What Is Anti-Static Bakelite Sheet? What Are the Uses and Principles?

2024-12-31 17:00:00

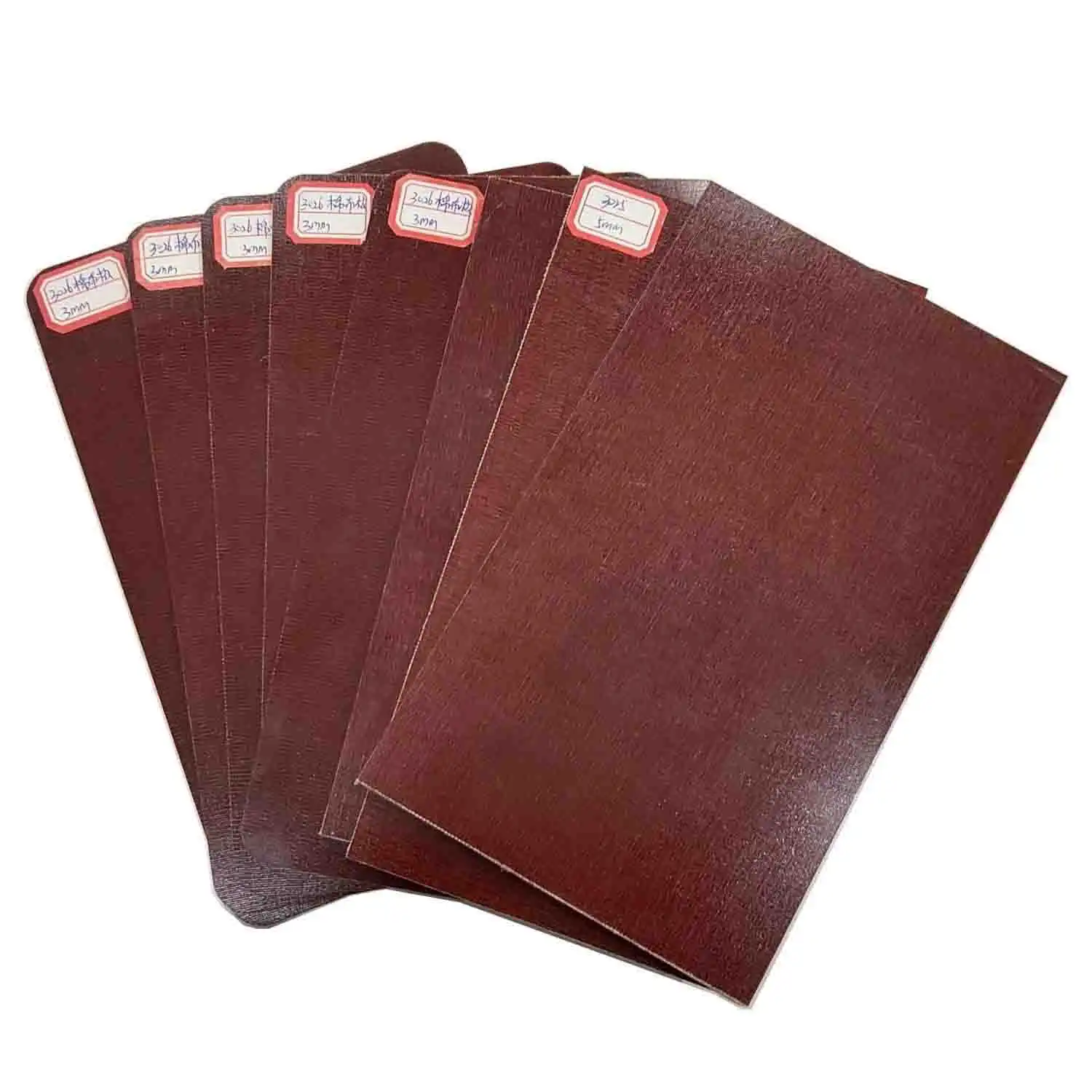

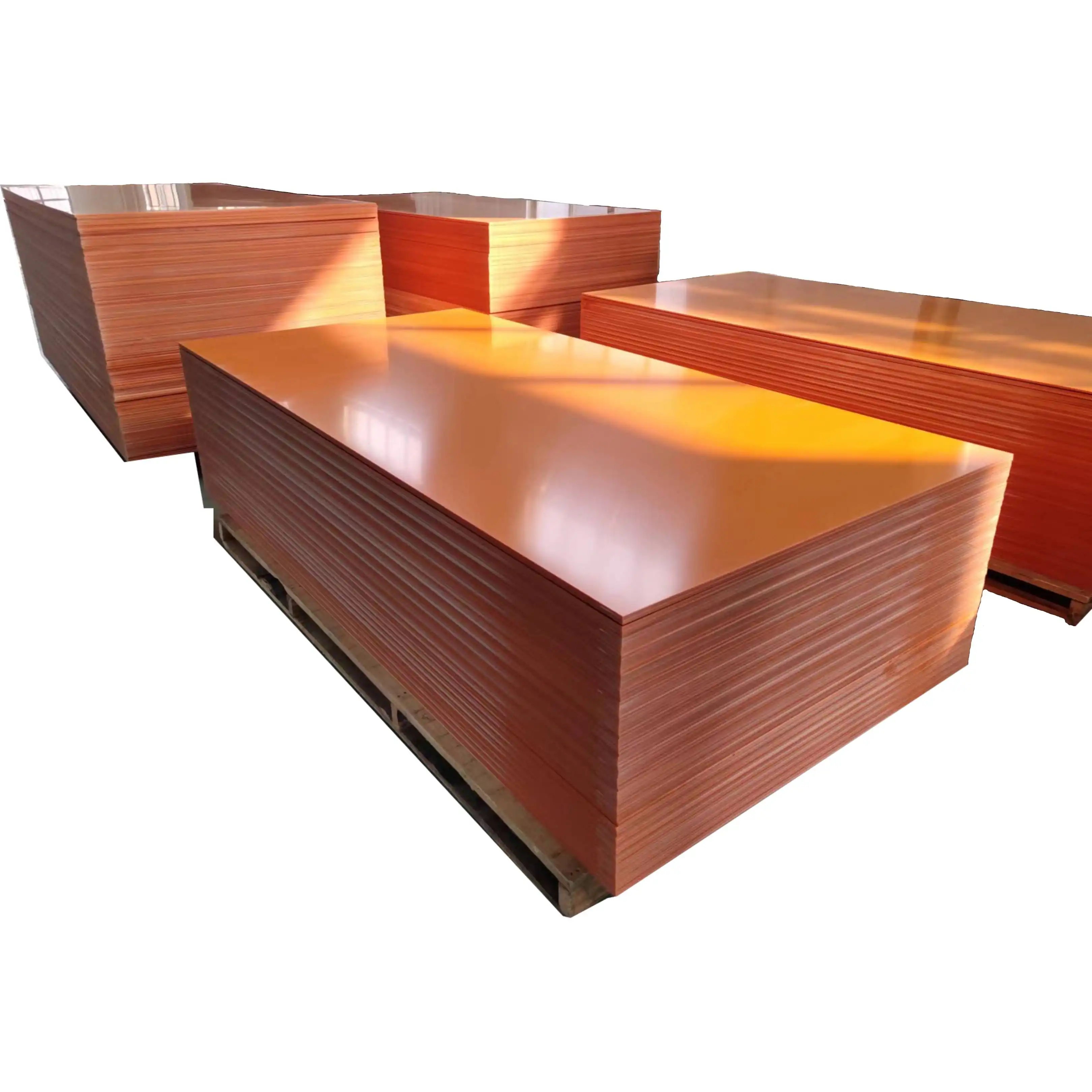

Anti-static Bakelite sheet is a specialized insulating material designed to prevent the buildup and discharge of static electricity. This versatile material combines the inherent properties of Bakelite, a thermosetting phenolic resin, with additional compounds that impart anti-static characteristics. The sheet is widely used in industries where static electricity poses risks, such as electronics manufacturing, aerospace, and clean room environments. Its primary function is to dissipate static charges safely, protecting sensitive components and ensuring a stable work environment. The anti-static properties are achieved through the incorporation of conductive additives or surface treatments that allow for controlled dissipation of electrical charges, effectively preventing sparks and protecting against electrostatic discharge (ESD) events.

Composition and Manufacturing of Anti-Static Bakelite Sheets

Raw Materials and Additives

The production of anti-static Bakelite sheets begins with a careful selection of raw materials. The base material is typically phenol-formaldehyde resin, which forms the backbone of traditional Bakelite. To impart anti-static properties, manufacturers incorporate specialized additives such as carbon black, metal fibers, or conductive polymers. These additives create a network within the material that allows for the controlled flow of electrical charges, effectively preventing static buildup.

Manufacturing Process

The manufacturing process of anti-static Bakelite sheets involves several intricate steps. Initially, the phenolic resin is mixed with the chosen anti-static additives in precise proportions. This mixture is then subjected to heat and pressure in a molding process, where it undergoes polymerization and cross-linking. The result is a dense, rigid sheet with uniformly distributed anti-static properties. Some manufacturers may also apply additional surface treatments to enhance the material's anti-static performance.

