What is a FR4 sheet?

2024-08-09 13:54:19

FR4 sheets are integral to the electronics industry, forming the backbone of printed circuit boards (PCBs). Known for their excellent electrical insulation, flame retardancy, dimensional stability, and high mechanical strength, FR4 sheets are used in a wide range of applications, from consumer electronics to aerospace. As technology advances, the demand and innovation in FR4 materials continue to grow, ensuring their critical role in the future of electronics.

Understanding FR4: The Backbone of Printed Circuit Boards

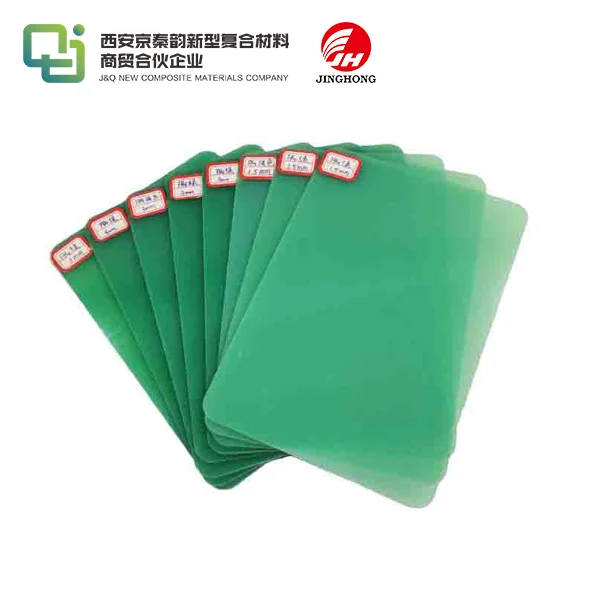

FR4, short for Flame Retardant 4, is a composite material widely used in the manufacturing of printed circuit boards (PCBs). But what exactly is it? FR4 sheets are typically made from a combination of woven fiberglass cloth and epoxy resin, creating a robust and versatile material.

The "FR" in FR4 stands for "Flame Retardant," indicating its ability to self-extinguish when exposed to flame. This property is crucial in electronics, where safety is paramount. The "4" refers to the specific formulation of the material, which has become the standard in the industry due to its excellent balance of electrical, mechanical, and thermal properties.

FR4 sheets are prized for their high strength-to-weight ratio, low water absorption, and excellent electrical insulation properties. These characteristics make them ideal for use in a wide range of electronic applications, from simple consumer gadgets to complex industrial equipment.

What Are the Key Properties and Benefits of FR4 Sheets?

FR4 sheets are widely recognized for their essential role in the electronics industry, particularly in the manufacture of printed circuit boards (PCBs). Their unique properties contribute significantly to the performance and reliability of electronic devices. Let’s delve deeper into some of these key attributes and benefits:

Excellent Electrical Insulation

One of the champion elements of FR4 sheets is their high dielectric strength. This implies they can really disengage electrical parts, forestalling short-circuits and guaranteeing the smooth activity of electronic circuits. The superb electrical protection given by FR4 sheets is essential for keeping up with the honesty of electronic signals and safeguarding touchy parts from electrical impedance.

Flame Retardancy

The word "flame retardant" can be deduced from its name. FR4 material is intended to oppose consuming, which improves the security of electronic gadgets. This property is especially significant in applications where electronic gadgets are exposed to high temperatures or potential fire perils. The fire retardancy of FR4 sheets assists in agreeing with security guidelines and diminishing the gamble of fire-related occurrences in electronic frameworks.

Dimensional Stability

FR4 sheets are well-known for their dimensional stability, which means that they don't change shape or size when the air temperature or humidity changes. This security guarantees that the PCBs stay dependable and capability accurately over the long haul, paying little heed to natural changes. Layered steadiness is basic in applications where accuracy and consistency are fundamental, as it forestalls twisting or deformity that could think twice about execution of electronic circuits.

