What Is a Bakelite Sheet Used for?

2024-07-16 15:56:27

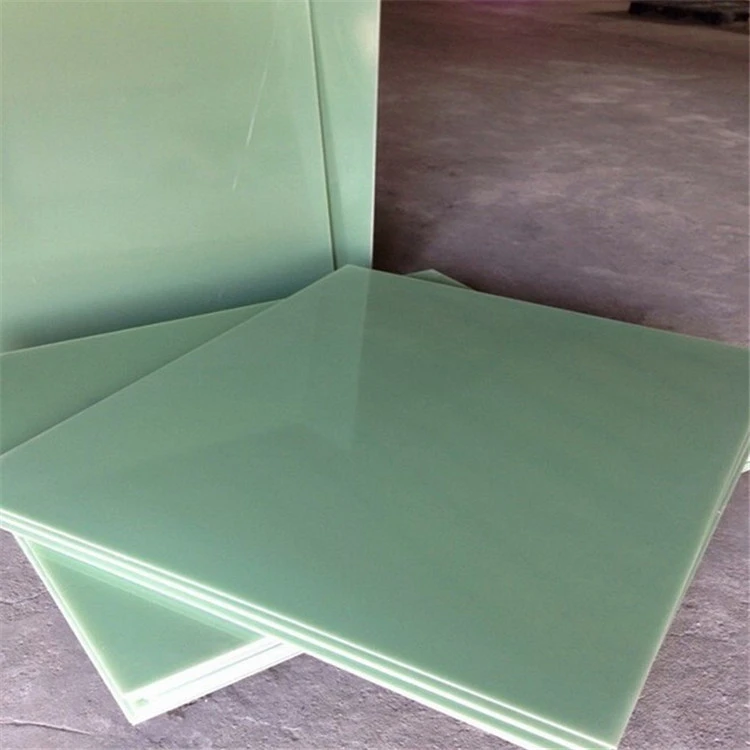

Because of their special qualities, bakelite sheets—made from the first synthetic plastic—have a lot of uses. These sheets have a reputation for having superior mechanical strength, heat resistance, and electrical insulation. Which are used in many sectors and are now vital parts of many systems and products. We shall examine the applications of sheets in this blog, answering frequently asked issues and emphasizing their significance in contemporary technology.

What Are the Common Applications of Bakelite Sheets?

Bakelite sheets are used in many sectors because of their versatility and toughness. Applications requiring great heat resistance and electrical insulation are where they are especially helpful.In this part, we'll discuss some of the most popular applications for Bakelite sheets:they are mostly used as electrical insulation. They are perfect for insulating electrical components and preventing short circuits since they are non-conductive. Numerous electrical applications make use of bakelite sheets, such as:Boards Most printed circuit boards (PCBs) are made of bakelite sheets. Bakelite's insulating qualities offer a sturdy mounting platform for circuits while shielding electronic components from electrical interference.Which are widely used in electrical switches, sockets, and other connectors to guarantee dependability and safety.Because these parts need to withstand high temperatures and electrical loads, bakelite is an excellent choice.Which are used as insulation to protect the components and windings of electric motors. As a result, the motor will function safely and effectively and there will be no electrical shorts.Bakelite sheets are known for not bending or losing their properties when heated to high temperatures. As a result, they can be used in a variety of heat-resistant applications:Cooking Utensils The handles and knobs of cooking utensils like pots and pans are frequently constructed using it. Even when the utensil is heated, these components remain safe to handle and cool to the touch because of the material's heat resistance.Bakelite sheets are used in high-temperature machinery found in the industrial sector. They guarantee the machinery operates smoothly and securely by offering thermal insulation and protecting delicate elements from heat damage.

Distributor caps and ignition systems, among other automotive components, are made of sheets. Due to its ability to withstand high temperatures and electrical currents, bakelite is an excellent material for these components.Due to their mechanical strength, which are ideal for applications requiring materials that are long-lasting and resistant to impacts:Handles for tools like hammers, pliers, and screwdrivers are made from the products. Due to the material's strength and resistance to wear, the handles will remain intact and comfortable to use over time. sheets are used to build structural parts in engineering and construction that need to be strong and rigid. These sheets provide stability while supporting significant loads in a variety of applications.Bakelite-sheet protective covers for machinery and equipment are also available. These covers, which shield delicate components from physical damage and the elements, extend the equipment's lifespan.

How Are Bakelite Sheets Manufactured?

