What are the properties of FR4 Epoxy Sheets?

2024-06-04 13:58:10

What are the Properties of FR4 Epoxy Sheets?

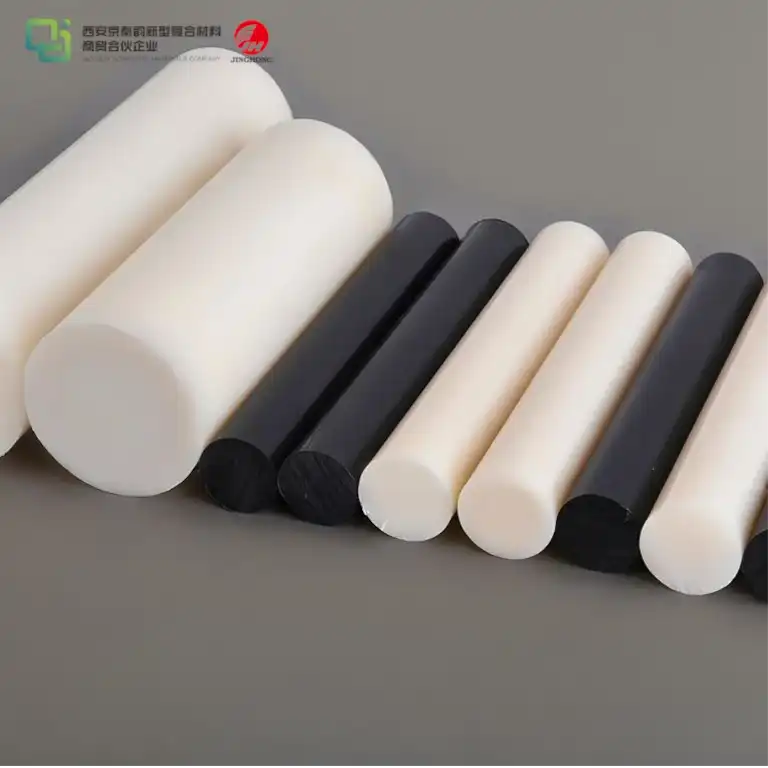

Epoxy Resin Sheets, made out of woven fiberglass fabric impregnated with epoxy sap, show uncommon mechanical strength, electrical protection, and warm steadiness. They offer high malleable and flexural strength, making them reasonable for underlying parts. With magnificent electrical protection and high dielectric strength, they forestall the electrical flow streams, which is ideal for hardware. FR4 sheets endure high temperatures without critical deformity, guaranteeing dependability in requesting conditions. Also, they oppose erosion from acids, antacids, and solvents, upgrading life span. FR4 epoxy sheets are correspondingly steady, lightweight, and fire-safe, further widening their applications in businesses like hardware, aviation, and auto, where toughness and execution are basic. Here, I’ll delve into the key characteristics of FR4, offering a comprehensive look at why these materials are so highly valued, particularly in electronic and electrical engineering applications.

Physical and Mechanical Properties

FR4 epoxy sheets are composed of woven fiberglass cloth and an epoxy resin binder, which contribute to their high mechanical strength and durability. These sheets exhibit excellent tensile strength, typically around 38,000 psi, and impressive flexural strength, which can reach up to 60,000 psi. The hardness is measured on the M scale, with a typical value being around 115 (Curbell Plastics).

These materials are also known for their dimensional stability and low moisture absorption, which makes them suitable for use in a variety of environmental conditions. FR4 Epoxy Sheet is also a flame retardant, classified under the 94V-0 flammability standard, which indicates that they extinguish quickly once the flame source is removed (Atlas Fibre) (Wikipedia).

