Why can't the PCB traces go at a right angle of 90 degrees?

2022-05-17

Now, whenever you open the original pcb Layout Guide of the SoC, you will mention the corner angle of the high-speed signal traces. They will say that high-speed signals should not be traced at right angles, but should be traced at a 45-degree angle. Better than a 45-degree corner.

Is this the case? How to set the PCB trace angle, is it better to go 45 degrees or arc? Is 90-degree right-angle wiring okay?

|

Everyone began to be entangled in the corner angle of the pcb line, which is a matter of the past ten or twenty years. In the early 1990s, the overlord of the PC industry, Intel, led the customization of the PCI bus technology.

(Thanks to Intel for releasing the PCI interface, it is with the bandwidth improvement of the PCI bus interface, including the later AGP bus interface, that graphics cards like 3DFX VOODOO Voodoo were born, and I also experienced the Tomb Raider at that time. In retrospect, it was the market demand for multimedia applications such as 3D games that promoted the development of PC technology, including the later Internet and The spread of smartphones.)

It seems that starting with the PCI interface, we have entered an era of "high-speed" system design.

After the 1990s, it was the desire of a group of players for 3D performance, which enabled the corresponding electronic design and chip manufacturing technology to develop in accordance with Moore's Law. Due to the continuous improvement of IC process technology, IC transistor switches The speed is getting faster and faster, the clock frequency of various buses is getting faster and faster, and the problem of signal integrity is constantly attracting everyone's research and attention. For example, people's demand for 4K high-definition home video and audio, HDMI2.0 transmission standard rate has reached 18Gbps! ! !

Before I was born, pcb pull thread bacteria should be relatively simple classmates, just pull the line, smooth, neat and beautiful, without paying attention to various signal integrity issues. For example, the circuit board of HP's classic HP3456A six-and-a-half-digit multimeter shown in the figure below shows a large number of 90° angle traces.

The HP3456A has no teardrops, and it is almost deliberately taken at right angles (some places originally completed an oblique angle, but it has to go several right angles in a row), and most places are not covered with copper.

Can the PCB be traced at an acute angle?

Whether the PCB can be routed at an acute angle, the answer is no, regardless of whether the acute-angle route will have a negative impact on the high-speed signal transmission line, from the PCB DFM aspect alone, the acute-angle route should be avoided.

Because when the PCB wires intersect to form an acute angle, it will cause a problem called "acid traps", what? Sour beans? Okay, love the sour bean noodles, but the sour bean on the pcb here is a nuisance. In the process of pcb board making, in the pcb circuit etching process, the "acid traps" will cause excessive corrosion of the pcb circuit, resulting in the problem of virtual break of the pcb circuit.

Although, we can use CAM 350 for DFF Audit to automatically detect potential problems with "acid traps" to avoid processing bottlenecks during PCB manufacturing. If the pcb board factory technicians detect the existence of acid traps, they will Simply stick a piece of copper into this gap.

Many engineers of board factories do not know layout, they just repair the acid trap problem from the perspective of PCB engineering, but whether this repair will bring further signal integrity problems It is unknown, so we should try to avoid acid traps from the source in the layout.

How to avoid acute angle when pulling the wire, causing acid trap DFM problem? Modern EDA design software (such as Cadence Allegro, Altium Designer, etc.) all come with complete Layout routing options. We use these auxiliary options flexibly in the layout routing, which can greatly avoid our production of "layout" in the layout. "acid trap" phenomenon

Pad outlet angle setting Avoid acute angle between the wire and the pad.

Can the pcb layout be routed at 90°?

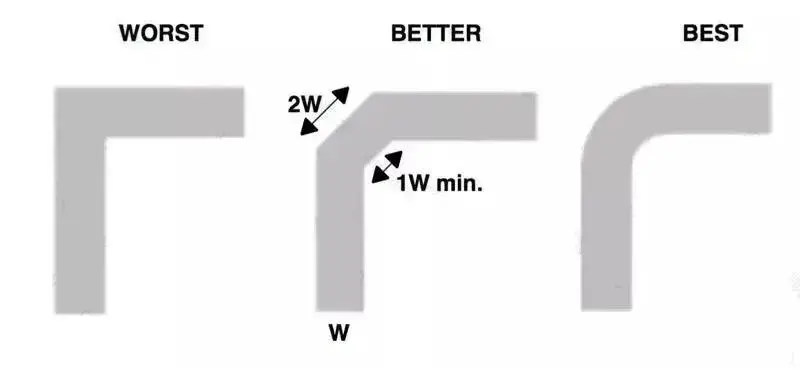

High-frequency and high-speed signal transmission lines should avoid routing with 90° corners, which is strongly required in various PCB Design Guides, because high-frequency and high-speed signal transmission lines need to keep the characteristic impedance consistent, and 90° corner routing is used at the corner of the transmission line. , will change the line width. The line width at the 90° corner is about 1.414 times the normal line width. Because the line width changes, it will cause signal reflection. At the same time, the extra parasitic capacitance at the corner will also cause time-consuming signal transmission. delayed impact.

