Study on the influence of epoxy resin structure on the performance of marine coatings

2022-11-07

1. Introduction

China has a vast sea area and rich marine resources. Especially in recent years, the country has been paying more attention to marine development. With the rapid development of marine economy, the shipbuilding industry has also risen. The market prospect of marine ship coatings is very optimistic and the requirements are getting higher and higher. Among them, epoxy resin coating has strong adhesion, excellent rust prevention and water resistance, good mechanical strength and chemical resistance, and plays an important role in ship protection, especially in the hull, waterline, deck and other parts. It is considered to be one of the pillar products in the marine ship coating industry.

However, with the continuous improvement of the performance standards of marine coatings in recent years, it is required that the epoxy resin used be improved in heat resistance, high toughness, moisture resistance and other aspects to achieve high-performance. However, due to the large intermolecular force of epoxy resin, the aggregate is rigid. In addition, the molecular chains can be arranged orderly, forming highly crystalline, brittle at room temperature, and poor impact performance. Therefore, it is urgent to understand and master the characteristics of epoxy resin with different structures, especially the impact performance, which is of great significance for the design and development of epoxy resin coatings for marine ships.

In this paper, the hardness, adhesion and impact properties of the coatings are investigated by selecting epoxy resins with different structures, including bisphenol A, hydrogenated bisphenol A, bisphenol F and mixed epoxy resins, and using flexible polyether amine as the curing agent, so as to obtain the relationship between different epoxy resin structures and coating properties, thus providing a theoretical basis for the development and application of epoxy coatings for marine ships.

2. Experiment

a) Raw Material

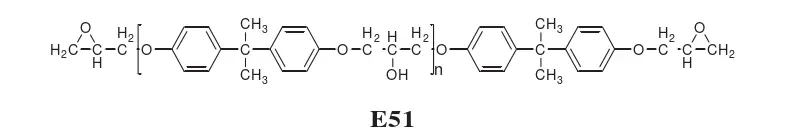

Phenol A epoxy resin E51: epoxy value 0.51; Hydrogenated bisphenol A epoxy resin ST3000: epoxy value 0.43; Bisphenol F epoxy resin CYDF170: epoxy value 0.60; Mixed epoxy resin TDE85: epoxy value 0.85; D230: amine active hydrogen equivalent 60g/eq; Acetone.

b) Experimental Methods

i. Coating Preparation

According to the formula shown in Table 1, weigh a certain amount of resin and curing agent, mechanically stir them at room temperature until the system is uniform, vacuum defoaming, and then use 100 μ M paint film applicator applies a layer of paint film on the steel plate (polished and cleaned with acetone) for adhesion test; The remaining coating is poured into the mold (about 8mm) with steel plate at the bottom (polished and cleaned with acetone) for hardness and impact resistance tests. The properties were tested after curing at room temperature for 7 days.

Table 1 The influence of epoxy resin structure on coating performance

Epoxy Resin Dosage of Curing Agent / g | E51 | ST3000 | CYDF170 | TDE85 |

D230 | 36.7 | 31.0 | 43.2 | 61.2 |

Note: All epoxy resin dosage is 100g, and active H: epoxy base=1.2:1

ii. Performance Testing

Test equipment and test methods for various characteristics of cured resin coating are shown in Table 2.

Table 2 Coating Performance Test

Test Items | Instrument and Equipment | Test Method |

Film Thickness | Qnix4200 metal coating thickness gauge | |

Drying Time | GZT-1 drying time recorder | ASTM D 5895-2003 |

Hardness | Shore hardness tester | GB2411-1980(1989) |

Adhesion | PosiTest AT adhesion test | |

Flexibility | QTX film flexibility tester | GB/T 1731-1993 |

Impact Performance | QCJ paint film impactor | GB-T1732-1993 |

3. Results and Discussion

a) Drying Time

The drying time of the resin directly affects the construction performance of the coating. In this paper, the drying time of four different epoxy resins was investigated with D230 as curing agent, as shown in Table 3. The results showed that the curing rate of mixed epoxy resin was very fast because it contained three epoxy groups, and it could be dried in three hours; The curing of hydrogenated bisphenol A epoxy resin is very slow, and it still cannot be surface dried after 24h.

Table 3 Effect of different epoxy resins on drying time

Curing Agent | Surface drying time/h | Dry time/h |

E51 | 7 | 12 |

ST3000 | ≥24 | >24 |

CYDF170 | 8.5 | 15 |

TDE85 | 1.5 | 3 |

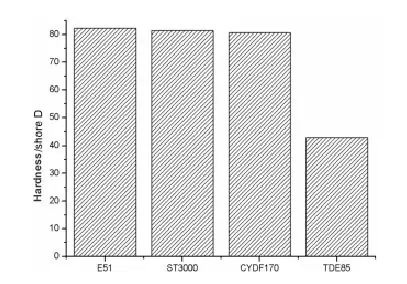

b) Hardness

The film hardness is one of the most concerned performance indicators of users and coating manufacturers, and also one of the most important physical properties of marine ship coatings. It reflects the ability of one material to resist the indentation, scratch, scratch and penetration of another material. For the four epoxy resins investigated in this paper, the hardness of cured resin is shown in Figure 2. The hardness of E51, CYDF-170 and ST-3000 is about 80 Shore D. This is because they are all bisphenol epoxy resins. The hydroxyl group on the molecular chain can greatly improve the intermolecular force, and the corresponding cohesive energy is also large, so the hardness of the cured resin is also high. However, when the epoxy resin is TDE-85, because there is no rigid structural group of benzene ring on the molecular chain, and the intermolecular force is relatively small, the hardness is lower than that of bisphenol epoxy resin, only 43 Shore D.

