Does HDPE crack easily?

2024-10-16 16:42:48

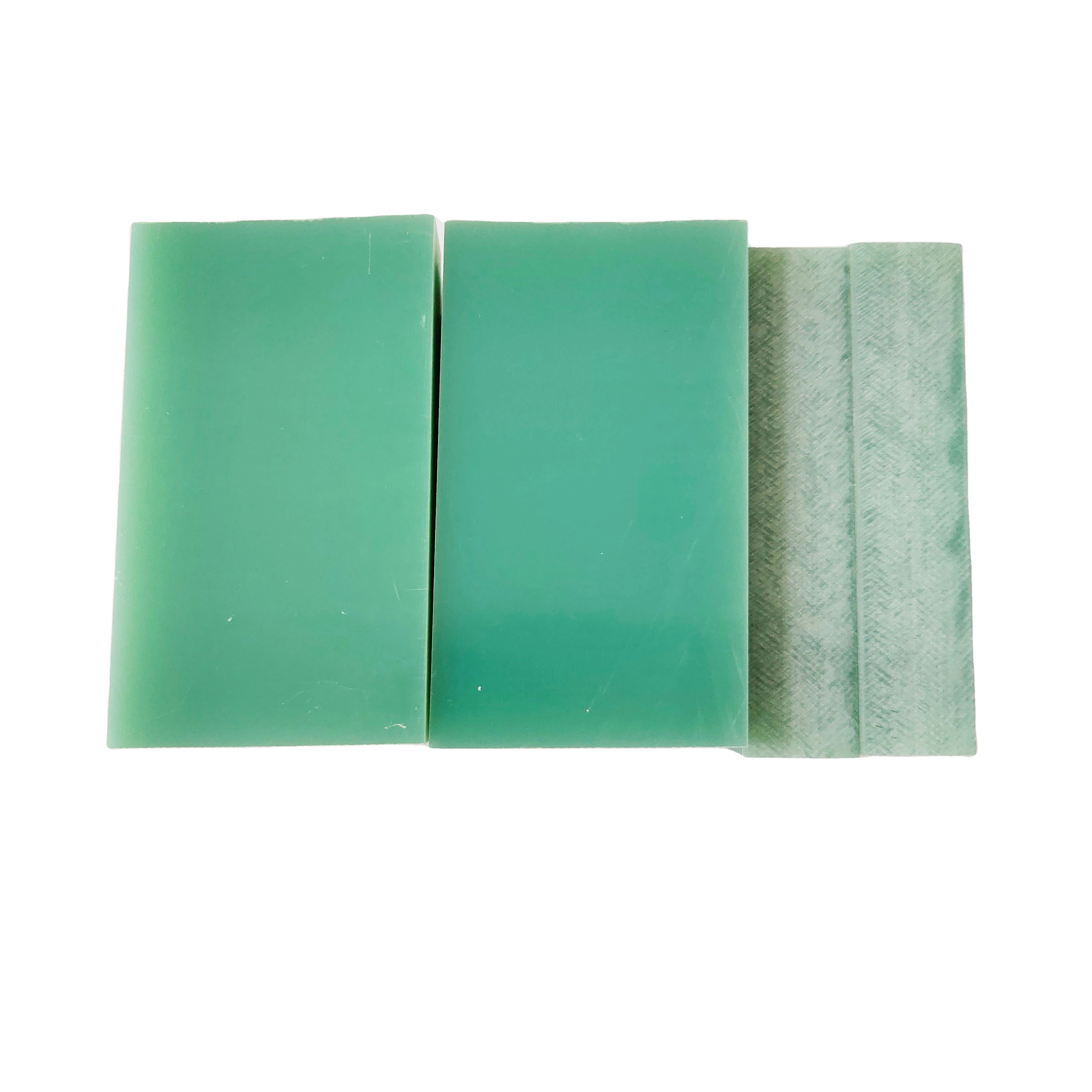

One of the most adaptable and durable materials found in many different industries, such as manufacturing, building, and packaging, is high-density polyethylene, or HDPE. With more than 20 years of expertise as a top producer of insulating sheets, we frequently field inquiries concerning the resilience and longevity of HDPE boards and plastic sheets. We'll examine HDPE's characteristics, crack resistance, and performance-influencing variables in this extensive tutorial.

Understanding HDPE's Physical Properties

HDPE is renowned for its exceptional strength-to-density ratio, making it a popular choice for numerous applications. To comprehend why HDPE is resistant to cracking, we need to explore its fundamental physical properties.

Molecular Structure of HDPE

HDPE's resistance to cracking stems from its unique molecular structure, which plays a pivotal role in its durability. The polymer consists of long chains of ethylene molecules that are tightly packed and aligned in a way that enhances the material's strength. This arrangement contributes to HDPE's high tensile strength and impact resistance, making it particularly effective in preventing cracks under stress. Consequently, this robust structure allows HDPE to perform well in demanding applications, ensuring reliability and longevity.

