Can FR4 sheets be used in high-temperature environments?

2024-08-13 15:47:31

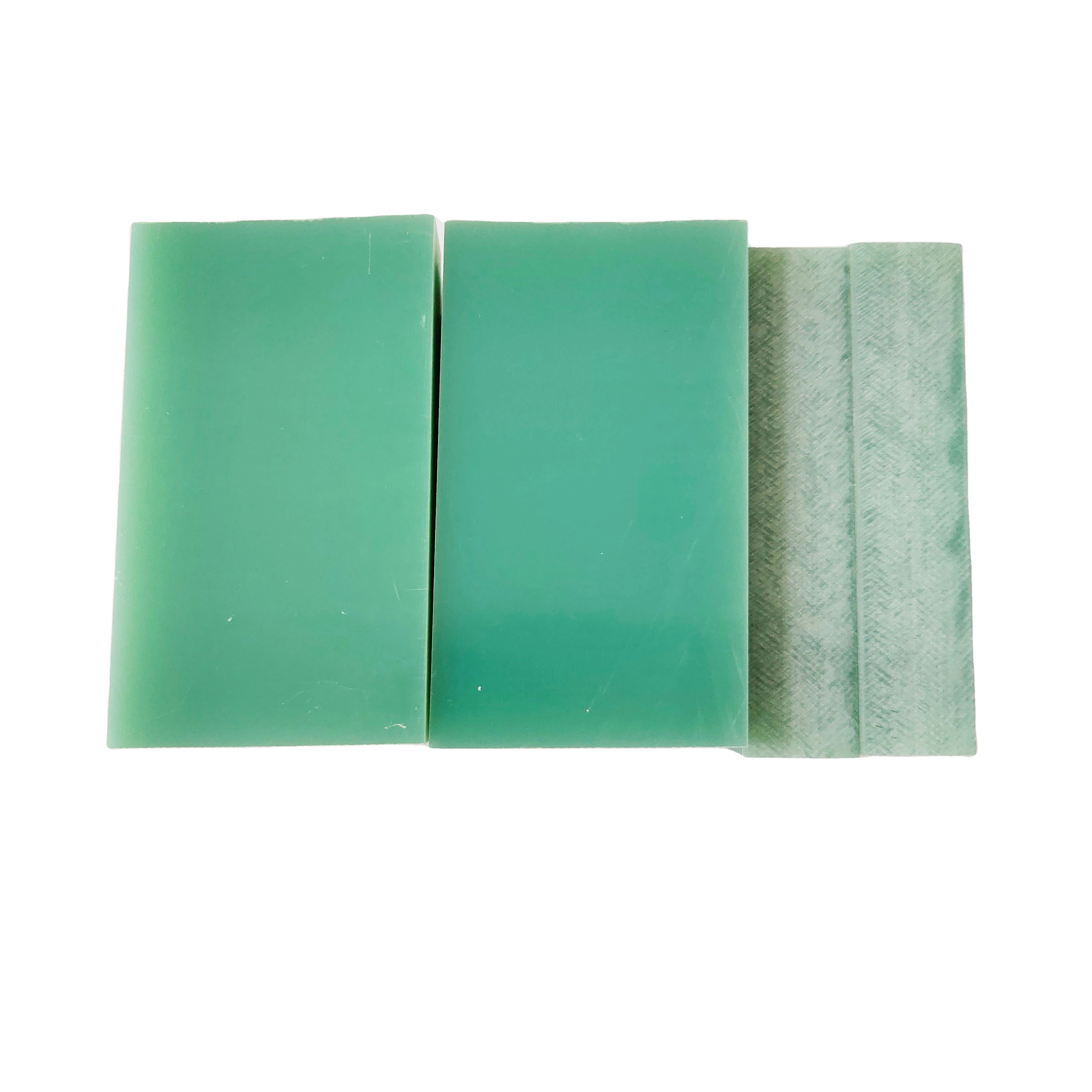

When it comes to selecting materials for electronic applications, FR4 sheets are often a top choice due to their excellent electrical and mechanical properties. However, a common question that arises is whether FR4 sheets can withstand high-temperature environments. In this article, we'll explore the heat resistance capabilities of FR4 sheets and their suitability for high-temperature applications.

FR4 Sheets and High-Temperature Performance

FR4 sheets, a common material in the electronics industry, are widely recognized for their impressive mechanical strength, electrical insulation properties, and flame resistance. These qualities make them a popular choice for printed circuit boards (PCBs) and various industrial applications. However, when it comes to high-temperature environments, it's crucial to understand the limitations of standard FR4 sheets to ensure optimal performance and safety.

Glass Transition Temperature (Tg)

The glass transition temperature (Tg) is a basic property of FR4 sheets that characterizes the temperature range inside which the material holds its unbending and stable design. For standard FR4 sheets, the Tg normally goes from 130°C to 140°C (266°F to 284°F). FR4 is suitable for a wide range of applications because it maintains its excellent mechanical and electrical properties below this temperature range.

Nonetheless, when the temperature surpasses the Tg, the FR4 material starts to mellow. This conditioning can prompt changes in its mechanical properties, like diminished strength and firmness. The electrical properties may also deteriorate, which could have an impact on how well electronic circuits and components work. Consequently, it is indispensable to consider the Tg while planning frameworks that will be presented to raised temperatures.