If you learn how Bakelite sheets are made, you will have a better understanding of their unique properties and numerous applications. There are a number of steps in the production process, each of which affects the final product's performance and quality: Reaction of Phenol and Formaldehyde A thermostable phenolic resin that is used to make it is produced when phenol and formaldehyde react. Bakelite sheets, a material that can withstand heat and last a long time, are the result of this chemical reaction. Constructing a Sheet: The mechanical properties of the phenolic resin can be improved by adding fillers like cotton fabric, asbestos, or wood flour. After being heated and pressed, the mixture is spread out into sheets of the desired thickness. Curing The sheets are dried at a high temperature and pressure in molds. The resin polymerizes and hardens as a result of this process, creating a material that is both rigid and stable. The sheets will not have the required strength, resistance to heat, or electrical insulation if the curing process is not carried out. Which are finished by trimming, sanding, and polishing after being baked in molds. This is done to control quality. These actions will guarantee that the sheets have a smooth surface and meet the requirements. The mechanical strength, electrical insulation, and heat resistance of the sheets are examined during quality control tests. There are numerous uses for bakelite sheets. It is necessary to cut the sheets into a variety of sizes, improve their surface, and incorporate colors or patterns. Which can be used in a wide range of industries and applications due to their adaptability. Why are bakelite sheets preferred to other materials? Due to their unique combination of properties, Which are frequently chosen over other materials. This section will discuss the advantages of using Bakelite sheets in a variety of applications as well as the reasons for their popularity: The products provide excellent electrical protection, which is necessary for a variety of applications.Bakelite is an excellent choice for insulating electrical components and preventing short circuits because it does not conduct electricity in the same way that other materials do. Particularly valuable in the electrical and electronics industries is this property.High-intensity which can withstand high temperatures without losing their properties or bending. As a result, they can be used in machinery that needs to be resistant to heat, automotive components, and cooking utensils. Bakelite is favored because it resists heat better than many other materials.Due to their mechanical strength, Bakelite sheets can withstand significant impacts and loads. As a consequence of this, structural components, tool handles, and protective covers may all gain from their use. Bakelite products last longer and require fewer replacements because of its durability.Resistance to Chemicals Bakelite sheets can withstand a variety of chemicals, including acids and bases. They are ideal for use in harsh environments where other materials may degrade or fail due to their chemical resistance. Bakelite, for instance, is frequently utilized in chemically delicate laboratory and industrial equipment.Cost-Effectiveness Compared to other high-performance materials, bakelite sheets are less expensive. Costs are reduced because the production process is relatively simple and effective. Bakelite products are also extremely cost-effective over time due to their long-term durability.Which can be used in a variety of ways. They are simple to mold, machine, and modify to meet particular requirements. Bakelite is an appealing option for designers and manufacturers looking for a dependable and adaptable material due to its adaptability.Where are Sheets being used right now?Due to their durability, sheets are still utilized in a variety of industries. We'll take a look at a few specific uses for the products in this section:In the electrical and electronic industry, sheets are frequently used to insulate connectors, circuit boards, and components. They are crucial to this industry because of their excellent heat resistance and electrical insulation.Radios, kitchen appliances, and other consumer electronics all make use of sheets. These devices are safe and dependable due to the material's heat resistance and electrical insulation.Which are used to make components of industrial electronics like transformers, switchgear, and control panels. Bakelite is an excellent choice because these applications require materials that can withstand electrical loads and high temperatures.The sheets are utilized because some automotive components need to be able to withstand heat and electrical current. The dashboard's components, ignition systems, and distributor caps are all included in this.Significance Early automobile designs frequently included bakelite gearshift knobs and steering wheels. Bakelite is still utilized in specific applications where its properties are advantageous, despite the fact that modern materials have largely replaced it in these applications.In the manufacturing and industrial sectors, sheets are used to make machine parts, protective covers, and insulation materials. The material is suitable for harsh industrial environments because of its durability, resistance to chemicals, and heat resistance.Machinery Parts the products are used in parts of machinery that need to withstand high temperatures and mechanical stress. Materials that are not only long-lasting but also durable are required for components like bearings, gears, and seals.Machines and delicate equipment are protected by bakelite covers. By shielding the equipment from heat, chemical exposure, and physical damage, these covers extend its lifespan.Products for the Consumer Market A wide range of consumer goods, including vintage collectibles and kitchenware, are also made with sheets. The material is suitable for everyday items that must withstand regular use and high temperatures due to its heat resistance and durability.sheets are used to make handles and knobs for pots, pans, and other cooking utensils in the kitchen. The material has a secure, long-lasting grip and is cool to the touch.Bakelite has been making jewelry and other collectibles for a very long time. Due to its distinctive aesthetic and historical significance, vintage Bakelite jewelry is highly sought after. Due to the variety of the material and its ease of shaping, numerous designs and plans were possible.

References

1. The Bakelite Story and Applications. (n.d.). taken from the Science History Institute website (https://www.sciencehistory.org/historical-profile/leo-hendrik-baekeland-and-bakelite)

2. The Substance That Transformed the Globe: Bakelite. (2023). taken from the website of the American Chemical Society (https://www.acs.org/content/acs/en/education/whatischemistry/landmarks/bakelite.html).

3. Bakelite Sheet Applications. (2022). obtained obtained via [ResearchGate] (https://www.researchgate.net/publication/322658616_Applications_of_Bakelite_Sheets)

4. Industrial Applications of Phenolic Resins. (2021). Excerpted from https://www.constructionspecifier.com/phenolic-resins-in-industrial-applications/ on [Construction Specifier]

5. Bakelite's Versatility in Contemporary Manufacturing. (2020). The adaptability of bakelite in modern production is a resource taken from [Industry Week] (https://www.industryweek.com/technology-and-iiot).