Fig. 2 Hardness of cured resin obtained by reaction of curing agent D230 with different epoxy resins

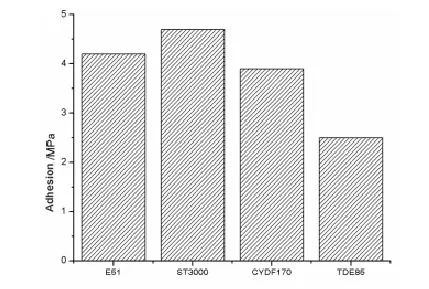

c) Adhesion

For marine coatings, anti-corrosion performance is an important indicator, and the adhesion between polymer coatings and metals is a prerequisite for the full play of anti-corrosion function. Therefore, in this paper, the coating adhesion of cured epoxy resins with four different structures is studied, and the results are shown in Figure 3. The maximum adhesion of hydrogenated bisphenol A epoxy resin ST3000 is 4.7MPa, followed by bisphenol A epoxy resin E51 and bisphenol F epoxy resin CYDF170, about 4MPa, while the adhesion of mixed epoxy resin TDE85 is only 2.5MPa. When the coating is attached to the metal substrate, a chemically active attachment center is required. Polar groups, especially hydroxyl and carboxyl groups, can form such chemically active attachment centers [10]. It can be seen from Figure 1 that both bisphenol epoxy resin and mixed epoxy resin have a certain amount of polar groups, but TDE85 has a very fast curing speed. With the progress of curing and cross-linking reaction, the molecular chain movement becomes more and more difficult, and it cannot diffuse to the surface of the steel plate. The polar groups cannot interact with the surface of the steel plate. There are few polar groups effectively attached, so the adhesion is very low. The curing speed of hydrogenated bisphenol A epoxy resin is the slowest, the molecular chain has enough time to move to the surface of the steel plate, and the most effective polar groups are attached, with the greatest adhesion.

Fig. 3 Adhesion of curing resin obtained by curing agent D230 reacting with different epoxy resins

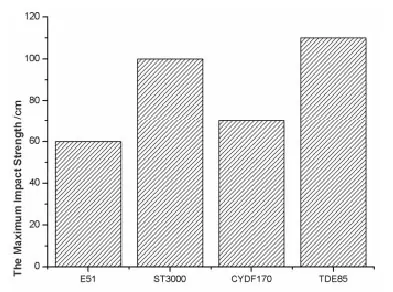

d) Impact resistance

The biggest disadvantage of epoxy resin is its brittleness and poor toughness, which limits its application in the parts requiring high impact resistance and fracture resistance on ships. In this paper, a 2kg heavy hammer was dropped on the test panel to investigate the impact performance of cured epoxy coatings with different structures. The results are shown in Figure 4. The maximum impact height represents the maximum height that does not cause coating damage after the impact of the heavy hammer. For bisphenol A epoxy resin E51, due to the existence of the rigid group of benzene ring and hydroxyl group on its molecular chain, the cohesion energy is large. Even if the curing agent is flexible polyether amine D230, its molecular chain is short and plays little role. Therefore, the impact performance of the coating obtained after the reaction and curing of the two is the worst, with the maximum impact height of only 60cm. Compared with E51, the group connecting two benzene rings in the molecular chain of bisphenol F epoxy resin CYDF170 changes from isopropyl group to methylene group, which improves the activity of the molecular chain and slightly improves the impact property compared with E51. The hydrogenated bisphenol A epoxy resin ST3000 has only alicyclic ring in the main chain, which has small rigidity, good impact performance and impact height of 100cm. After curing, the mixed epoxy resin TDE85 has low cohesive energy, and the alicyclic group can effectively improve the toughness of the cured product. Therefore, the impact performance is optimal, and the impact height is 110cm.

Fig. 4 Impact properties of cured resin obtained by curing agent D230 reacting with different epoxy resins

4. Conclusion

(1) With D230 as curing agent, the hardness of bisphenol epoxy resin E51, ST3000 and CYDF170 can reach 80 Shore D after curing due to the large cohesive energy; The mixed epoxy resin TDE85 is only 43 Shore D after curing.

(2) For the four epoxy resins studied in this paper, the size relationship of adhesion is ST3000>CYDF170>E51>TDE85, and the adhesion of ST3000 and D230 to polished steel plate after curing can reach 4.7MPa.

(3) When D230 is used as curing agent, TDE85 has the best impact property and E51 has the worst impact property.