What Is the Use of Phenol in Laminates?

2024-07-18 14:59:02

In laminates, particularly phenolic paper laminates, phenol is a necessary component. The final product's characteristics and functionality are impacted by its presence.This article examines the unique uses of phenol in laminates, highlighting the ways in which it improves their properties and providing justification for its widespread use in the industry.

How Does Phenol Contribute to the Properties of Phenolic Paper Laminate?

The exceptional strength, durability, and resistance to heat and chemicals of phenolic paper laminate are well-known characteristics. The significance of phenol in laminate production can be illuminated by comprehending how phenol shapes these properties.

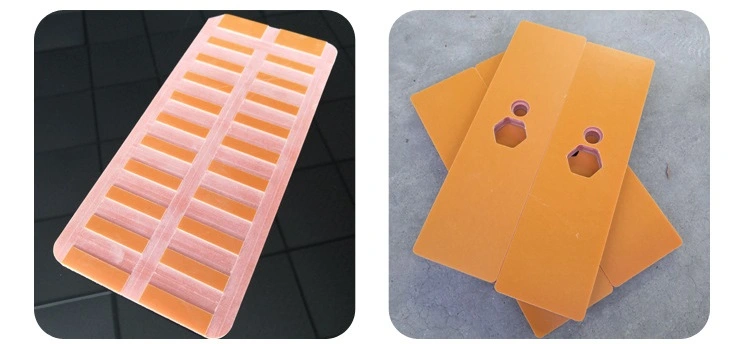

In phenolic paper laminates, phenol is one of the main components of the resin that is used to impregnate the paper layers.

A chemical reaction between formaldehyde and phenol results in the production of phenolic resin during the manufacturing process. A thermostable polymer is produced by this reaction, which is catalyzed by an acidic or alkaline catalyst.

Phenolic pitch goes through a cycle known as cross-connecting when it is warmed up and released from tension. A material that is both durable and rigid is produced as a result of the strong covalent bonds that are formed between polymer chains during this process. The final properties of the laminate, such as its resistance to heat and mechanical strength, are influenced by the degree of cross-linking.

Enhancement of Mechanical Properties The mechanical strength and dimensional stability of phenolic paper laminates are enhanced by the presence of phenolic.

Tensile and flexural strength The laminate's capacity to withstand impact and mechanical stress is enhanced by the inclusion of phenol in the resin matrix. In situations where structural integrity and dependability are of the utmost importance, this strength is crucial.

Due to the cohesive structure created by phenol-based resins, impact resistance is excellent in phenolic laminates. They are suitable for use in environments where the material may be subjected to physical shock or abrasion because of this property.

Phenolic paper laminate is made to be more useful by making it resistant to both chemicals and heat.

Heat-resistant phenolic laminates can withstand high temperatures without deteriorating or deforming significantly. In environments with high temperatures and electrical insulation, as well as in applications where heat is frequently encountered, this heat resistance is absolutely necessary.

Chemical Resistantness Phenolic paper laminate resists a wide range of chemicals, including acids, bases, and solvents. The material's durability and performance in harsh industrial environments are guaranteed by its chemical stability.

The current applications of phenolic paper overlay are hazy.

Due to its unique combination of properties, phenolic paper laminate is utilized in numerous industries.

Phenolic paper laminates are widely used in the electrical and electronic industries due to their significant insulation properties.

Electrical Insulation The material is an excellent electrical insulator, preventing electricity from passing through it and reducing the likelihood of short circuits. It is frequently found in printed circuit boards (PCBs), insulating panels, and components of switchgear.

Electrical structures and high-voltage hardware make use of phenolic covers with a high dielectric strength. The safety and dependability of the electrical infrastructure are guaranteed by its capacity to maintain electrical insulation in extreme conditions.

Automotive and Aerospace The mechanical strength and thermal stability of phenolic paper laminates are advantageous to the automotive and aerospace industries.

Engine Parts Due to their resistance to heat and chemical exposure, phenolic laminates are used in engine parts like gaskets and seals. They increase the longevity and performance of automobile motors by providing effective protection and maintenance.

In aviation applications, phenolic covers are used to cover inside parts that need lightweight, heat-resistant materials. They are suitable for use in aircraft cabinetry, insulation, and panels because they meet aviation safety standards.

The phenolic paper overlay is an essential component in the creation of contemporary hardware and gear.

This material is suitable for bearings, gears, and other components that are subjected to heavy loads and friction due to its mechanical strength and wear resistance. Industrial machinery's durability and effectiveness are enhanced as a result.

Chemical processing plants use phenolic laminates for structural parts and equipment that need to withstand high temperatures and corrosive chemicals. In harsh environments, their chemical resistance ensures safe and dependable operation.

Why is Phenol Preferred Over Other Resins in Laminates?

Phenol is typically used to make laminates because it has distinct advantages over other resin systems.

In terms of heat resistance, polyphenol-based resins perform better than numerous other thermosetting polymers. Due to this property, which ensures that they remain stable and functional at high temperatures, phenolic laminates can be used for electrical insulation and high-temperature environments.

Due to their high dielectric strength and low electrical conductivity, phenolic laminates are excellent insulators for electronic and electrical applications. By preserving the integrity of the insulation and preventing electrical leakage, they enhance the security and dependability of electrical systems.

Phenolic laminates are well-known for their mechanical strength, impact resistance, and dimensional stability. In requesting modern applications, they can endure physical and natural pressure and proposition long haul toughness and constancy.

Phenolic resins can withstand a wide range of chemicals, including solvents, bases, acids, and others. Chemical stability preserves the structural integrity and performance of phenolic laminates while also extending their service life in corrosive environments.

Conclusion

Phenol plays a vital role in the manufacturing of phenolic paper laminate, contributing to its mechanical strength, heat resistance, electrical insulation, and chemical stability. These properties make phenolic laminates indispensable in various industrial applications, including electrical and electronics, automotive, aerospace, and industrial equipment. Phenol's unique characteristics as a resin component ensure that phenolic laminates meet stringent performance requirements, making them a preferred choice for critical applications where reliability and durability are paramount.So Phenol is crucial in phenolic paper laminate manufacturing, enhancing mechanical strength, heat resistance, electrical insulation, and chemical stability. These laminates are vital in industries like electrical, automotive, aerospace, and industrial equipment, meeting rigorous performance standards. Phenol's resin properties ensure reliability and durability, making phenolic laminates preferred for critical applications.

References

1. **Phenolic Resins and Laminates: Chemistry, Properties, and Applications**. (n.d.). Retrieved from [Elsevier](https://www.elsevier.com/books/phenolic-resins-chemistry-applications/brady/978-0-12-369468-3)

2. **Applications of Phenolic Laminates in Electrical Engineering**. (2021). Retrieved from [SpringerLink](https://link.springer.com/chapter/10.1007/978-3-030-50993-0_7)

3. **Phenolic Resins in Automotive Applications**. (2020). Retrieved from [SAE International](https://www.sae.org/publications/technical-papers/content/2020-01-1096/)

4. **Industrial Applications of Phenolic Laminates**. (2022). Retrieved from [Science Direct](https://www.sciencedirect.com/topics/materials-science/phenolic-laminate-applications)