What is an Epoxy Glass Fiber Sheet?

2024-06-18

Introduction

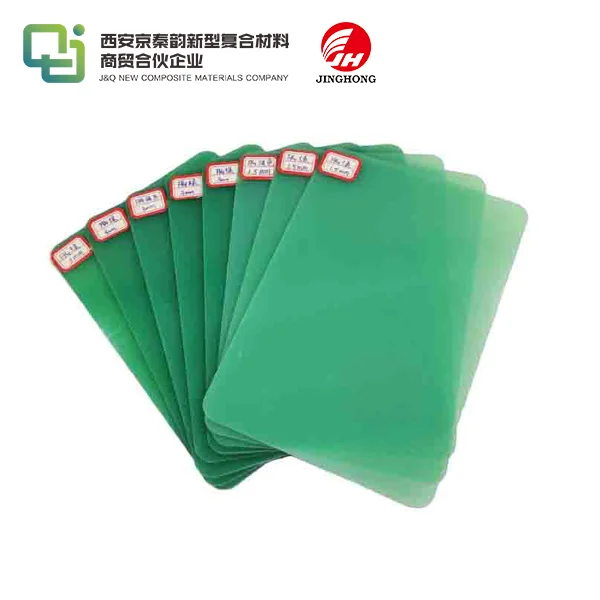

Epoxy Resin Sheets, commonly known by names such as G10 and FR-4, are materials composed of woven fiberglass cloth impregnated with an epoxy resin. These materials are known for their excellent mechanical strength, electrical insulation properties, and durability. They are widely used in various industries, including electronics, automotive, and aerospace.

Composition and Manufacturing

Epoxy glass fiber sheets, usually known as FR4, are made out of a blend of epoxy sap and glass strands. The assembling system starts with the impregnation of glass fiber mats or fabric with epoxy tar, which fills in as a folio and gives mechanical strength and electrical protection. The impregnated material is then relieved under intensity and strain to make a strong composite sheet.

The epoxy pitch, ordinarily obtained from bisphenol A (BPA) and epichlorohydrin, offers a phenomenal bond to the glass strands and furnishes the sheet with substance opposition, mechanical strength, and layered dependability. Also, epoxy tars display high dielectric properties, making them reasonable for electrical applications.

The glass strands, frequently as woven mats or ceaseless rovings, build up the epoxy pitch, giving rigidity, influence opposition, and layered dependability to the composite sheet. The direction and thickness of the glass strands can be custom-fitted to accomplish explicit mechanical and electrical properties in the end result.

During the assembling system, the impregnated material is stacked in layers and afterward restored involving intensity and strain in a cycle known as overlay. This guarantees legitimate holding between the epoxy sap and the glass strands, bringing about a uniform and strong composite material.

Key Properties

Epoxy Glass Fiber Sheets, otherwise called FR4, display a few key properties that make them appropriate for a great many applications. Right off the bat, they offer amazing mechanical strength and layered steadiness, making them reasonable for use in primary parts, printed circuit sheets (PCBs), and different applications requiring strong materials. The support given by the glass strands upgrades the general strength of the composite material.

Also, epoxy glass fiber sheets have high dielectric strength and magnificent electrical protection properties, which are fundamental for applications in electrical and electronic hardware, where keeping up with protection trustworthiness is vital for security and execution.

Additionally, these sheets show great compound opposition, especially to solvents, powers, and different natural variables, adding to their strength and long-haul unwavering quality in testing working circumstances.

Besides, epoxy glass fiber sheets are fit for enduring raised temperatures, making them reasonable for use in applications where warm soundness is fundamental. They likewise show low water assimilation, which keeps up with their electrical and mechanical properties in muggy or wet conditions.

The layered strength of epoxy glass fiber sheets guarantees that they keep up with their shape and mechanical properties over the long run, much under changing natural circumstances.

Common Uses and Applications

Epoxy Resin Sheets regularly alluded to as FR4, track down broad use across different ventures because of their adaptable properties. One of the essential applications is in the assembling of printed circuit sheets (PCBs). FR4 sheets act as the substrate for PCBs, offering mechanical help and electrical protection for the many-sided hardware. Their amazing dielectric strength and layered steadiness make them ideal for this reason.

In the airplane business, epoxy glass fiber sheets are used in the manufacture of underlying parts for airplanes and shuttles. Their blend of high strength, lightweight, and protection from temperature changes makes them reasonable for applications like inside boards, fairings, and radomes.

