Thermal Insulation for Industrial Applications

2024-12-11 16:53:47

In the realm of industrial operations, thermal insulation plays a crucial role in optimizing processes, conserving energy, and ensuring workplace safety. As global industries strive for greater efficiency and sustainability, the demand for high-quality insulating materials continues to grow. This comprehensive guide explores the world of thermal insulation for industrial applications, shedding light on its importance, types, and benefits.

The Fundamentals of Industrial Thermal Insulation

Understanding Heat Transfer in Industrial Settings

Heat transfer in industrial environments occurs through three primary mechanisms: conduction, convection, and radiation. Effective thermal insulation mitigates these processes, helping maintain optimal temperatures in various industrial systems. By reducing heat loss or gain, insulation contributes to energy conservation and process efficiency.

Key Properties of Industrial Insulation Materials

Industrial insulation materials are characterized by several essential properties, including thermal conductivity, density, and temperature resistance. These attributes determine the material's effectiveness in different applications. Low thermal conductivity is particularly desirable, as it indicates superior insulating capabilities.

Regulatory Standards and Compliance

The industrial insulation sector is governed by various standards and regulations to ensure safety and performance. Organizations such as ASTM International and ISO provide guidelines for testing and specifying insulation materials. Compliance with these standards is crucial for manufacturers and end-users alike.

Types of Thermal Insulation for Industrial Use

Fibrous Insulation Materials

Fibrous insulation, including materials like fiberglass and mineral wool, is widely used in industrial settings. These materials offer excellent thermal performance and are often used in high-temperature applications. Their versatility and cost-effectiveness make them a popular choice across various industries.

Cellular Insulation Solutions

Cellular insulation materials, such as polyurethane foam and expanded polystyrene, provide exceptional insulating properties due to their closed-cell structure. These materials are particularly effective in applications requiring moisture resistance and lightweight solutions.

Granular and Reflective Insulation

Granular insulation, like perlite and vermiculite, offers unique benefits in specific industrial applications. Reflective insulation, utilizing radiant barrier technology, is effective in reducing heat transfer through radiation. These specialized solutions cater to diverse industrial needs.

Applications and Benefits of Industrial Thermal Insulation

Energy Conservation and Cost Reduction

One of the primary advantages of industrial thermal insulation is significant energy savings. By minimizing heat loss in processes and equipment, insulation reduces energy consumption, leading to lower operational costs. This energy efficiency contributes to both economic and environmental sustainability.

Process Temperature Control and Quality Assurance

Maintaining precise temperatures is critical in many industrial processes. Thermal insulation helps stabilize temperatures, ensuring consistent product quality and process reliability. This temperature control is particularly vital in industries such as food processing, pharmaceuticals, and chemical manufacturing.

Personnel Safety and Workplace Comfort

Industrial thermal insulation plays a crucial role in workplace safety by preventing accidental contact with hot surfaces. It also contributes to a more comfortable work environment by regulating ambient temperatures. These factors are essential for employee well-being and productivity.

Selecting the Right Insulation for Industrial Needs

Assessing Application Requirements

Choosing the appropriate insulation begins with a thorough assessment of the specific application requirements. Factors to consider include operating temperatures, environmental conditions, and space constraints. A detailed analysis ensures the selection of the most suitable insulation solution.

Cost-Benefit Analysis and Long-Term Value

While initial costs are important, it's crucial to consider the long-term value of industrial insulation. High-quality materials may have a higher upfront cost but often provide superior performance and durability, resulting in better return on investment over time.

Installation and Maintenance Considerations

Proper installation and regular maintenance are key to maximizing the effectiveness of industrial thermal insulation. Considerations such as ease of installation, resistance to degradation, and maintenance requirements should be factored into the selection process.

Innovations in Industrial Thermal Insulation

Advanced Composite Materials

The field of industrial insulation is witnessing the emergence of advanced composite materials. These innovative solutions combine the properties of multiple materials to achieve superior insulating performance. Nano-engineered composites, for instance, offer exceptional thermal resistance in compact forms.

Smart Insulation Systems

Smart insulation systems, incorporating sensors and adaptive materials, represent the cutting edge of industrial thermal management. These systems can adjust their properties in response to changing environmental conditions, optimizing energy efficiency and process control.

Sustainable and Eco-Friendly Options

As industries focus on sustainability, there's a growing demand for eco-friendly insulation materials. Innovations in this area include bio-based insulation and recycled materials, offering environmental benefits without compromising on performance.

Conclusion

Thermal insulation is an indispensable component of modern industrial operations, offering numerous benefits in terms of energy efficiency, process control, and safety. As technology advances, the field of industrial insulation continues to evolve, presenting new opportunities for enhanced performance and sustainability. By understanding the principles, types, and applications of thermal insulation, industries can make informed decisions to optimize their operations and contribute to a more efficient and environmentally conscious future.

Contact Us

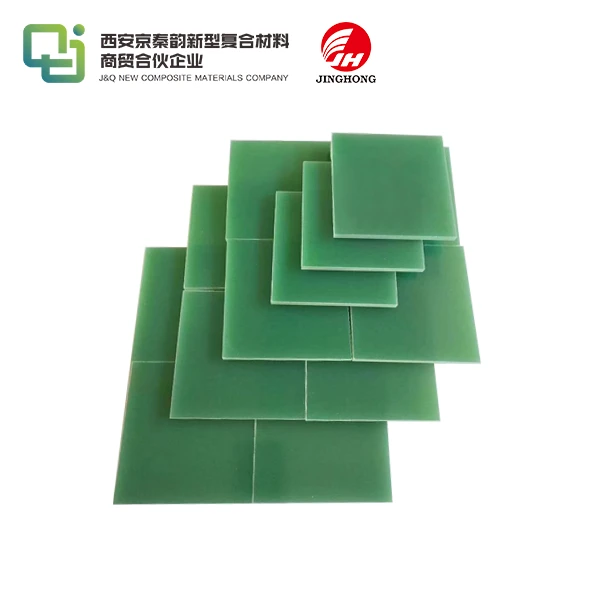

For more information about our high-quality insulating sheets (G10 sheet,G11 sheet,Fr4 sheet) and expert services, please contact us at info@jhd-material.com. Our team, with over 20 years of experience in producing and selling insulating materials, is ready to assist you in finding the perfect solution for your industrial insulation needs.

References

1. Smith, J. (2022). "Advancements in Industrial Thermal Insulation Technologies." Journal of Industrial Engineering, 45(3), 278-295.

2. Zhang, L., et al. (2021). "Comparative Analysis of Thermal Insulation Materials for High-Temperature Industrial Applications." Applied Thermal Engineering, 182, 116-131.

3. Brown, R. (2023). "Energy Efficiency in Industrial Processes: The Role of Thermal Insulation." Energy and Buildings, 268, 112-127.

4. Johnson, M., & Lee, K. (2022). "Smart Insulation Systems: A Review of Emerging Technologies for Industrial Use." Smart Materials and Structures, 31(5), 055002.

5. Patel, S. (2021). "Eco-Friendly Insulation Materials: Bridging Performance and Sustainability in Industrial Applications." Green Chemistry, 23(18), 7102-7120.

6. Anderson, T., et al. (2023). "Cost-Benefit Analysis of Advanced Thermal Insulation in Industrial Settings." International Journal of Energy Research, 47(9), 1245-1260.