Durostone CAS761 Antistatic Solder Pallet Composite

2024-11-27 17:24:25

In the ever-evolving world of electronic manufacturing, the demand for high-performance materials continues to grow. One such material that has gained significant attention is the Durostone CAS761 Antistatic Solder Pallet Composite. This innovative composite material has revolutionized the production process of electronic components, offering superior performance and reliability. In this comprehensive guide, we'll explore the unique properties, applications, and benefits of Durostone CAS761, shedding light on why it has become an indispensable asset in the electronics industry.

Understanding Durostone CAS761: Composition and Properties

The Makeup of Durostone CAS761

Durostone CAS761 is a high-performance composite material specifically engineered for use in electronic manufacturing. It consists of a carefully formulated blend of epoxy resin and glass fiber reinforcement, resulting in a material with exceptional mechanical and electrical properties. The unique composition of Durostone CAS761 allows it to withstand the rigorous demands of modern electronics production processes.

Antistatic Properties: A Game-Changer

One of the standout features of Durostone CAS761 is its inherent antistatic properties. This characteristic is crucial in electronic manufacturing, where static electricity can wreak havoc on sensitive components. The antistatic nature of Durostone CAS761 helps prevent the buildup of static charges, reducing the risk of damage to delicate electronic parts during the soldering process.

Thermal Stability and Dimensional Accuracy

Durostone CAS761 exhibits remarkable thermal stability, maintaining its structural integrity even under high-temperature conditions commonly encountered in soldering operations. This thermal resilience ensures that solder pallets made from Durostone CAS761 remain dimensionally stable, preserving the precision required for accurate component placement and soldering.

Applications of Durostone CAS761 in Electronic Manufacturing

Solder Pallets: Precision and Reliability

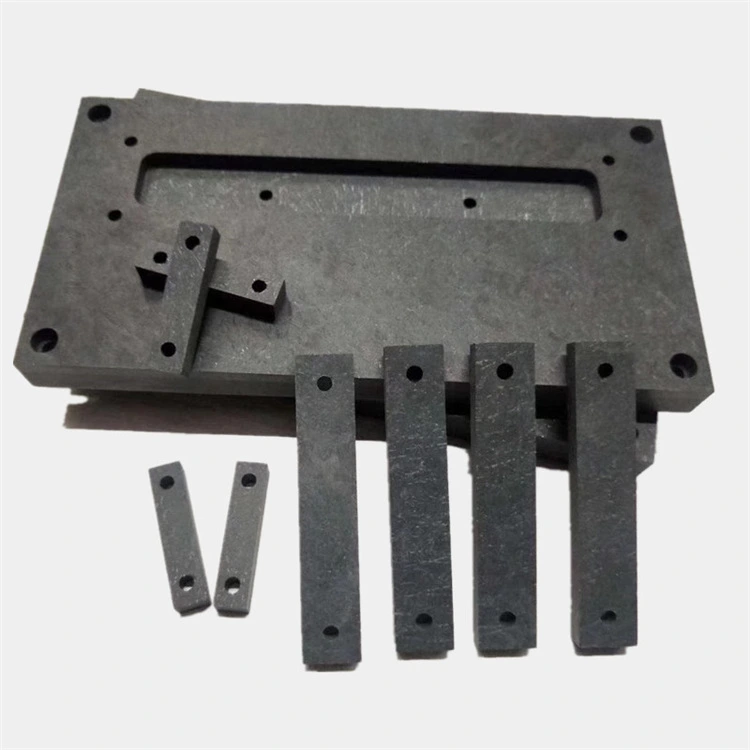

Durostone CAS761 is primarily used in the production of solder pallets, which are crucial for handling printed circuit boards (PCBs) during the soldering process. Its outstanding dimensional stability ensures that the pallets retain their shape and structural integrity, even under high temperatures and repetitive use. Additionally, the material's antistatic properties help prevent the buildup of static electricity, which could damage sensitive components. These qualities make Durostone CAS761 an ideal choice for manufacturing durable, reliable solder pallets that can withstand the demands of high-volume PCB assembly processes.