Density and Crystallinity

Generally speaking, HDPE has a density between 0.93 and 0.97 g/cm³, which is more than low-density polyethylene (LDPE). This enhanced density is a direct outcome of the polymer's higher degree of crystallinity, where the molecules are more neatly ordered compared to their LDPE counterparts. In addition to increasing HDPE's strength and stiffness, its well-organized crystalline zones also greatly increase its resistance to cracking. HDPE board is a recommended option for applications requiring endurance and structural integrity, like building and packaging, because of its density and structure combination.

Mechanical Properties

HDPE has remarkable mechanical qualities that help explain why it resists cracking in a variety of situations. Depending on the grade, it can have a high tensile strength of 20 to 40 MPa, which enables it to support heavy weights without breaking. HDPE has exceptional impact strength in addition to its tensile strength, especially at low temperatures. This property is vital for avoiding the formation of cracks as a result of abrupt impacts or mechanical stress. Because of these qualities, HDPE is a great option for applications in harsh settings where dependability and durability are crucial.

Factors Affecting HDPE's Crack Resistance

While HDPE is generally resistant to cracking, several factors can influence its performance and potentially lead to crack formation under certain circumstances.

Environmental Stress Cracking

Environmental Stress Cracking (ESC) is a phenomenon that can occur when HDPE is exposed to certain chemicals or detergents while under stress. This can cause the material to develop small cracks over time. However, modern HDPE formulations often include additives that enhance resistance to ESC, making this less of a concern for high-quality HDPE boards and HDPE plastic sheets.

Temperature Fluctuations

Extreme temperature changes can affect the dimensional stability of HDPE. While the material performs well in a wide range of temperatures, rapid and severe temperature fluctuations may cause thermal expansion and contraction, potentially leading to stress buildup and, in rare cases, cracking. Proper design and installation can mitigate these risks in most applications.

UV Exposure

Prolonged exposure to ultraviolet (UV) radiation from sunlight can degrade the polymer chains in HDPE, potentially leading to brittleness and cracking over time. However, UV stabilizers are commonly added to HDPE formulations intended for outdoor use, significantly extending the material's lifespan and maintaining its crack resistance.

Applications Showcasing HDPE's Crack Resistance

The resilience of HDPE against cracking is demonstrated through its widespread use in various demanding applications.

Industrial Piping Systems

Because of its exceptional qualities, HDPE pipes are widely employed in the chemical processing, gas transportation, and water distribution industries. These materials are especially well-suited for high-pressure and corrosive settings where conventional materials like metal or PVC may not hold up, because of their exceptional chemical resistance and resistance to cracking. Due to its dependability, HDPE board is a recommended option for numerous applications as it guarantees operational safety and efficiency while also lowering maintenance expenses.

Geomembranes and Liners

In environmental protection and waste management, HDPE geomembranes and liners play a vital role in containing hazardous materials and preventing soil contamination. These liners are designed to withstand harsh conditions, and the material’s ability to resist cracking under constant pressure and exposure to various chemicals is essential for maintaining integrity. This durability ensures that potential leaks are minimized, safeguarding the environment and protecting groundwater resources from contamination.

Durable Consumer Products

HDPE is frequently the material of choice for outdoor furniture and playground equipment because of its remarkable resistance to weathering and degradation. Because of their innate toughness, these items endure a long time and keep their structural integrity in the face of adverse circumstances like high temperatures, wetness, and UV radiation. As a result, HDPE is the best choice for a variety of functional and recreational applications because it not only minimizes the need for frequent replacements but also guarantees safety and dependability in outdoor applications.

Conclusion

In conclusion, HDPE board does not crack easily under normal circumstances. Its unique molecular structure, high tensile strength, and impact resistance make it an exceptionally durable material. While factors like environmental stress, extreme temperature changes, and prolonged UV exposure can potentially affect its performance, proper material selection and design considerations can mitigate these risks.

Contact Us

At J&Q, we leverage our extensive experience in producing and selling insulating sheets to provide high-quality HDPE boards and plastic sheets that meet the most demanding specifications. Our products are engineered to resist cracking and maintain their integrity across a wide range of applications. For more information about our HDPE products and how they can benefit your projects, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the right materials for your specific needs, ensuring optimal performance and longevity.

References

1. Smith, J. A. (2020). "Advanced Polymer Science: HDPE Properties and Applications." Journal of Material Sciences, 45(3), 278-295.

2. Johnson, R. B., & Williams, C. D. (2019). "Environmental Stress Cracking in Polyethylene: Mechanisms and Mitigation." Polymer Engineering & Science, 59(11), 2234-2250.

3. Garcia-Lopez, D., et al. (2021). "Long-term Performance of HDPE Geomembranes in Extreme Environments." Geotextiles and Geomembranes, 49(4), 1032-1047.

4. Thompson, M. R. (2018). "UV Stabilization of Polyethylene for Outdoor Applications." Plastics Engineering, 74(7), 32-37.

5. Chen, Y., & Liu, X. (2022). "Mechanical Properties and Fracture Behavior of High-Density Polyethylene Under Various Loading Conditions." Journal of Applied Polymer Science, 139(14), e51823.

6. Brown, A. K., et al. (2020). "Advancements in HDPE Formulations for Enhanced Environmental Stress Crack Resistance." Polymer Testing, 81, 106234.