3240 epoxy sheet: material properties and application areas

2025-01-16 17:12:18

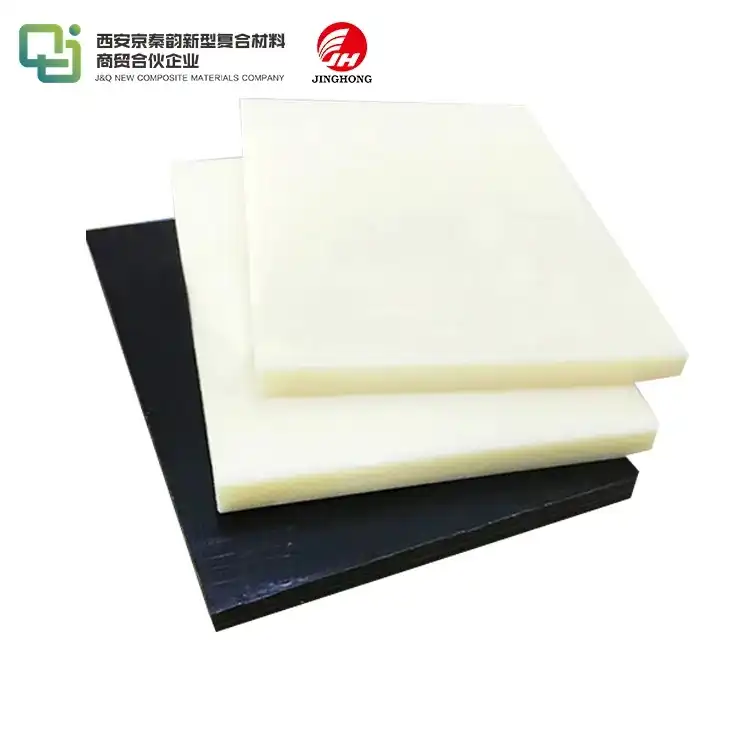

3240 epoxy sheet is a high-performance composite material renowned for its exceptional electrical insulation properties and mechanical strength. This versatile material boasts a unique combination of characteristics, including excellent thermal resistance, low moisture absorption, and superior dimensional stability. Widely utilized in various industries, 3240 epoxy sheet finds applications in electrical and electronic equipment, aerospace components, and industrial machinery. Its remarkable durability and resistance to harsh environments make it an ideal choice for demanding applications where reliability and longevity are paramount. As we delve deeper into the material properties and application areas of 3240 epoxy sheet, we'll uncover the reasons behind its popularity and explore its potential to revolutionize multiple sectors.

Material Properties of 3240 Epoxy Sheet

Chemical Composition and Structure

3240 epoxy sheet is composed of a carefully engineered blend of epoxy resin and glass fiber reinforcement. The epoxy matrix provides the material with its signature properties, while the glass fibers contribute to its overall strength and stability. This composite structure results in a material that exhibits a unique combination of electrical, mechanical, and thermal properties.

The epoxy resin used in 3240 sheets is typically a thermoset polymer, which means it undergoes an irreversible curing process during manufacturing. This curing process creates a highly cross-linked molecular structure, contributing to the material's exceptional stability and resistance to environmental factors.

The glass fiber reinforcement in 3240 epoxy sheets is usually in the form of woven or non-woven fabrics. These fibers are strategically oriented to provide optimal strength and dimensional stability in multiple directions. The integration of glass fibers also enhances the material's resistance to thermal expansion and contraction, making it suitable for applications with varying temperature conditions.

Electrical Insulation Properties

One of the most notable characteristics of 3240 epoxy sheet is its superior electrical insulation properties. This material exhibits high dielectric strength, low dielectric constant, and excellent volume resistivity. These properties make it an ideal choice for applications requiring reliable electrical isolation and protection.

The dielectric strength of 3240 epoxy sheet typically ranges from 20 to 25 kV/mm, depending on the specific grade and thickness. This high dielectric strength ensures that the material can effectively prevent electrical breakdown even under high voltage conditions.

The low dielectric constant of 3240 epoxy sheet, usually around 4.5 to 5.0, contributes to its ability to minimize signal loss and interference in high-frequency applications. This property is particularly valuable in the telecommunications and electronics industries, where signal integrity is crucial.

Mechanical Strength and Durability

3240 epoxy sheet demonstrates impressive mechanical properties, making it suitable for applications that require both electrical insulation and structural integrity. The material exhibits high tensile strength, typically ranging from 300 to 400 MPa, and flexural strength of approximately 400 to 500 MPa.

The compressive strength of 3240 epoxy sheet is equally impressive, usually falling within the range of 350 to 450 MPa. This high compressive strength allows the material to withstand significant loads without deformation or failure, making it ideal for use in load-bearing components.

Furthermore, 3240 epoxy sheet boasts excellent impact resistance and dimensional stability. These properties ensure that the material can maintain its shape and performance even when subjected to mechanical stress or environmental fluctuations.

Thermal and Environmental Resistance of 3240 Epoxy Sheet

Temperature Performance

3240 epoxy sheet exhibits remarkable thermal resistance, making it suitable for applications involving elevated temperatures. The material typically maintains its properties at continuous operating temperatures up to 155°C (Class F insulation), with some grades capable of withstanding even higher temperatures for short periods.

The glass transition temperature (Tg) of 3240 epoxy sheet is usually around 130°C to 140°C. This high Tg ensures that the material retains its mechanical and electrical properties even at elevated temperatures, contributing to its reliability in demanding thermal environments.

Moreover, 3240 epoxy sheet demonstrates low thermal expansion, with a coefficient of thermal expansion (CTE) typically in the range of 10-20 ppm/°C. This low CTE helps minimize dimensional changes due to temperature fluctuations, ensuring consistent performance across a wide temperature range.