Thermal Properties

The thermal properties of FR4 epoxy sheets make them reasonable for a large number of utilizations requiring heat obstruction and warm soundness. These sheets show low warm conductivity, meaning they are powerful encasings, limiting intensity movement. This property is important in applications where warm protection is critical, like electrical and electronic parts. FR4 epoxy sheets likewise exhibit fantastic warm steadiness, keeping up with their underlying honesty and properties over a wide temperature range. They can endure raised temperatures without critical twisting or corruption, guaranteeing solid execution in high-temperature conditions. Furthermore, FR4 epoxy sheets have a low coefficient of warm extension, meaning they experience negligible layered changes with temperature variances, guaranteeing exact resistances in applications. Besides, they show great intensity obstruction, holding their properties much under delayed heat openness. Generally, the great warm properties of FR4 epoxy sheets, including low warm conductivity, warm soundness, low coefficient of warm extension, and intensity opposition, make them important materials in businesses like hardware, aviation, and auto, where warm administration is basic.

Electrical Properties

The electrical properties of Epoxy Resin Sheets are vital to their far and wide use in different ventures, especially in gadgets and electrical design. These sheets display magnificent electrical protection properties, actually forestalling the progression of electric flow and limiting the gamble of shortcircuits. FR4 epoxy sheets additionally have high dielectric strength, empowering them to endure high voltage levels without breakdown, making them reasonable for protection in transformers, capacitors, and circuit sheets. Furthermore, they have low scattering variables and dielectric steady, showing insignificant energy misfortune and proficient transmission of electrical signs. This makes them ideal for high-recurrence and high-velocity applications where signal trustworthiness is urgent. Moreover, FR4 epoxy sheets offer great layered steadiness and mechanical strength, guaranteeing solid execution in requesting electrical conditions. In general, the remarkable electrical properties of FR4 epoxy sheets, including protection capacity, high dielectric strength, low scattering factor, and layered dependability, make them essential materials in the electrical and hardware industry.

Chemical and Environmental Resistance

FR4 epoxy sheets brag noteworthy synthetic and ecological opposition, delivering them significantly in testing modern settings. These sheets show remarkable protection from a great many synthetic compounds, including acids, soluble bases, solvents, and destructive substances usually experienced in different ventures. Their opposition guarantees life span and dependability, as they keep up with underlying respectability in any event when presented with cruel compound conditions. Furthermore, FR4 epoxy sheets are idle, meaning they don't respond with numerous synthetics, forestalling pollution and guaranteeing the immaculateness of encompassing materials. Moreover, they display great natural opposition, enduring variables like dampness, stickiness, and temperature vacillations without compromising execution. This strength makes them reasonable for open-air applications where openness to natural components is unavoidable. In general, the noteworthy compound and natural opposition of FR4 epoxy sheets, combined with their solidness and unwavering quality, make them basic materials in enterprises like hardware, aviation, auto, and assembling, where assurance against synthetic erosion and ecological variables is fundamental for long haul execution.

Applications

FR4 Epoxy Sheet is widely utilized in hardware for printed circuit sheets (PCBs), attributable to their prevalent electrical protection and warm steadiness. They track down applications in aviation for lightweight underlying parts and auto for motor parts and electrical frameworks. Furthermore, they serve in the development for building boards and protection sheets, profiting from their sturdiness and imperviousness to fire. Different purposes incorporate marine gear, environmentally friendly power frameworks, and modern hardware parts. Their flexibility, unwavering quality, and execution make them fundamental across different ventures, where rigid prerequisites for electrical, mechanical, and warm properties are critical for ideal execution and life span.

Contact Us

As a GMP-certified manufacturing supplier, we offer high-quality Epoxy Resin Sheets from our extensive inventory, complete with all necessary certifications. Our products support OEM customization, ensuring that your specific needs are met with precision. With fast delivery, secure packaging, and support for testing, we are dedicated to meeting the demands of global buyers. Partner with us for reliable supply and expert service at info@jhd-material.com.

This comprehensive overview of FR4 epoxy sheets underscores their critical role in various industrial applications, reflecting their reliability and adaptability in challenging environments. For more detailed specifications or to discuss potential applications, feel free to reach out as mentioned above.

拷贝.webp)

拷贝_1755500211555.jpg)