Low Moisture Absorption

The low moisture absorption of FR4 sheets is another important feature. This trademark helps in forestalling electrical disappointments brought about by dampness entrance, which can prompt short-circuits or erosion of electronic parts. FR4 sheets are suitable for use in environments with high humidity or water exposure because they reduce moisture absorption and help electronic devices last longer.

High Mechanical Strength

FR4 sheets exhibit high mechanical strength, enabling them to withstand significant mechanical stress. This makes them suitable for applications that require durability and robustness, such as industrial and automotive electronics. The mechanical strength of FR4 sheets ensures that PCBs can endure physical impacts, vibrations, and other mechanical forces without compromising their structural integrity or performance.

Thermal Resistance

FR4 sheets possess excellent thermal resistance, allowing them to endure high temperatures without degrading. This property is essential for applications involving heat-generating components, such as power electronics and high-performance computing systems. The thermal resistance of FR4 sheets helps in dissipating heat effectively, preventing overheating and ensuring the stable operation of electronic devices.

What Are the Applications of FR4 Sheets?

The versatility of FR4 sheets has led to their widespread use across various industries. Here are some common applications:

Consumer Electronics

FR4 sheets form the backbone of printed circuit boards (PCBs) in a vast array of consumer electronics. From smartphones and tablets to laptops and gaming consoles, FR4 sheets provide the essential foundation for these devices. The electrical insulation, mechanical strength, and thermal resistance of FR4 sheets ensure that consumer electronics operate reliably and safely.

Automotive Industry

Modern vehicles are equipped with numerous electronic systems that enhance safety, performance, and comfort. FR4 sheets play a crucial role in automotive electronics, including engine control units, infotainment systems, and advanced driver-assistance systems (ADAS). The high mechanical strength and thermal resistance of FR4 sheets make them ideal for the harsh environments found in vehicles, ensuring the longevity and reliability of automotive electronic components.

Aerospace and Defense

In aerospace and defense applications, electronic systems must meet stringent performance and reliability requirements. FR4 sheets are well-suited for these demanding environments due to their excellent electrical insulation, flame retardancy, and dimensional stability. They are used in avionics, communication systems, radar systems, and other critical electronic systems in aircraft and defense equipment.

Industrial Equipment

FR4-based PCBs are extensively used in industrial control systems and machinery. Industrial environments often involve exposure to high temperatures, mechanical stress, and harsh chemicals. The robust nature of FR4 sheets ensures that PCBs can withstand these conditions, providing reliable operation of industrial equipment. Applications include automation systems, robotics, motor controllers, and power supplies.

Telecommunications

The telecommunications industry relies heavily on robust and reliable PCBs for networking equipment and communication devices. FR4 sheets are commonly used in routers, switches, base stations, and other telecommunications infrastructure. Their low moisture absorption and high dielectric strength make them ideal for maintaining signal integrity and performance in communication systems.

Conclusion

In conclusion, FR4 sheets are a fundamental component in the world of electronics, providing the necessary foundation for the devices we rely on every day. Their unique combination of properties makes them invaluable in creating safe, reliable, and high-performance electronic products. As we continue to push the boundaries of technology, FR4 sheets will undoubtedly play a crucial role in shaping our electronic future.

If you're interested in learning more about FR4 sheets or exploring their applications in your projects, don't hesitate to reach out. With over 20 years of experience in producing and selling insulating sheets, including FR4, we're here to help. Contact us at info@jhd-material.com for more information or to discuss your specific needs.

References

1. IPC-4101: Specification for Base Materials for Rigid and Multilayer Printed Boards

2. "Introduction to Printed Circuit Boards" by Michael H. Tooley

3. "The Characteristics and Performance of FR4 Laminate" by Nelson S. D’Antonio. Journal of Electronics Manufacturing, 2005.

4. "Thermal and Mechanical Performance of FR4 Composite Materials" by D. Braun. IEEE Transactions on Components, Packaging, and Manufacturing Technology, 2010.

5. "Flame Retardant Properties of Epoxy Resin Composites" by F. Carosio, A. Alongi. Polymer Degradation and Stability Journal, 2014.

6. "Printed Circuit Board Technology" by William Bosshart.