Can Bakelite Board Withstand Chemical Exposure?

2024-08-01 17:22:17

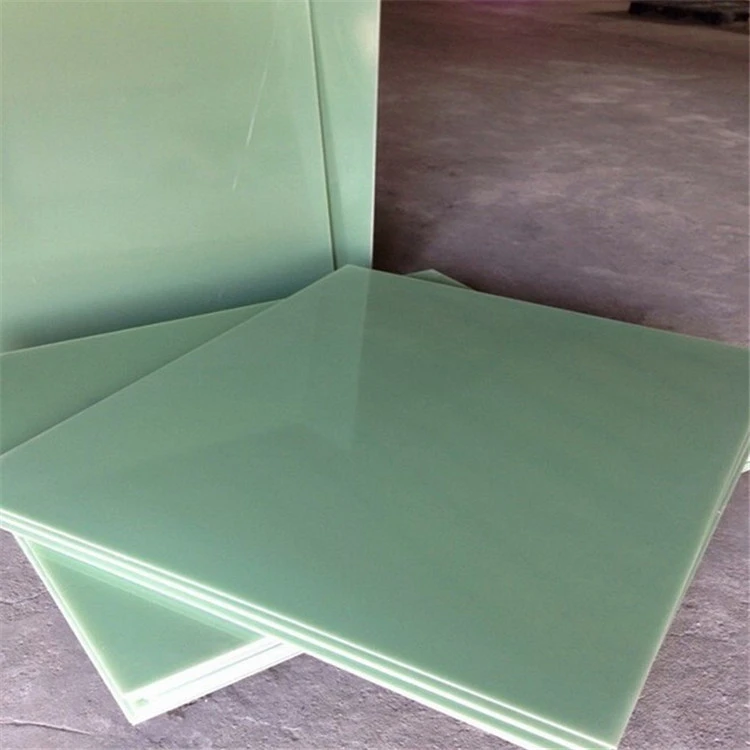

Phenolic resins such as bakelite board are well known for their strength and adaptability in a range of industrial settings. Its resilience to chemical exposure is one of the main elements influencing its extensive use. This blog examines Bakelite board's chemical resistance as well as how well it functions in chemically exposed conditions. We shall examine Bakelite board's resistance to chemical exposure, its functionality in industrial settings, and its benefits over alternative materials.

How Does Bakelite Board Resist Chemical Degradation?

Compound obstruction is one of the major attributes that makes bakelite board appropriate for various applications. Due to its distinctive chemical structure and properties, it can withstand chemical exposure without deterioration.

Formaldehyde and phenol are combined through polymerization to create synthetic structure bakelite, a thermostable plastic. Cross-connecting produces a phenolic sap network that is very synthetically safe and unbending in three aspects. This structure maintains its stability and integrity by preventing the penetration of numerous chemicals into the material and their reaction with it.

Cross-Communicating Thickness

The level of cross-partner in Bakelite's polymer structure contributes completely to its substance opposition. A material with a high cross-interfacing thickness leaves less room for manufactured mixtures to penetrate and interact with it. which is less likely to swell, soften, or dissolve when exposed to solvents and other chemicals because of its dense network.

which is incredibly resistant to both acids and salts, despite its corrosive and basic resistance. This opposition is expected for applications in compound handling plants, research centers, and different places where destructive substances are much of the time experienced. Bakelite doesn't promptly respond with most of acids, for example, sulfuric, hydrochloric, and nitric acids, as well as bases can imagine sodium hydroxide and potassium hydroxide.

Performance in Relation to Organic Solvents Bakelite board's performance can be affected by the solvent used, despite its general resistance to many organic solvents. Because it works against alcohols, oils, and some hydrocarbons, it can be used anywhere safely. However, when compared to other materials, exposure to powerful solvents like acetone or toluene may result in some degradation.

Natural Dependability it's substance resistance extends to its ecological toughness, allowing it to keep its properties even after being exposed to harsh synthetic compounds for a long time. Applications in which materials are anticipated to be exposed to chemicals for an extended period of time without compromising their structural integrity or performance necessitate this stability over time.

Overall, it's substance resistance is enhanced by its robust compound creation, high cross-connecting thickness, and inherent dependability against acids, salts, and various natural solvents. It is a sturdy material for synthetically strenuous environments due to these characteristics.

What Are the Applications of Bakelite Board in Chemical Environments?

Bakelite board is an excellent material for a wide range of applications in various chemical environments due to its exceptional resistance to chemical exposure. These applications cover a wide range of industries and demonstrate Bakelite's adaptability and dependability when working with aggressive chemicals.

