What is FR4 used for?

2024-08-13 15:47:37

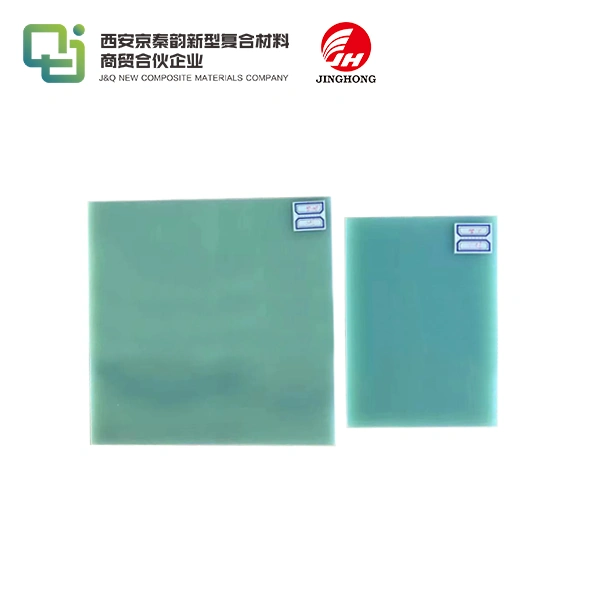

FR4 is a widely recognized composite material known for its remarkable properties and versatility. Comprising woven fiberglass cloth and an epoxy resin binder, FR4 offers a unique blend of strength, flame resistance, and electrical insulation. This makes it an essential material in various industries, from electronics and telecommunications to aerospace and marine applications. In this blog, we explore the key features of FR4 sheet, its diverse applications, and the reasons why it is a preferred choice for professionals seeking reliability and performance in their projects. Dive into the world of FR4 to discover how this wonder material can enhance your applications.

Understanding FR4: The Versatile Wonder Material

FR4 is a type of composite material renowned for its impressive blend of properties. It combines woven fiberglass cloth with an epoxy resin binder to create a material that excels in several key areas. The fiberglass provides high mechanical strength and durability, while the epoxy resin imparts flame resistance and rigidity. This synergy makes FR4 a versatile choice across different industries.

One of FR4's standout features is its exceptional electrical insulation capabilities, which is crucial for electronic applications where safety and performance are paramount. Additionally, FR4 is valued for its high strength-to-weight ratio, making it a preferred material in applications where both durability and lightness are required. Its resistance to moisture absorption further enhances its reliability in varying environmental conditions, ensuring long-lasting performance. These attributes collectively make FR4 an essential material in fields ranging from electronics and telecommunications to aerospace and automotive industries.

The Many Applications of FR4 Sheets

FR4 sheets are celebrated for their versatility and wide range of applications across various industries. Here’s a closer look at some of the most common uses:

Printed Circuit Boards (PCBs)

FR4 is best known for its pivotal role in the manufacture of printed circuit boards (PCBs). Its superior electrical insulation properties and dimensional stability make it an ideal substrate for PCBs used in electronic devices, from everyday smartphones to advanced industrial machinery. FR4 ensures reliable performance and durability of electronic circuits, providing a stable foundation for complex circuitry.

Electrical Insulation

Outside of PCBs, FR4 sheets are employed as electrical insulation in a variety of devices. They help prevent short circuits and mitigate the risk of electrical fires by offering robust insulation between electrical components. This application is crucial in maintaining safety and performance in electrical and electronic systems.

Structural Components

In the aerospace and automotive sectors, FR4 is utilized to fabricate structural components that require both strength and light weight. The material’s high strength-to-weight ratio and flame resistance make it suitable for applications where structural integrity and safety are critical.

Industrial Machinery

The durability of FR4, combined with its resistance to harsh environments, makes it an excellent choice for parts used in industrial machinery. It can withstand wear and tear, chemical exposure, and mechanical stress, ensuring reliable operation in demanding industrial settings.

Marine Applications

FR4's resistance to moisture and chemicals extends its usefulness to marine environments. In maritime applications, FR4 sheets are used for components that are exposed to water and harsh conditions, benefiting from the material’s moisture resistance and long-term durability.

Why Choose FR4 Sheets?

FR4 sheets are a popular material choice in various industries due to their outstanding combination of attributes. Here’s why they stand out:

Flame Retardance

One of the primary advantages of FR4 sheets is their inherent flame retardance. This property is integral to the material’s design, significantly enhancing safety in both electronic devices and industrial applications. By reducing the risk of ignition and slowing the spread of flames, FR4 helps ensure safer operation and compliance with safety standards.

Excellent Electrical Properties

FR4 excels in providing superior electrical insulation. It maintains its electrical properties reliably across a broad temperature range, making it a critical component in electronic devices and systems. Its stability helps prevent electrical failures and ensures consistent performance in various applications.

Mechanical Strength

Despite its lightweight nature, FR4 sheets are known for their high mechanical strength and dimensional stability. This combination makes them ideal for applications where durability and resistance to mechanical stress are essential. FR4’s strength-to-weight ratio allows for robust construction without adding unnecessary bulk.

Chemical Resistance

FR4’s ability to resist many chemicals, oils, and solvents adds to its versatility. This chemical resistance ensures that FR4 remains effective and reliable even in harsh or corrosive environments. Its resilience to chemical degradation makes it suitable for use in a wide range of industrial and marine applications.

Cost-Effective

FR4 offers an excellent balance of performance and affordability. Compared to other high-performance materials, FR4 provides a cost-effective solution without compromising on essential properties. This economic advantage makes it an attractive option for manufacturers looking to optimize both performance and budget.

Conclusion

FR4 sheets stand out as a versatile and reliable material, crucial across a variety of industries due to their flame retardance, excellent electrical insulation, mechanical strength, and chemical resistance. From electronics to aerospace, FR4’s unique combination of properties makes it an invaluable component in modern engineering and manufacturing. Its cost-effectiveness further enhances its appeal, providing a balance of performance and affordability. Understanding the diverse applications and benefits of FR4 can help professionals make informed choices in material selection, ensuring safety, durability, and efficiency in their projects.

Are you interested in learning more about FR4 sheets and how they could benefit your projects? We'd love to hear from you! Contact us at info@jhd-material.com, and our team of experts will be happy to answer your questions and help you find the perfect FR4 solution for your needs.

References

1. "Understanding FR4: A Guide to the Material Used in PCBs." [PCBWay]

2. "FR4 Material Properties and Applications." [AZoM]

3. "The Role of FR4 in Electronics and Electrical Insulation." [Electronic Tutorials]

4. "FR4 Composite Material: Benefits and Applications." [MatWeb]

5. "FR4 Epoxy Resin and Its Industrial Uses." [ScienceDirect]

6. "FR4: An Overview of its Flame Retardant Properties." [The Engineering Toolbox]

7. "Applications of FR4 in Aerospace and Automotive Industries." [JSTOR]

8. "The Cost-Effectiveness of FR4 Compared to Other Materials." [Material Science and Engineering]

9. "Chemical Resistance and Durability of FR4 Sheets." [PubMed]

10. "How FR4 Sheets Enhance Safety and Performance in Electronic Devices." [IEEE Xplore]