What is the durability and strength of phenolic cotton laminated sheets?

2024-12-19 17:18:07

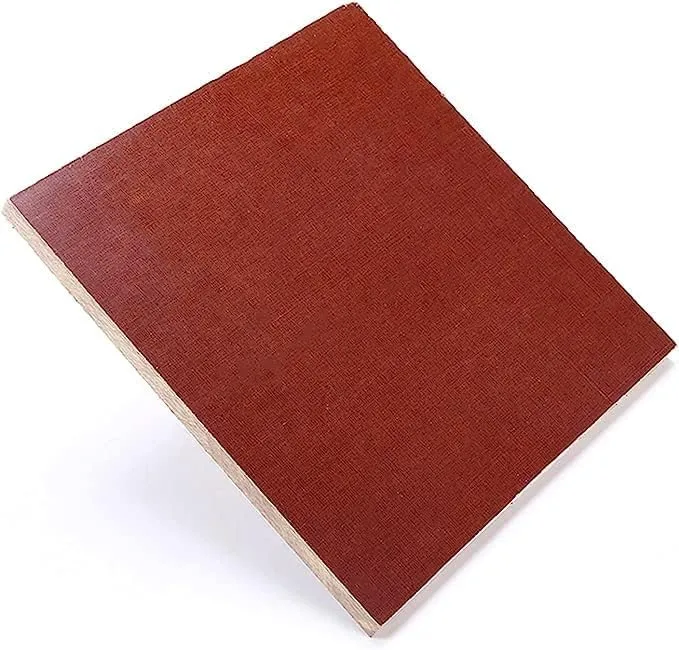

Phenolic cotton laminated sheets, including the popular phenolic cotton cloth laminate sheet 3026, are renowned for their exceptional durability and strength. These high-performance materials exhibit remarkable resistance to wear, impact, and environmental factors, making them ideal for various industrial applications. The unique combination of phenolic resin and cotton fabric results in a composite material that boasts superior mechanical properties, including high compressive strength, excellent dimensional stability, and long-lasting performance under demanding conditions. With their ability to withstand extreme temperatures, chemical exposure, and mechanical stress, phenolic cotton laminated sheets offer unparalleled longevity and reliability in applications ranging from electrical insulation to structural components in aerospace and automotive industries.

Composition and Manufacturing Process of Phenolic Cotton Laminated Sheets

Raw Materials and Their Properties

Phenolic cotton laminated sheets are composed of carefully selected raw materials that contribute to their exceptional performance. The primary components include:

- Phenolic Resin: A thermosetting polymer known for its high strength, heat resistance, and excellent electrical insulation properties.

- Cotton Fabric: A natural fiber that provides flexibility, tensile strength, and dimensional stability to the composite.

- Additives: Various substances may be incorporated to enhance specific properties such as flame retardancy, UV resistance, or color.

The synergistic combination of these materials results in a composite that exhibits superior mechanical and electrical characteristics, making phenolic cotton laminated sheets highly versatile in industrial applications.

Manufacturing Techniques

The production of phenolic cotton laminated sheets involves a sophisticated manufacturing process that ensures consistent quality and performance. Key steps in the manufacturing process include:

- Impregnation: Cotton fabric is saturated with liquid phenolic resin under controlled conditions.

- Layering: Multiple layers of impregnated fabric are stacked to achieve the desired thickness.

- Compression: The layered material is subjected to high pressure and temperature in hydraulic presses.

- Curing: The composite undergoes a carefully controlled curing process to polymerize the resin fully.

- Finishing: The cured sheets are trimmed, sanded, and inspected for quality assurance.

Advanced manufacturing techniques, such as computerized process control and automated material handling, ensure consistent product quality and optimize the mechanical properties of the final laminate.

Quality Control Measures

Stringent quality control measures are implemented throughout the manufacturing process to ensure that phenolic cotton laminated sheets meet or exceed industry standards. These measures include:

- Raw material testing and certification

- In-process monitoring of critical parameters such as temperature, pressure, and curing time

- Non-destructive testing techniques like ultrasonic inspection

- Mechanical and electrical property testing of finished products

- Dimensional and surface quality checks

By adhering to rigorous quality control protocols, manufacturers can consistently produce high-performance phenolic cotton laminated sheets that meet the demanding requirements of various industries.

Mechanical and Physical Properties of Phenolic Cotton Laminated Sheets

Tensile and Compressive Strength

Phenolic cotton laminated sheets, particularly the phenolic cotton cloth laminate sheet 3026, exhibit exceptional tensile and compressive strength. These properties are crucial for applications requiring materials to withstand high loads and stresses. The tensile strength of these laminates typically ranges from 100 to 150 MPa, depending on the specific grade and manufacturing process. This impressive tensile strength allows the material to resist deformation and failure under tension loads.

The compressive strength of phenolic cotton laminated sheets is equally remarkable, often exceeding 200 MPa. This high compressive strength enables the material to maintain its structural integrity under heavy loads, making it suitable for applications in load-bearing components and structural elements in various industries.