Of course, when the signal propagates along the uniform interconnection line, there will be no reflection and distortion of the transmitted signal. If there is a 90° corner on the uniform interconnection line, it will cause a change in the width of the pcb transmission line at the corner. According to the correlation Electromagnetic theory calculates that this will definitely bring about the reflection effect of the signal.

This is the case in theory, but theory is theory after all. Is the impact of 90° corners on high-speed signal transmission lines important in practice?

For example, for example, classmate Wang Shi Cong (here classmate Wang is purely fictional for the sake of the plot, no biological father would choose such a name for his son, if there are any similarities, it is purely an honor, O(∩ _∩)O~) took their Erha and Nvpin to make hot pot, and saw a hundred dollars dropped by the roadside, do you think he would pick it up or not?

Picking up this hundred yuan would theoretically increase Wang Decong's personal wealth by another hundred yuan, but for Wang classmates who just found a female ticket and swiped a card to buy a luxury car, such as buying cabbage, it can be completely ignored. And for me, that's a lot of money, and I usually just rush over and pretend to tie my shoelaces...

Therefore, a 90° corner will have a negative impact on high-speed signal transmission lines, which is theoretically certain, but is this impact fatal? Does the 90° corner have the same effect on high-speed digital signals and high-frequency microwave signal transmission lines?

According to the paper "right angle corners on printed circuit board traces, time and frequency domain analysis" and the paper "Who's Afraid of the Big Bad Bend?" by Howard Johnson and the book "Signal Integrity and Power Integrity" by Eric Bogatin Analyzing the content of Chapter 8 (Second Edition), we can draw the following conclusions:

For high-speed digital signals, a 90° corner will have a certain impact on high-speed signal transmission lines. For our current high-density and high-speed pcb, the general trace width is 4-5mil, and the capacitance of a 90° corner is about 10fF. It is estimated that the cumulative delay caused by this capacitor is about 0.25ps, so a 90° corner on a wire with a 5mil line width will not have a great impact on the current high-speed digital signal (100-psec rising edge time).

For high-frequency signal transmission lines, in order to avoid signal damage caused by the skin effect, a wider signal transmission line is usually used, such as 50Ω impedance and 100mil line width. The line width at the 90° corner is about 141mil, the signal delay caused by parasitic capacitance is about 25ps. At this time, the 90° corner will have a very serious impact.

At the same time, microwave transmission lines always hope to minimize the loss of the signal. The impedance discontinuity at the 90° corner and the parasitic capacitance outside will cause the phase and amplitude errors of the high-frequency signal, the mismatch between the input and the output, and the possible existence of Parasitic coupling, which in turn leads to the deterioration of circuit performance, affects the transmission characteristics of PCB circuit signals.

Regarding the 90° signal routing, Lao Wu's own point of view is to try to avoid 90° routing, Nani? Didn't it say earlier that the impact of 90° corners on high-speed digital signals can be ignored?

Of course, the ones written above are to make up the number of words, O(∩_∩)O~, the influence of a single 90° corner on the signal quality of the high-speed digital transmission line, relative to the deviation of the height of the wire and the reference plane, the wire itself is etched In the process, the variation deviation of the line width and line spacing uniformity, the change of the dielectric constant of the sheet on the frequency signal, and even the influence of the parasitic parameters of the via are much larger than the problems caused by the 90° corner.

However, today's high-speed digital circuit transmission lines always have to be wound around the same length. When more than ten or twenty corners are superimposed, the signal rise delay caused by the cumulative effect of these 90° corners will become non-negligible. The high-speed signal is always transmitted along the impedance path, with 90° corners of equal length, and the final actual signal transmission path will be slightly shorter than the original.

And now the high-speed digital signal transmission rate is getting higher and higher, the current HDMI2.0 standard, the transmission bandwidth rate has reached 18Gbps, the 90° corner wiring will no longer meet the requirements, and it is now the 21st century, now The EDA software of 45° has been well supported even by those that use it.

At the same time, routing cables at 90° corners is not in line with people's aesthetics in terms of engineering aesthetics. Therefore, for the current layout, whether you are using high-frequency/high-speed signal lines, we should try to avoid routing with 90° corners unless there are special requirements.

