What is an FR4 Epoxy Sheet?

2024-06-14 11:57:22

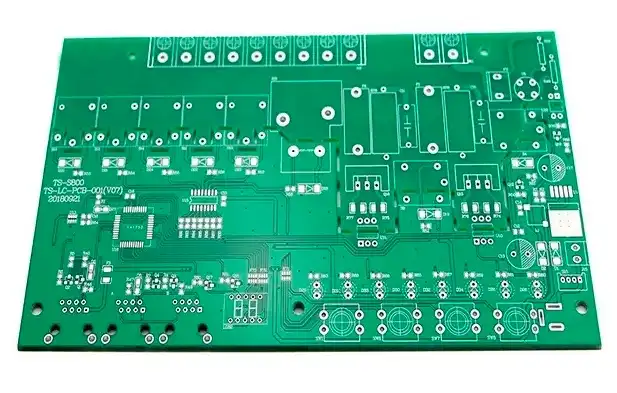

Flame Resistance FR4 Fiber Glass Laminate Sheet is a type of composite material primarily used in the electronics industry for printed circuit boards (PCBs) and as an insulator in various applications. Its main components are woven fiberglass and an epoxy resin binder, making it flame retardant and highly resistant to electrical and mechanical stress.

This material's fire retardant properties are significant in applications where fire security is vital. The nearness of epoxy tar not as it were improves its mechanical quality but too contributes to its capacity to withstand tall temperatures without debasing or transmitting destructive exhaust. This makes FR4 an perfect choice for utilize in shopper hardware, such as tvs and computers, where security controls require materials to hinder fire propagation.

Furthermore, FR4's amazing dimensional solidness beneath warm stretch is a critical advantage in exactness applications. This steadiness guarantees that the measurements of the PCBs stay reliable, indeed beneath shifting warm conditions, which is basic for keeping up the judgment of electrical associations and the by and large usefulness of electronic gadgets. Its flexibility and unwavering quality proceed to make FR4 a prevalent choice among engineers and architects in the hardware industry.

Understanding FR4's Composition and Properties

Flame Resistance FR4 Fiber Glass Laminate Sheet is composed of a woven fiberglass cloth impregnated with an epoxy gum cover. This composition gives FR4 its fundamental characteristics, such as tall mechanical quality, fabulous electrical cover, and great chemical and dampness resistance. The fabric too highlights a striking fire retardancy, with a combustibility rating of 94V-0, showing that it stops burning inside 10 seconds on a vertical example; dribbles of particles, if any, cannot be ignited.

Typical Employments and Applications

The essential utilize of FR4 is in the make of PCBs, where it gives auxiliary judgment as well as electrical separator between copper layers. FR4's great warm properties make it appropriate for high-power and high-speed electronic circuits. Aside from hardware, FR4 is utilized in different basic applications requiring tall affect resistance and toughness.

Past gadgets and auxiliary employments, FR4 finds applications in the aviation industry due to its light weight and resistance to fire, dampness, and different chemicals. These properties make it perfect for utilize in the insides boards and components of airplane where security and solidness are basic. Also, its cover capabilities are utilized in both the cockpit and traveler compartments to protect against electrical and warm hazards.

Furthermore, Flame Resistance FR4 Fiber Glass Laminate Sheet is progressively being utilized in the car industry. Its warm resistance and auxiliary quality are advantageous for under-the-hood applications, counting electric vehicle battery walled in areas and control frameworks. The material's versatility to tall temperatures and unforgiving situations makes a difference in expanding the life expectancy of car components, which is pivotal as the industry shifts towards more maintainable and long-lasting products.

Mechanical and Warm Properties

FR4 sheets display strong mechanical properties such as malleable quality extending from 38,000 to 45,000 psi and compressive quality of around 65,000 psi. Its flexural quality can reach up to 75,000 psi, exhibiting its capacity to stand up to misshapening beneath stack. Thermally, FR4 can withstand ceaseless working temperatures of almost 130°C (266°F) to 140°C (284°F), which makes it reasonable for different mechanical applications.

Electrical Characteristics

FR4's electrical protection properties are vital for its utilize in PCBs. It has a dielectric quality of 20 MV/m, which makes a difference anticipate electrical breakdowns in circuits. The material's dielectric steady is around 4.4, which is reasonable for numerous electrical and electronic applications but may not be perfect for high-frequency or exactness applications where a steady dielectric steady is required.

Advantages Over Other Materials

Compared to other materials like high-frequency laminates, Flame Resistance FR4 Fiber Glass Laminate Sheet is generally more cost-effective and sufficient for a broad range of applications that do not require extremely low dielectric constant variability with temperature changes. However, for applications demanding high precision and thermal stability, materials specifically designed for high-frequency applications may be preferable.

FR4 also offers excellent mechanical strength and resistance to moisture, making it a robust choice for many environmental conditions where other materials might degrade or perform inconsistently. This durability extends the life of products and reduces maintenance and replacement costs, which is a significant advantage in sectors like consumer electronics and industrial machinery.

In addition to these benefits, FR4 is easy to fabricate and machine, which allows for more complex designs and rapid production cycles. This ease of manufacturing makes it an attractive option for startups and established companies alike, facilitating quick turnarounds in product development and testing. Such versatility is less common in more specialized materials, which may require more sophisticated processing techniques and equipment.

Contact Us

As a professional manufacturing supplier, we pride ourselves on offering top-quality Flame Resistance FR4 Fiber Glass Laminate Sheet alongside comprehensive services. Our GMP-certified factory maintains a large inventory, ensuring quick delivery of bulk and custom orders. We support OEM requests, provide tight and secure packaging, and all products come with complete certifications. Our technical support and testing services are designed to meet the needs of global buyers looking for reliable and long-term cooperation. Feel free to reach out at info@jhd-material.com for any inquiries or partnership opportunities.