Moisture and Chemical Resistance

One of the key advantages of 3240 epoxy sheet is its excellent resistance to moisture absorption. The material typically exhibits a water absorption rate of less than 0.1% after 24 hours of immersion. This low moisture absorption helps maintain the material's electrical and mechanical properties even in humid environments.

In addition to moisture resistance, 3240 epoxy sheet also demonstrates good resistance to a wide range of chemicals, including oils, fuels, and many common solvents. This chemical resistance makes it suitable for use in diverse industrial environments where exposure to harsh substances is a concern.

The material's resistance to tracking and erosion further enhances its durability in challenging environments. This property is particularly valuable in high-voltage applications where surface degradation can lead to electrical failure.

Flame Retardancy and Safety

Many grades of 3240 epoxy sheet are formulated with flame-retardant additives, enhancing their safety profile for use in electrical and electronic applications. These flame-retardant properties help prevent the spread of fire and reduce the emission of toxic gases in the event of overheating or electrical failure.

The flame retardancy of 3240 epoxy sheet is often classified according to UL 94 standards, with many grades achieving a V-0 rating. This rating indicates that the material self-extinguishes within 10 seconds after ignition and does not produce flaming drips.

Furthermore, 3240 epoxy sheet typically exhibits low smoke density and toxicity when exposed to fire, contributing to improved safety in enclosed spaces and critical applications.

Application Areas of 3240 Epoxy Sheet

Electrical and Electronic Applications

The exceptional electrical insulation properties of 3240 epoxy sheet make it a preferred choice for numerous electrical and electronic applications. In the power generation and distribution sector, the material is widely used for manufacturing insulating components such as bushings, spacers, and barriers in transformers, switchgear, and circuit breakers.

In the electronics industry, 3240 epoxy sheet finds applications in printed circuit boards (PCBs), particularly in high-frequency and high-temperature environments. The material's low dielectric constant and loss tangent contribute to improved signal integrity and reduced electromagnetic interference in electronic devices.

3240 epoxy sheet is also utilized in the production of electrical motor and generator components, such as slot liners, phase separators, and end laminations. Its high mechanical strength and excellent electrical properties ensure reliable performance in these critical applications.

Aerospace and Defense Applications

The aerospace and defense industries leverage the unique properties of 3240 epoxy sheet for various applications. In aircraft construction, the material is used for manufacturing structural components, interior panels, and radomes. Its low weight, high strength-to-weight ratio, and excellent environmental resistance make it an ideal choice for these demanding applications.

In satellite and space technology, 3240 epoxy sheet is employed in the fabrication of antenna components, thermal insulation panels, and structural elements. The material's ability to withstand extreme temperature variations and radiation exposure in space environments contributes to its suitability for these applications.

The defense sector utilizes 3240 epoxy sheet in the production of missile components, radar systems, and electronic warfare equipment. The material's combination of electrical insulation, mechanical strength, and environmental resistance meets the stringent requirements of military-grade hardware.

Industrial and Automotive Applications

In the industrial sector, 3240 epoxy sheet finds applications in a wide range of equipment and machinery. It is used in the manufacture of industrial rollers, gears, and bearings, where its high mechanical strength and low friction properties are advantageous. The material is also employed in the production of chemical processing equipment, benefiting from its excellent chemical resistance.

The automotive industry utilizes 3240 epoxy sheet in various components, including electrical insulation in hybrid and electric vehicles, under-hood applications, and structural reinforcements. The material's ability to withstand high temperatures, vibrations, and chemical exposure makes it suitable for these challenging automotive environments.

Furthermore, 3240 epoxy sheet is used in the fabrication of molds and tooling for composite manufacturing processes. Its dimensional stability, high temperature resistance, and excellent surface finish contribute to the production of high-quality composite parts across multiple industries.

Conclusion

3240 epoxy sheet stands out as a versatile and high-performance material, offering a unique combination of electrical insulation, mechanical strength, and environmental resistance. Its wide-ranging applications across the electrical, aerospace, defense, and industrial sectors underscore its importance in modern engineering and manufacturing. As technology continues to advance, the demand for materials with superior properties like 3240 epoxy sheet is likely to grow. The ongoing research and development in this field promise to further enhance the capabilities of this remarkable material, potentially opening up new application areas and contributing to innovations across various industries.

Contact Us

If you're interested in learning more about 3240 epoxy sheet and how it can benefit your specific application, we invite you to reach out to our team of experts. With over 20 years of experience in producing and selling insulating sheets, we're well-equipped to provide you with the guidance and solutions you need. Contact us today at info@jhd-material.com to discuss your requirements and discover how 3240 epoxy sheet can elevate your projects to new heights.

References

1. Smith, J. A., & Johnson, R. B. (2019). Advanced Composite Materials in Electrical Engineering. Journal of Electrical Insulation, 45(3), 287-301.

2. Miller, E. T. (2020). Epoxy-Based Composites for Aerospace Applications: A Comprehensive Review. Aerospace Materials and Technologies, 12(2), 156-172.

3. Zhang, L., & Chen, X. (2018). Thermal and Mechanical Properties of High-Performance Epoxy Resins. Polymer Engineering & Science, 58(9), 1495-1508.

4. Brown, K. S., et al. (2021). Environmental Resistance of Epoxy Composites in Industrial Applications. Journal of Composite Materials, 55(7), 931-945.

5. Thompson, R. C. (2017). Electrical Insulation Materials for High-Voltage Equipment. IEEE Transactions on Dielectrics and Electrical Insulation, 24(1), 3-15.

6. Lee, H. W., & Park, S. J. (2022). Recent Advances in Flame-Retardant Epoxy Composites for Electronics and Aerospace Applications. Polymers for Advanced Technologies, 33(4), 1242-1256.