For high-current traces, sometimes we replace the traces with copper-clad copper sheets. At the corners of the copper-clad, we also need to replace the 90° corners with two 45° corners, which is not only beautiful, but also free from EMI. hidden danger.

Route at 45°

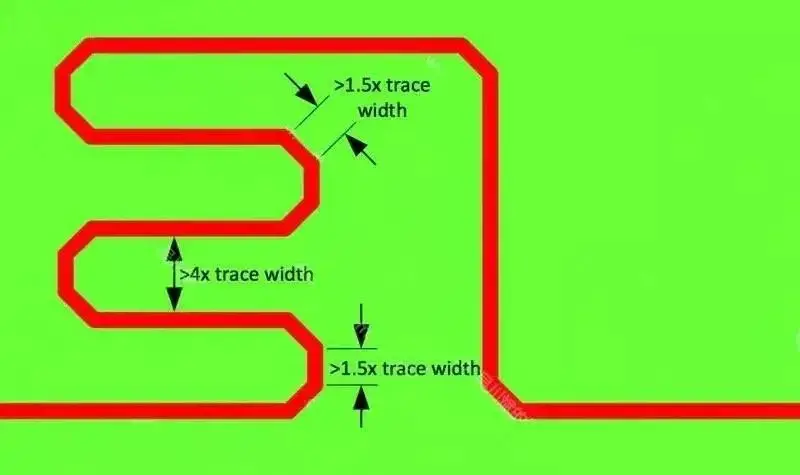

Except for RF signals and other signals with special requirements, the traces on our PCB should preferably be traced at 45°. It should be noted that when the 45° angle trace is wound around the same length, the trace length at the corner should be at least 1.5 times the line width, and the distance between the lines with the same length should be at least 4 times the line width.

Since high-speed signal lines are always transmitted along the path of impedance, if the distance between the lines of equal length is too close, due to the parasitic capacitance between the lines, the high-speed signal takes a shortcut, and the equal length will be inaccurate. The winding rules of modern EDA software can easily set the relevant winding rules.

|

trace in arc

If it is not clearly required by the technical specification to be routed in an arc, or an rf microwave transmission line, I personally feel that there is no need to go for an arc, because of the layout of high-speed and high-density pcb, a large number of arc lines are very troublesome to repair later, and A large number of curved traces are also more space-consuming.

Route at any angle

With the development of 4G/5G wireless communication technology and the continuous upgrading of electronic products, the current PCB data interface transmission rate has reached 10Gbps or more than 25Gbps, and the signal transmission rate is still developing towards high speed. With the development of high-speed and high-frequency signal transmission, higher requirements are put forward for PCB impedance control and signal integrity.

For digital signals transmitted on PCB boards, many dielectric materials, including FR4 Fiberglass Sheet , used in the electronics industry have always been considered uniform for low-speed and low-frequency transmission.

However, when the electronic signal rate on the system bus reaches the Gbps level, this uniformity assumption no longer holds. At this time, the local relative permittivity of the dielectric layer caused by the gap between the glass fiber bundles interwoven in the epoxy resin substrate The change will not be ignored, and the local perturbation of the dielectric constant will make the delay and characteristic impedance of the line related to space, thus affecting the transmission of high-speed signals.

The test data based on the FR4 Fiberglass Sheet test substrate shows that due to the relative position difference between the microstrip line and the glass fiber bundle, the effective dielectric constant of the measured transmission line fluctuates greatly, and the difference between the values can reach Δεr=0.4. Although these spatial perturbations may seem small, they can seriously affect differential transmission lines with data speeds of 5-10Gbps.

In some high-speed design projects, in order to deal with the impact of glass fiber effect on high-speed signals, we can use zig-zag routing technology to mitigate the impact of glass fiber effect.

Cadence Allegro PCB Editor 16.6-2015 and later versions bring support for zig-zag routing mode.

In the Cadence Allegro PCB Editor 16.6-2015 menu, select "Route -> Unsupported Prototype -> Fiber Weave Effect" to enable zig-zag routing.

Years are killing pigs, just like twenty years ago, we don't need to pay attention to whether we need to take the arc line or not, and we don't need to worry about the impact of the glass fiber of the PCB board on the high-speed signal. Maybe when you read this text 20 years later, you will feel that the views of Lao Wu are quite out...

Therefore, there are no fixed pcb layout rules, and with the improvement of pcb manufacturing process and data transfer rate, it is possible that the correct rules now will become no longer applicable in the future. Therefore, in order to be a qualified pull thread fungus, we must keep pace with the times and master the development of the industrial technology direction, so as not to be eliminated by the big waves.