Performance Beyond Tg

The performance of FR4 sheets can suffer significantly if they are operated above their glass transition temperature. The material may lose its structural integrity, resulting in warping or deformation that could jeopardize the assembly's mechanical stability. Additionally, FR4's insulation properties may degrade, raising the possibility of short circuits or electrical failures.

It is absolutely necessary to investigate alternative or specialized FR4 variants in applications where temperatures are anticipated to exceed the Tg of standard FR4 sheets. High-temperature FR4 variations have been created to address these difficulties, offering further developed execution in raised temperature conditions.

High-Temperature FR4 Variants

Variants of FR4 designed for high temperatures can withstand higher temperatures without significantly affecting their properties. The thermal conductivity (Tg) of these specialized materials is typically higher, ranging from 170°C to 180°C (338°F to 356°F) for the majority of them, and even higher for some grades. Engineers can ensure that the material maintains its mechanical and electrical properties even in harsh thermal conditions by utilizing these high-temperature variants.

The higher performance of high-temperature FR4 variants makes them suitable for high-temperature environments like aerospace, automotive, and industrial electronics. When electronic systems are subjected to thermal stress, these materials offer a dependable solution for preserving their functionality and integrity.

Tips for Enhancing FR4 Performance in High-Temperature

Enhancing the performance of FR4 sheets in high-temperature environments requires careful consideration and strategic measures. Here are some tips to maximize the effectiveness and longevity of FR4 materials under thermal stress:

Choose High-Tg FR4 Variants

Choose FR4 sheets with a higher glass transition temperature (Tg), typically between 170 and 180 degrees Celsius. These variants are made to keep their electrical and structural properties even at high temperatures, which makes them suitable for more difficult applications.

Implement Effective Cooling Systems

Incorporate efficient cooling systems, such as active cooling fans or heat sinks, to dissipate heat from critical areas. By keeping the temperature of FR4 sheets within their operating limits, degradation is prevented.

Use Polyimide-Based FR4

Consider using polyimide-based FR4 sheets for applications requiring extremely high temperatures. Superior thermal stability and dependability in harsh environments are provided by these materials, which can withstand temperatures up to 260°C (500°F).

Apply Thermal Coatings

FR4 sheets' heat resistance can be improved by applying thermal coatings or insulative layers. The material's overall performance can be enhanced by these coatings by providing an additional heat barrier.

Optimize Design and Layout

Consider heat management when designing your PCBs and other assemblies. To improve heat dissipation and distribution, use thermal vias and ensure that components are spaced out sufficiently.

Regular Maintenance and Inspection

Identify and address any signs of thermal stress or damage by performing regular maintenance and inspections. FR4 sheets' lifespan can be extended and further degradation prevented by early detection of issues.

Consider Alternative Materials

For applications that are frequently subjected to high temperatures, investigate alternatives such as ceramic-filled FR4, which provides enhanced thermal resistance while preserving excellent electrical properties.

High-Temperature FR4 Alternatives

Recognizing the need for materials that can withstand higher temperatures, manufacturers have developed high-temperature versions of FR4 sheets. These variants are designed to maintain their properties at elevated temperatures, making them suitable for more demanding applications.

Some high-temperature FR4 alternatives include:

High-Tg FR4

The glass transition temperature of these materials ranges from 170°C to 180°C (338°F to 356°F). This upgraded Tg considers further developed execution in conditions where standard FR4 would fizzle, making them appropriate for applications that experience higher functional temperatures.

Polyimide-based FR4 Sheets

Polyimide-based FR4 sheets are known for their exceptional thermal stability, allowing them to withstand temperatures up to 500°F (260°C). They are therefore ideal for applications requiring maximum heat resistance at extremely high temperatures, such as advanced electronics, the military, and aerospace.

Ceramic-filled FR4

By integrating earthenware fillers into the epoxy sap, these variations accomplish unrivaled temperature opposition. The earthenware components help to keep up with the primary respectability and electrical properties of the FR4 sheets even at raised temperatures, making them reasonable for elite execution and high-unwavering quality applications.

Consider your project's specific temperature requirements when selecting an FR4 sheet for high-temperature applications and select a material that can maintain its properties under those conditions.

Conclusion

While standard FR4 sheets have limitations in high-temperature environments, they remain a versatile and valuable material for many applications. For situations requiring higher temperature resistance, specialized high-temperature FR4 variants are available that can meet more demanding thermal requirements. When considering FR4 sheets for your project, it's crucial to assess the specific temperature conditions the material will be exposed to and choose a variant that can maintain its properties under those conditions. By carefully selecting the right FR4 sheet for your application, you can ensure optimal performance and reliability, even in challenging high-temperature environments.

With over 20 years of experience in production and 10 years in foreign trade, we're well-equipped to help you find the perfect FR4 sheet for your specific needs, whether for standard or high-temperature applications. For more information about our FR4 sheets and other insulating materials, don't hesitate to contact us at info@jhd-material.com.

References

1. "FR4 Material Properties and Usage in Electronics" - PCBWay

2. "High-Temperature Performance of FR4 Laminates" - Isola Group

3. "Understanding Glass Transition Temperature in PCB Materials" - Epec Engineered Technologies

4. "Thermal Management Techniques for High-Temperature PCBs" - Electronics Weekly

5. "Selecting Materials for High-Temperature Electronics" - Advanced Materials