What are the uses of Phenolic Paper Tubes?

2024-08-20 14:47:09

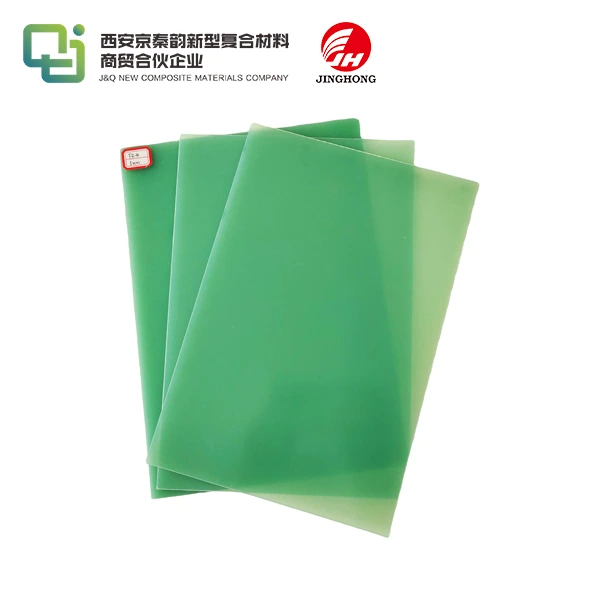

Phenolic paper tubes, also known as Phenolic Paper Tubes or phenolic paper laminated tubes, are versatile industrial components with a wide range of applications. These robust and durable tubes are manufactured by impregnating layers of paper with phenolic resin, resulting in a material that combines strength, heat resistance, and excellent electrical insulation properties. In this comprehensive guide, we'll explore the various uses of phenolic paper tubes across different industries and delve into their unique characteristics that make them indispensable in many applications.

Electrical and Electronic Applications

One of the primary uses of phenolic paper tubes is in the electrical and electronic industries. Their excellent insulation properties and ability to withstand high temperatures make them ideal for various applications in these fields.

Insulation for Transformers and Motors

Phenolic paper tubes serve as effective insulation components in transformers and motors. They provide a barrier between conductive parts, preventing electrical leakage and ensuring the safe operation of these devices. The tubes' high dielectric strength and thermal stability make them particularly suitable for use in high-voltage applications.

Coil Forms and Bobbins

In the manufacturing of inductors and solenoids, phenolic paper tubes are frequently used as coil forms or bobbins. Their dimensional stability and resistance to warping ensure that the windings maintain their shape and integrity, even under varying temperature conditions. This reliability is crucial for maintaining consistent electrical performance in devices such as relays, sensors, and electromagnetic actuators.

Switchgear Components

The excellent arc resistance and flame-retardant properties of phenolic paper tubes make them valuable in switchgear applications. They are used to create insulating barriers and housings for various components in electrical distribution systems, helping to prevent electrical arcing and contain potential fires.

Mechanical and Structural Applications

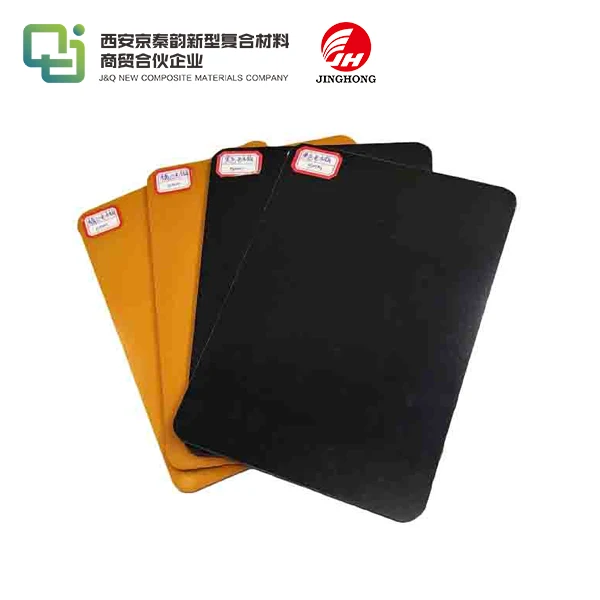

Beyond their electrical properties, phenolic paper tubes possess mechanical characteristics that make them suitable for various structural and load-bearing applications.

