Formula and Production Process of Epoxy Floor Paint

2023-03-03

Standard epoxy floor paint formula

Primer:

1. Epoxy resin e51 (epoxy equivalent is 190): 90 parts

Active diluent BGE (epoxy equivalent 190) or D-1214:10 parts

Curing agent H-113: 50 parts

2. Epoxy resin GESN-901 * 75 (epoxy equivalent 450-500, 75% solid content): 100 parts

Solvent: proper amount

Curing agent H-113:15 parts

Or curing agent (H-113 75 parts+xylene 25 parts): 20 parts

Intermediate coating:

epoxy resin e51 (epoxy equivalent is 190): 45-53 parts

Active diluent BGE (epoxy equivalent 190) or D-1214:5-7 parts

Silica powder (325 mesh - 400 mesh): 40-50 parts

Defoamer and leveling agent: appropriate

Curing agent H-113: 25-30 parts

Resin mortar: epoxy resin 128 90 parts+10 parts of BGE (or D-1214) and 50 parts of H-113. After mixing evenly, add 4-6 times of quartz sand, or add 3-4 times of quartz sand on the basis of intermediate coating.

Surface coating:

epoxy resin e51:45-53 copies

Active diluent D-1214:5-7 parts

Calcium phosphate and other fillers: 40-50 parts

Defoamer, leveling agent, epoxy color paste: appropriate

Curing agent: 6892 (for winter use): 25-30 portions

6821 (for summer use) 25-30 copies

Relatively speaking, the dilution effect of BGE is better than that of D-1214, but it has smell, while D-1214 is colorless and tasteless, and the water resistance of the final paint film is better than that of BGE, so it is generally recommended to use D-1214 as the top coating thinner, and BGE as the middle and bottom coating thinner.

Construction process:

1. Ground treatment: polish, repair, remove dirt and dust according to the ground conditions;

2. Epoxy primer: apply one layer of super permeable and adhesive primer to enhance surface adhesion;

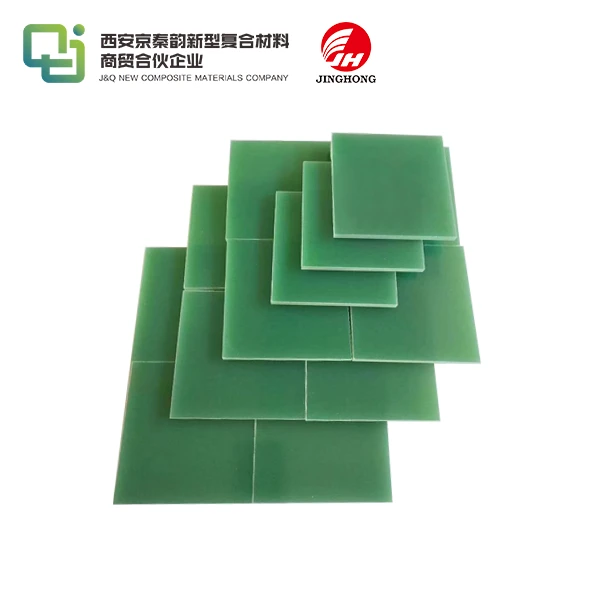

3. Glass fiber laying: use glass fiber cloth to lay one layer;

4. Epoxy mortar: add epoxy two-component into quartz sand, and evenly coat it with a trowel for multiple layers;

5. Epoxy putty: add proper amount of putty powder with epoxy two-component, and evenly coat it with a trowel for multiple layers;

6. Heavy-duty anticorrosive finish: roll two to three coats of heavy-duty anticorrosive finish;

7. The time when the floor is put into use: subject to 250C, people can get on after 24 hours, and can be heavily pressed after 72 hours. When the temperature is low, the interval time needs to be appropriately extended.