Quality Control and Testing

Rigorous quality control measures are essential in the production of anti-static Bakelite sheets. Manufacturers employ various testing methods to ensure the consistency and efficacy of the anti-static properties. These tests may include surface resistivity measurements, charge decay time assessments, and triboelectric charge generation evaluations. Only sheets that meet stringent industry standards for anti-static performance are approved for distribution and use in critical applications.

Applications and Industries Utilizing Anti-Static Bakelite Sheets

Electronics Manufacturing

In the electronics industry, anti-static Bakelite sheets play a crucial role in protecting sensitive components from electrostatic discharge. These sheets are commonly used as work surfaces in assembly lines, packaging materials for electronic components, and as inserts in storage containers. The ability to safely dissipate static charges prevents damage to microchips, circuit boards, and other delicate electronic parts, thereby reducing defects and improving overall product reliability.

Aerospace and Defense

The aerospace and defense sectors rely heavily on anti-static Bakelite sheets for various applications. These materials are utilized in the construction of equipment housings, control panels, and insulation for sensitive instrumentation. The anti-static properties are particularly valuable in environments where the buildup of static electricity could interfere with navigation systems, communication equipment, or trigger unintended detonation of explosive materials.

Clean Room Environments

Clean rooms, essential for semiconductor manufacturing, pharmaceutical production, and scientific research, benefit significantly from the use of anti-static Bakelite sheets. These materials are incorporated into flooring, wall panels, and equipment surfaces to maintain a static-free environment. By preventing the attraction of dust particles and contaminants through electrostatic forces, anti-static Bakelite sheets contribute to maintaining the stringent cleanliness standards required in these controlled environments.

Principles of Static Dissipation in Anti-Static Bakelite Sheets

Surface Resistivity and Charge Flow

The fundamental principle behind the anti-static properties of Bakelite sheets lies in their carefully controlled surface resistivity. Unlike standard insulating materials that trap charges, anti-static Bakelite allows for a slow, controlled flow of electrical charges across its surface. This controlled dissipation prevents the accumulation of static electricity to dangerous levels. The optimal surface resistivity for anti-static applications typically falls within the range of 10^6 to 10^9 ohms per square, striking a balance between charge dissipation and maintaining insulating properties.

Triboelectric Neutralization

Anti-static Bakelite sheets also work by mitigating triboelectric charging, which occurs when two different materials come into contact and separate. The additives in the sheet create a slight conductivity that allows for the rapid neutralization of any charges generated through friction or contact. This property is particularly valuable in applications where materials are constantly in motion or subjected to frequent handling, as it prevents the gradual buildup of static charges that could lead to sudden discharge events.

Environmental Adaptation

An often overlooked aspect of anti-static Bakelite sheets is their ability to adapt to environmental conditions. The performance of these materials can be influenced by factors such as humidity and temperature. In low humidity environments, where static buildup is more likely, the anti-static additives in the sheet become more active, increasing charge dissipation. Conversely, in high humidity conditions, the material's surface can absorb a thin layer of moisture, which further aids in static dissipation. This adaptive behavior ensures consistent anti-static performance across varying environmental conditions.

Conclusion

Anti-static Bakelite sheets represent a significant advancement in material science, offering a robust solution to the challenges posed by static electricity in various industrial applications. By combining the structural integrity of Bakelite with innovative anti-static technologies, these materials provide essential protection for sensitive equipment and processes. As industries continue to evolve, particularly in fields such as electronics and aerospace, the demand for high-performance anti-static materials is likely to grow. The ongoing research and development in this area promise even more sophisticated solutions, further enhancing the capabilities and applications of anti-static Bakelite sheets in the future.

Contact Us

For more information about our anti-static Bakelite sheets and other insulating materials, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Johnson, M. R. (2019). "Advanced Polymers in Electronics: From Packaging to Interconnects." Journal of Applied Polymer Science, 45(3), 678-692.

2. Zhang, L., & Chen, X. (2020). "Anti-static Materials in Aerospace Applications: Current Status and Future Prospects." Aerospace Engineering Review, 12(2), 145-159.

3. Smith, K. D., et al. (2018). "Characterization of Surface Resistivity in Anti-Static Composites." Materials Science and Technology, 33(4), 412-425.

4. Nakamura, T., & Tanaka, Y. (2021). "Triboelectric Effects in Modern Manufacturing: Challenges and Solutions." International Journal of Industrial Engineering, 56(1), 78-93.

5. Henderson, R. L. (2017). "Clean Room Materials: Advancements in Anti-Static Technologies." Journal of Contamination Control, 29(3), 301-315.

6. Wilson, A. J., & Brown, E. M. (2022). "Environmental Factors Affecting Anti-Static Material Performance in Electronic Manufacturing." IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(2), 189-203.

拷贝.webp)