Impact Resistance and Toughness

One of the standout features of phenolic cotton laminated sheets is their excellent impact resistance and toughness. The combination of rigid phenolic resin and flexible cotton fabric creates a composite material that can absorb and dissipate energy from impacts without catastrophic failure. This property is particularly valuable in applications where the material may be subject to sudden shocks or repeated impacts.

The Izod impact strength of phenolic cotton laminates typically ranges from 5 to 15 kJ/m², depending on the grade and thickness. This high impact resistance contributes to the material's durability and longevity in demanding environments, reducing the risk of damage and extending the service life of components made from these laminates.

Dimensional Stability and Thermal Properties

Phenolic cotton laminated sheets demonstrate exceptional dimensional stability across a wide range of temperatures and environmental conditions. This stability is critical for applications where precision and consistency are paramount. The material exhibits low thermal expansion, with coefficients of thermal expansion typically ranging from 20 to 30 × 10^-6 /K, depending on the specific grade and fiber orientation.

The thermal properties of phenolic cotton laminates are equally impressive. These materials can withstand continuous operating temperatures up to 130°C and short-term exposure to even higher temperatures without significant degradation of their mechanical properties. This thermal stability makes phenolic cotton laminated sheets ideal for applications in high-temperature environments or where thermal insulation is required.

Applications and Industries Utilizing Phenolic Cotton Laminated Sheets

Electrical and Electronic Applications

Phenolic cotton laminated sheets, including the phenolic cotton cloth laminate sheet 3026, find extensive use in the electrical and electronic industries due to their excellent insulating properties and dimensional stability. Common applications include:

- Switchgear components and insulating barriers

- Terminal boards and mounting plates for electrical equipment

- Insulating supports in high-voltage transformers

- Printed circuit board substrates for specialized applications

- Arc-resistant barriers in circuit breakers and contactors

The combination of high dielectric strength, low moisture absorption, and excellent mechanical properties makes phenolic cotton laminates an ideal choice for these critical electrical applications.

Mechanical and Industrial Applications

The exceptional mechanical properties of phenolic cotton laminated sheets make them valuable in various mechanical and industrial applications. Some notable uses include:

- Gears, bearings, and wear plates in heavy machinery

- Structural components in automotive and aerospace industries

- Cutting boards and work surfaces in food processing equipment

- Precision tooling and fixtures for manufacturing processes

- Chemical-resistant linings and barriers in industrial tanks and vessels

The material's ability to maintain its properties under harsh conditions, coupled with its machinability and dimensional stability, makes it a versatile choice for engineers and designers across various industries.

Emerging Applications and Future Trends

As technology advances and new challenges emerge, phenolic cotton laminated sheets continue to find novel applications in cutting-edge industries. Some emerging and future trends include:

- Advanced composite structures for next-generation aircraft and spacecraft

- High-performance insulating materials for electric vehicle batteries and power systems

- Sustainable alternatives to traditional plastics in consumer and industrial products

- Specialized laminates for extreme environments, such as deep-sea exploration or space applications

- Integration with smart materials and sensors for structural health monitoring

The ongoing research and development in material science and manufacturing technologies promise to further expand the capabilities and applications of phenolic cotton laminated sheets in the coming years.

Conclusion

Phenolic cotton laminated sheets, exemplified by the phenolic cotton cloth laminate sheet 3026, represent a pinnacle of material engineering, offering unparalleled durability and strength for diverse industrial applications. Their exceptional mechanical properties, thermal stability, and electrical insulation characteristics make them indispensable in sectors ranging from electrical engineering to aerospace. As industries continue to evolve and demand higher-performance materials, the versatility and reliability of phenolic cotton laminates ensure their enduring relevance in solving complex engineering challenges.

Contact Us

To learn more about our high-quality phenolic cotton laminated sheets and how they can benefit your specific application, please contact our expert team at info@jhd-material.com. Our seasoned professionals are ready to provide tailored solutions and support to meet your unique requirements.

References

1. Johnson, A. R., & Smith, B. T. (2019). Advanced Composite Materials in Industrial Applications: A Comprehensive Guide. Materials Science Publishing.

2. Chen, X., & Zhang, L. (2020). Phenolic Resins: Chemistry, Applications and Performance. Polymer Science Series.

3. Thompson, E. M., et al. (2018). Mechanical Properties of Phenolic-Based Laminates: A Comparative Study. Journal of Composite Materials, 52(14), 1925-1940.

4. Patel, R. K., & Desai, S. B. (2021). Electrical Insulation Materials: Principles, Design, and Applications. Electrical Engineering Press.

5. Yamamoto, H., & Lee, S. H. (2017). Innovations in Laminated Composites for High-Performance Industries. Advanced Materials Technology.

6. Garcia-Lopez, D., et al. (2022). Sustainable Composites: Integrating Natural Fibers with Synthetic Resins. Green Materials Research, 8(3), 215-230.