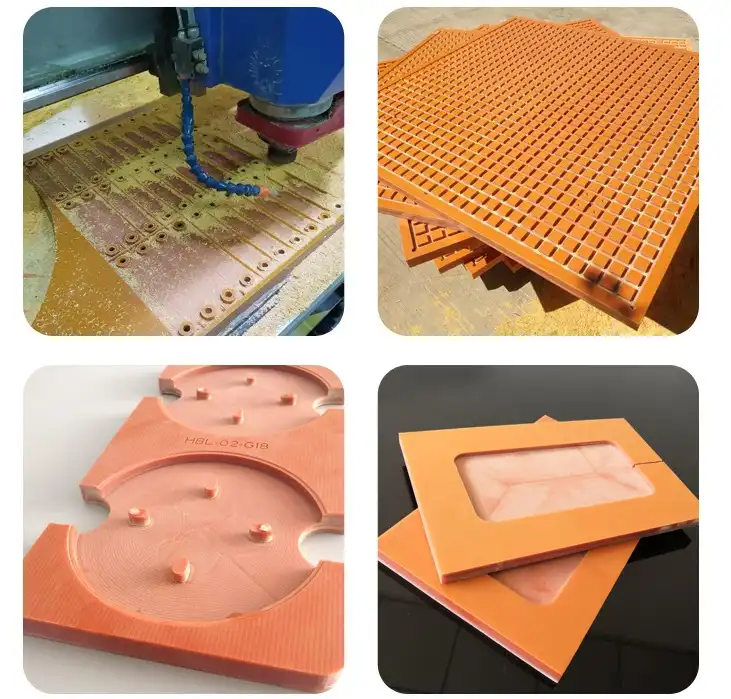

Chemical Processing Plants Materials are constantly exposed to a variety of corrosive substances in chemical processing plants, making chemical resistance an essential consideration when selecting materials. In these facilities, it is frequently used in a number of components and structures:

1. Vessels and liners for tanks: Line tanks and vessels that store or process chemicals with it. The structural integrity of these tanks is not compromised over time due to its resistance to acids, alkalis, and other corrosive substances.

2. Pipes and Fittings: Pipes and fittings used to transport hazardous chemicals are made of it. Leaks and breakdowns in the chemical transport system are prevented by its durability and resistance to chemical attack.

3. Benches and other work surfaces: which is utilized for bench surfaces and work surfaces in laboratories and chemical processing facilities. Bakelite's properties make it an excellent choice for these surfaces, which must withstand chemical splashes and spills without deteriorating or absorbing the substances.

Insulation of Electrical Components in Chemical Environments Due to the possibility of chemical exposure, electrical components in chemical environments face particular difficulties. Due to its dual properties of electrical insulation and chemical resistance,which is ideal for the following applications:

1. Control Panels and Switches: Switchgear and control panels in chemical plants are made of it. The corrosive environment must not affect these panels' ability to function reliably. Bakelite guarantees the components' longevity and electrical safety.

2. Insulators and cable trays: it is utilized to develop link plate and covers that shield electrical wiring and associations from substance openness. Electrical faults are prevented by its insulating properties, and its chemical resistance guarantees long-term performance even in harsh environments.

3. Enclosures and Casings that Protect: Electrical gadgets and instruments in substance plants frequently have defensive housings made of it. These fenced in areas safeguard touchy electronic parts from compound exhaust and sprinkles, keeping up with the usefulness and security of the gadgets.

Equipment for Laboratories Materials that can withstand exposure to a variety of substances are necessary for laboratories, particularly those that deal with aggressive chemicals. Which is generally utilized in lab hardware because of its vigorous substance obstruction:

1. Countertops and Benches for Labs: It is a popular material for countertops and lab benches. It is ideal for surfaces that may come into contact with acids, bases, solvents, and other reagents due to its resistance to a wide range of chemicals.

2. Cabinets for storing chemicals: Which is frequently used to construct cabinets for chemical storage. Bakelite's properties guarantee safe storage, preventing chemical interactions and potential spills in these cabinets.

3. Ventilation and hoods for fumes: In laboratories, fume hoods and ventilation systems are made to control and get rid of dangerous fumes. Which is utilized in these frameworks because of its protection from substance erosion and its capacity to keep up with primary trustworthiness under steady openness to synthetic exhaust.

Bakelite board is used in a variety of industrial applications where chemical exposure is a concern, beyond laboratories and chemical processing:

1. The Automotive Sector: This product is utilized in automotive components that must withstand exposure to coolants, oils, and other fluids. This incorporates gaskets, seals, and different motor parts.

2. The Oil and Gas Sector: In the oil and gas industry, equipment and components that come into contact with hydrocarbons and other chemicals are made of it. The components' dependability and safety in harsh environments are guaranteed by its resistance to chemical degradation.

3. Industry of Food and Beverage: In food handling, gear is frequently presented to cleaning specialists and sanitizers. Components that must withstand these chemicals while adhering to food safety standards use it.

