compounds or outrageous temperatures is a worry. Moreover, epoxy gum sheets offer the adaptability to be tweaked with different added substances to improve explicit properties like fire retardancy or UV obstruction, in this way extending their scope of possible applications. With these benefits, epoxy sap sheets track down huge utility in enterprises like compound handling, development, and hardware, where the interest for strong, artificially safe materials with adaptable properties is fundamental for guaranteeing long haul execution and unwavering quality.

Conclusion

All in all, the decision between epoxy sap sheets and different materials relies upon different factors like application necessities, cost contemplations, and execution assumptions. While epoxy tar sheets offer remarkable benefits with regards to sturdiness, compound obstruction, and layered dependability, it's fundamental to assess the particular necessities of each venture prior to settling on a choice cautiously. By understanding the distinctions between epoxy pitch sheets and different materials, you can go with informed decisions to improve execution and accomplish wanted results.

Contact us

For professional manufacturing expertise and high-quality FR4 Epoxy Glass Cloth Laminated Sheet, contact us at info@jhd-material.com. As a GMP factory with a large inventory and complete certificates, we support OEM orders with fast delivery and tight packaging. Partner with us to access premium products and comprehensive support for your projects.

References

- "Epoxy Resin Composite Materials: Structure and Properties" - A. A. Lebedev et al.

- "Fiberglass Reinforced Polymer Composites" - L. C. Hollaway

- "Carbon Fiber Composites" - Deborah D. L. Chung

- "Aluminum and Aluminum Alloys" - J. R. Davis

- "Polycarbonate Materials for High-Performance Applications" - M. R. Landry et al.

_1747991245292.webp)