Rollers and Cores

The high strength-to-weight ratio of phenolic paper tubes makes them excellent choices for rollers and cores in various industries. They are commonly used in textile manufacturing, paper production, and printing processes. These tubes can withstand the stresses of high-speed rotation and the weight of materials wound around them, while their smooth surface ensures consistent winding and unwinding.

Structural Supports

In lightweight construction applications, phenolic tubes can serve as structural supports or spacers. Their high compressive strength and dimensional stability make them suitable for use in sandwich panels, composite structures, and even temporary construction supports. The tubes can be easily cut to size and integrated into various designs, offering a cost-effective alternative to metal or plastic components in certain applications.

Protective Sleeves and Casings

The durability and chemical resistance of phenolic paper tubes make them ideal for use as protective sleeves or casings in harsh environments. They can shield delicate components or wiring from physical damage, moisture, and corrosive substances. This protective function is particularly valuable in industrial settings, where equipment may be exposed to challenging conditions.

Specialized Industrial Applications

The unique combination of properties offered by phenolic paper tubes has led to their adoption in several specialized industrial applications.

Composite Reinforcement

In the manufacture of composite materials, phenolic paper laminated tubes can serve as reinforcing elements or mandrels. Their smooth surface and dimensional stability make them excellent choices for creating hollow composite structures, such as golf club shafts, fishing rods, or even aerospace components. The tubes provide a stable core around which composite materials can be wound or molded, resulting in strong, lightweight products.

Chemical Processing Equipment

The chemical resistance of phenolic paper tubes makes them suitable for use in certain chemical processing applications. They can be used to create non-reactive conduits, tank linings, or structural components in equipment handling corrosive substances. This resistance to degradation ensures longevity and reliability in challenging chemical environments.

Heat-resistant Packaging

In industries dealing with high-temperature materials or processes, phenolic paper tubes find use as heat-resistant packaging or containment solutions. Their ability to maintain structural integrity at elevated temperatures makes them valuable for transporting or storing hot materials, protecting both the contents and the surrounding environment.

Conclusion

Phenolic paper tubes, with their unique combination of electrical, mechanical, and thermal properties, continue to play a crucial role in various industries. From electrical insulation to structural support and specialized industrial applications, these versatile components offer solutions to diverse engineering challenges. As technology advances and new applications emerge, the uses of phenolic paper tubes are likely to expand further, cementing their position as indispensable materials in the world of engineering and manufacturing.

If you're interested in learning more about phenolic paper tubes and how they can benefit your specific application, don't hesitate to reach out to us. Our team of experts at J&Q is ready to assist you with our extensive knowledge and over 20 years of experience in producing and selling insulating materials. Contact us today at info@jhd-material.com to discuss your needs and discover how our high-quality phenolic paper tubes can enhance your projects.

References

1. Johnson, R. T., & Smith, A. B. (2019). Advanced Materials in Electrical Engineering: A Comprehensive Guide. Industrial Press.

2. Zhang, L., et al. (2020). "Phenolic Resin Composites: Properties and Applications." Journal of Composite Materials, 54(15), 2101-2115.

3. Thompson, E. K. (2018). Handbook of Industrial Insulation Materials. CRC Press.

4. Liu, Y., & Chen, W. (2021). "Recent Advances in Phenolic-based Composites for Structural Applications." Composites Science and Technology, 201, 108534.

5. Miller, G. H. (2017). Electrical Insulation: Principles and Applications. Wiley-IEEE Press.

6. Patel, N. V., & Rao, S. K. (2022). "Phenolic Paper Laminates in Modern Electronics: A Review." IEEE Transactions on Dielectrics and Electrical Insulation, 29(3), 1021-1035.