In conclusion, the chemical resistance of the product makes it an invaluable material for a wide range of industries and applications. The dependability and long-term viability of the components and structures it is used in is ensured by its capacity to maintain structural integrity and performance in chemically aggressive environments.

How Does Bakelite Board Compare to Other Materials in Chemical Resistance?

When selecting materials for applications involving chemical exposure, it's essential to compare the performance of this product to other commonly used materials. Understanding these comparisons helps in making informed decisions for specific applications.

Bakelite Board vs. Fiberglass

Fiberglass, composed of glass fibers embedded in a resin matrix, is known for its strength and chemical resistance. However, there are key differences between fiberglass and this product:

1. Chemical Resistance: Both materials exhibit good chemical resistance, but this product typically offers better performance against strong acids and alkalis. Fiberglass may degrade over time when exposed to highly acidic or basic environments.

2. Thermal Stability: Fiberglass can withstand higher temperatures than the product, making it suitable for applications requiring heat resistance. However, in environments where chemical exposure is the primary concern, Bakelite's resistance to chemical degradation can make it a more suitable choice.

3. Mechanical Strength: Fiberglass offers higher tensile strength and impact resistance compared to it. This makes fiberglass preferable in applications where mechanical loads and stresses are significant.

Bakelite Board vs. Polyethylene (PE)

Polyethylene (PE) is a widely used plastic known for its chemical resistance, particularly against acids, bases, and many organic solvents. Comparing it to it:

1. Chemical Resistance: Both materials provide excellent chemical resistance, but it generally offers superior resistance to a broader range of chemicals, including strong acids and solvents.

2. Thermal Properties: PE has a lower melting point compared to this product, limiting its use in high-temperature applications. Bakelite's thermal stability makes it suitable for applications involving both chemical exposure and elevated temperatures.

3. Mechanical Properties: PE is more flexible and less brittle than this product. This flexibility can be advantageous in applications where some degree of deformation is acceptable. However, Bakelite's rigidity and high mechanical strength are preferred in applications requiring structural stability.

Bakelite Board vs. Teflon (PTFE)

Teflon, or PTFE, is renowned for its non-reactivity and use in extreme chemical environments. Comparing it to this product:

1. Chemical Resistance: Teflon offers superior chemical resistance compared to almost any other material, including this product. It remains stable in the presence of virtually all chemicals.

2. Thermal Properties: Teflon can withstand higher temperatures than the product, making it suitable for high-temperature chemical environments.

3. Cost and Availability: Teflon is more expensive and less widely available than the product. For many applications, the high cost of Teflon can be a limiting factor, whereas Bakelite board offers a more cost-effective solution with adequate chemical resistance for most environments.

4. Mechanical Properties: which offers higher mechanical strength and rigidity compared to Teflon. Teflon is softer and more prone to deformation under mechanical stress, whereas Bakelite's rigidity is beneficial in structural applications.

Bakelite Board vs. Stainless Steel

Stainless steel is a metal known for its corrosion resistance and strength, commonly used in chemical environments. Comparing it to Bakelite board:

1. Chemical Resistance: Stainless steel provides excellent resistance to many chemicals but can corrode in the presence of certain acids, such as hydrochloric acid and sulfuric acid. The product, however, can offer better resistance to these specific chemicals.

2. Mechanical Strength: Stainless steel surpasses board in mechanical strength and durability, making it ideal for applications involving high mechanical loads and impacts.

3. Thermal Properties: Stainless steel can withstand much higher temperatures than the product. For high-temperature applications, stainless steel is the preferred choice.

4. Cost and Fabrication: Stainless steel is more expensive and requires more complex fabrication processes compared to it. For many applications, Bakelite provides a cost-effective alternative with sufficient chemical resistance.

In conclusion, while the product offers excellent chemical resistance, its suitability compared to other materials depends on the specific requirements of the application. Each material has its strengths and weaknesses, and the choice should be based on a comprehensive evaluation of chemical resistance, thermal stability, mechanical properties, and cost considerations.

Conclusion

Bakelite board stands out as a reliable material for applications involving chemical exposure due to its robust chemical resistance, thermal stability, and mechanical strength. Its unique properties make it suitable for a wide range of industrial and laboratory environments where exposure to corrosive substances is common. While other materials like fiberglass, polyethylene, Teflon, and stainless steel each have their own advantages, which offers a balanced combination of performance and cost-effectiveness, making it an ideal choice for many chemically aggressive settings.

References

1. "Understanding the Chemical Resistance of Bakelite in Industrial Applications," Chemical Materials Journal.

2. "Comparative Analysis of Chemical Resistant Materials," Industrial Plastics Review.

3. "The Role of Bakelite in Modern Industry," Engineering Materials Today.

4. "Chemical Resistance of Various Materials," Materials Science and Engineering Journal.

5. "Applications of Bakelite Board in Chemical Environments," Industrial Engineering Review.