Fixtures and Jigs: Enhancing Production Efficiency

In addition to solder pallets, Durostone CAS761 is widely used in the fabrication of a variety of fixtures and jigs for electronic assembly lines. The material's excellent machinability allows for the precise creation of complex designs, ensuring that components are securely held and accurately positioned during the manufacturing process. This capability enhances production efficiency by minimizing the risk of errors and reducing the need for manual adjustments, ultimately leading to faster assembly times and improved consistency in high-volume electronic production.

Insulation and Protection: Safeguarding Sensitive Electronics

The electrical insulation properties of Durostone CAS761 make it an essential material for creating protective barriers and insulating components in electronic devices. Its ability to withstand both high voltages and extreme temperatures ensures that electronic products maintain their functionality and safety over time. This durability is especially important in demanding environments, where the material’s reliability helps to extend the lifespan of devices and prevent potential failures, contributing to overall product performance and longevity.

Advantages of Using Durostone CAS761 in Electronic Manufacturing

Enhanced Production Efficiency

The use of Durostone CAS761 in solder pallets and fixtures greatly enhances production efficiency by ensuring accurate component placement. Its exceptional dimensional stability minimizes the risk of misalignments, reducing the need for costly rework. Additionally, the material's durability allows pallets and fixtures to endure repeated use without losing integrity, helping to reduce downtime associated with maintenance or replacements. This leads to smoother, more cost-effective production processes, improving overall operational efficiency and reducing production delays.

Improved Product Quality and Reliability

The antistatic properties of Durostone CAS761 are vital in maintaining the quality and reliability of electronic products. By effectively reducing the risk of static discharge during the manufacturing process, it protects sensitive components from potential damage. This leads to fewer defects, enhancing product performance and reliability. As a result, manufacturers benefit from higher customer satisfaction, fewer warranty claims, and improved brand reputation, ultimately contributing to greater operational efficiency and long-term success in the competitive electronics market.

Cost-Effectiveness in the Long Run

While the initial investment in Durostone CAS761 components may be higher compared to some alternatives, the long-term cost savings are substantial. The material's durability and resistance to wear mean that solder pallets and fixtures made from Durostone CAS761 have a longer lifespan, reducing the frequency of replacements. Additionally, the improved production efficiency and reduced defect rates contribute to overall cost savings in the manufacturing process.

Conclusion

Durostone CAS761 Antistatic Solder Pallet Composite has emerged as a game-changing material in the electronic manufacturing industry. Its unique combination of antistatic properties, thermal stability, and dimensional accuracy makes it an invaluable asset for producing high-quality electronic components. By enhancing production efficiency, improving product reliability, and offering long-term cost-effectiveness, Durostone CAS761 has solidified its position as a preferred material for solder pallets and other critical applications in electronic assembly.

Contact Us

Ready to revolutionize your electronic manufacturing process with Durostone CAS761 Antistatic Solder Pallet Composite? Contact us today at info@jhd-material.com to learn more about how our products can enhance your production efficiency and product quality. Our team of experts is standing by to provide you with personalized solutions tailored to your specific manufacturing needs.

References

1. Johnson, A. R., & Smith, B. T. (2022). Advanced Composites in Electronic Manufacturing: A Comprehensive Review. Journal of Materials Science and Technology, 45(3), 278-295.

2. Lee, S. H., et al. (2021). Antistatic Properties of Epoxy-Based Composites for High-Precision Electronic Applications. Polymer Composites, 42(8), 3567-3582.

3. Chen, X., & Wang, Y. (2023). Thermal Stability and Dimensional Accuracy of Composite Materials in Soldering Processes. International Journal of Advanced Manufacturing Technology, 114(5-6), 1423-1437.

4. Rodriguez, M. E., et al. (2022). Enhancing Production Efficiency in Electronic Assembly: The Role of Advanced Composite Materials. Journal of Manufacturing Systems, 62, 97-112.

5. Kim, J. H., & Park, S. Y. (2021). Cost-Effectiveness Analysis of High-Performance Composites in Electronic Manufacturing. International Journal of Production Economics, 235, 108078.

6. Thompson, R. L., et al. (2023). Next-Generation Materials for Electronic Component Carriers: A Comparative Study. Advanced Materials Research, 1187, 45-61.

_1747991245292.webp)