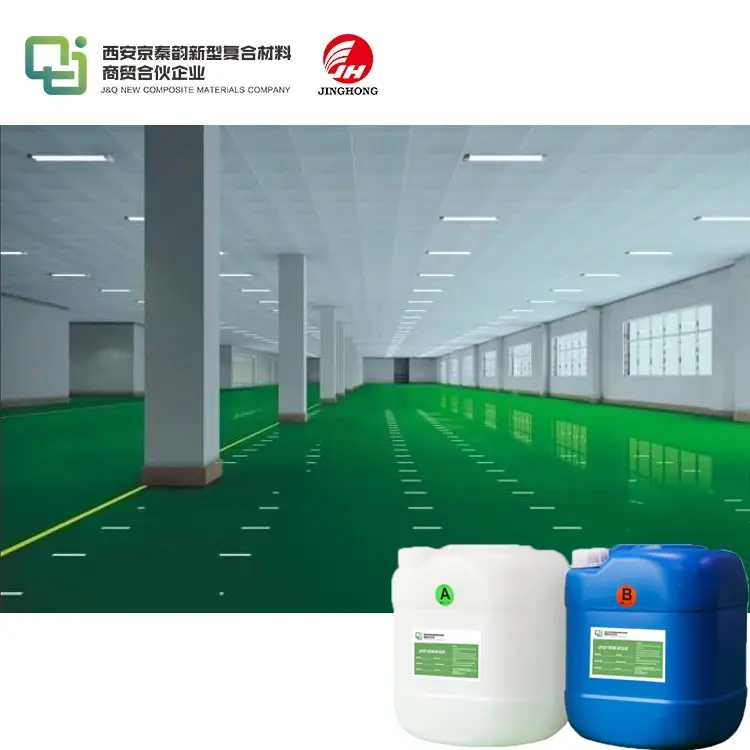

Additionally, FR4 sheets are generally utilized in electrical and electronic gear, including transformers, protectors, and switchgear. Their predominant electrical protection properties assist with forestalling electrical breakdowns and guarantee the protected and solid activity of such gadgets.

The auto business likewise uses epoxy glass fiber sheets in different applications, like motor parts, engine protection, and inside boards. Their capacity to endure high temperatures and openness to synthetic compounds makes them reasonable for these requesting conditions.

Furthermore, FR4 sheets are utilized in the development and assembling of modern gear, where they act as protection boundaries, underlying scaffoldings, and defensive nooks. Their sturdiness, substance obstruction, and warm security make them appropriate for these applications.

Comparison with Other Materials

Epoxy Glass Fiber Sheets offer a few benefits over elective materials, making them a favored decision for different applications. Contrasted with conventional materials like metal or plastic, epoxy glass fiber sheets give a novel blend of properties that upgrade their exhibition and flexibility.

In contrast with metal sheets, epoxy glass fiber sheets are altogether lighter while keeping up with practically identical strength and firmness. This weight decrease can prompt lower transportation costs and further develop eco-friendliness in applications like aviation and auto fabricating. Moreover, epoxy glass fiber sheets offer better erosion opposition thought about than metals, making them reasonable for use in cruel conditions without the requirement for defensive coatings.

When contrasted with plastic sheets, epoxy glass fiber sheets offer higher mechanical strength and layered steadiness. While plastics might show more prominent adaptability, epoxy glass fiber sheets give a better unbending nature and protection from misshapen under load. Besides, epoxy glass fiber sheets offer better electrical protection properties analyzed than most plastics, making them ideal for applications requiring dependable protection.

Contrasted with composite materials supported with elective strands like carbon fiber or aramid fiber, epoxy glass fiber sheets are commonly more financially savvy while as yet giving phenomenal mechanical properties. While carbon fiber composites offer higher solidarity-to-weight proportions, they are much of the time more costly and can be more fragile. Aramid fiber composites, then again, offer high-effect obstruction yet may not give a similar degree of layered security and temperature opposition as epoxy glass fiber sheets.

Conclusion and Call to Action

Epoxy Resin Sheets are a highly reliable and versatile material choice for a broad range of industrial applications. If you're looking for a material that combines strength, insulation, and durability, consider using epoxy glass fiber sheets for your next project. We are a professional manufacturing supplier with GMP factory certification, offering a large inventory and complete certificates. We support OEM, ensure fast delivery, and provide tight packaging to meet diverse client needs. For collaboration, please contact us at info@jhd-material.com, and we will be ready to meet your specific requirements and foster a successful partnership.

By understanding the basic properties and uses of epoxy glass fiber sheets like G10 and FR-4, businesses can better appreciate why these materials are often chosen for applications that require durability and electrical insulation. Their broad utility across industries underscores their importance in modern manufacturing and engineering sectors.