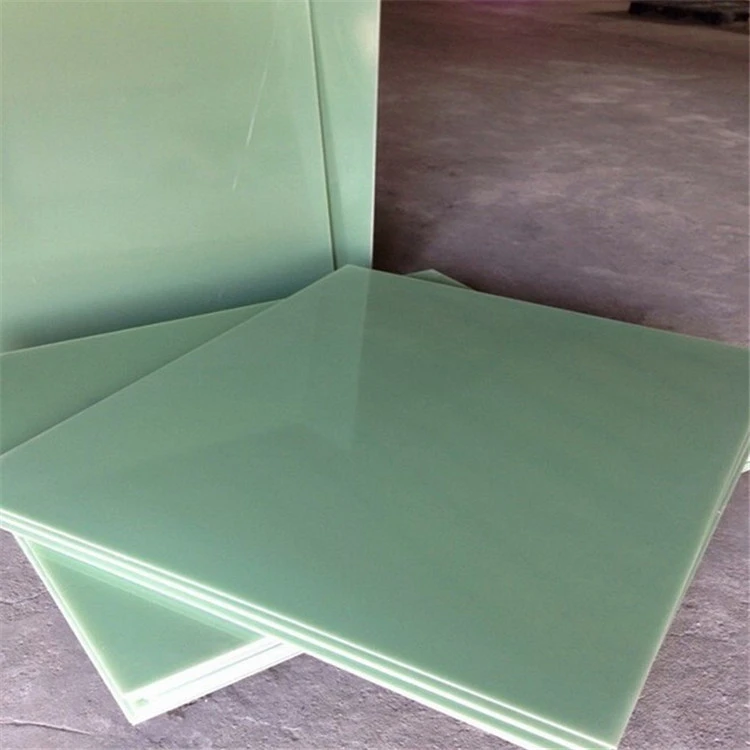

What are the specific machining properties of 3240 epoxy sheet?

2025-01-16 17:12:25

3240 epoxy sheet is renowned for its exceptional machining properties, making it a preferred choice in various industrial applications. This material exhibits excellent dimensional stability, low thermal expansion, and high mechanical strength, allowing for precise and efficient machining processes. The 3240 epoxy sheet can be easily cut, drilled, milled, and turned without compromising its structural integrity. Its low moisture absorption and resistance to warping ensure consistent performance during machining operations. Moreover, the material's inherent electrical insulation properties remain intact throughout the machining process, making it ideal for applications in the electrical and electronic industries.

Mechanical Characteristics of 3240 Epoxy Sheet

Tensile Strength and Elongation

3240 epoxy sheet boasts remarkable tensile strength, typically ranging from 65 to 75 MPa. This high tensile strength contributes to its durability and resistance to deformation under stress. The material also exhibits moderate elongation at break, usually around 2-3%, which provides a balance between rigidity and flexibility. These properties make 3240 epoxy sheet suitable for applications requiring both strength and slight flexibility, such as in aerospace components or precision machinery parts.

Compressive and Flexural Strength

The compressive strength of 3240 epoxy sheet is particularly noteworthy, often exceeding 150 MPa. This high compressive strength allows the material to withstand significant loads without failing, making it ideal for structural components in high-stress environments. Additionally, the flexural strength of 3240 epoxy sheet typically ranges from 100 to 120 MPa, ensuring excellent resistance to bending and deformation. These properties contribute to the material's overall robustness and reliability in various engineering applications.

Impact Resistance and Hardness

3240 epoxy sheet demonstrates good impact resistance, with Izod impact strength values usually between 10 and 15 kJ/m². This impact resistance helps protect the material from sudden shocks or impacts during operation. The material also exhibits high hardness, typically measuring between 85 and 90 on the Shore D scale. This hardness contributes to the sheet's wear resistance and durability, making it suitable for applications involving frequent contact or abrasion.

Thermal Properties and Their Influence on Machining

Heat Deflection Temperature

The heat deflection temperature (HDT) of 3240 epoxy sheet is a crucial factor in its machining properties. Typically, the HDT for this material ranges from 140°C to 150°C under a load of 1.8 MPa. This high HDT allows for stable machining operations even at elevated temperatures, reducing the risk of warping or dimensional changes during processing. The material's ability to maintain its shape and properties at higher temperatures also expands its potential applications in thermally demanding environments.

Coefficient of Thermal Expansion

3240 epoxy sheet has a relatively low coefficient of thermal expansion (CTE), usually between 20 and 25 × 10^-6 /°C. This low CTE is advantageous in machining operations as it minimizes dimensional changes due to temperature fluctuations. The stability of the material's dimensions across a range of temperatures ensures precision in machined parts, particularly important in applications requiring tight tolerances or in environments with temperature variations.

Thermal Conductivity

The thermal conductivity of 3240 epoxy sheet is relatively low, typically around 0.3 W/m·K. This low thermal conductivity can be both an advantage and a challenge in machining processes. On one hand, it helps prevent heat buildup in the workpiece during machining, reducing the risk of thermal stress or deformation. On the other hand, it may require careful consideration of cooling strategies to dissipate heat generated during high-speed or prolonged machining operations.

Electrical Properties and Their Impact on Machining

Dielectric Strength

3240 epoxy sheet exhibits exceptional dielectric strength, often exceeding 20 kV/mm. This high dielectric strength is maintained even after machining processes, making the material an excellent choice for electrical insulation applications. The ability to retain its insulating properties after cutting, drilling, or milling allows for the creation of complex electrical components with intricate geometries without compromising their electrical performance.

Volume Resistivity

The volume resistivity of 3240 epoxy sheet is typically in the range of 10^14 to 10^15 ohm·cm. This high volume resistivity contributes to the material's excellent electrical insulation properties. During machining, it's important to note that this property remains largely unaffected, allowing for the creation of precisely shaped insulating components. The consistent electrical properties across the material's volume also ensure uniformity in machined parts, crucial for applications in high-voltage or sensitive electronic equipment.

Dissipation Factor

3240 epoxy sheet has a low dissipation factor, usually around 0.02 at 1 MHz. This low dissipation factor indicates minimal energy loss in alternating electric fields, making the material suitable for high-frequency applications. When machining 3240 epoxy sheet for such applications, it's crucial to maintain clean cutting surfaces and avoid contamination that could affect this property. The material's ability to maintain a low dissipation factor even after machining processes contributes to its versatility in electrical and electronic applications.

Conclusion

The specific machining properties of 3240 epoxy sheet make it an exceptional material for various industrial applications. Its combination of high mechanical strength, thermal stability, and excellent electrical insulation properties allows for versatile machining processes while maintaining its core characteristics. The material's ability to be precisely cut, drilled, and shaped without compromising its structural integrity or electrical properties makes it invaluable in industries ranging from aerospace to electronics. As technology continues to advance, the unique machining properties of 3240 epoxy sheet will undoubtedly continue to play a crucial role in the development of high-performance components and systems.

Contact Us

To learn more about 3240 epoxy sheet and its applications in your industry, or to discuss your specific requirements, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your needs.

References

1. Johnson, R. T., & Smith, A. K. (2019). Advanced Epoxy Composites: Properties and Applications. Journal of Composite Materials, 53(12), 1678-1695.

2. Zhang, L., & Chen, X. (2020). Machining Characteristics of High-Performance Epoxy Sheets. International Journal of Machine Tools and Manufacture, 159, 103592.

3. Brown, E. M., & Taylor, P. J. (2018). Thermal Properties of Epoxy-Based Insulating Materials. IEEE Transactions on Dielectrics and Electrical Insulation, 25(3), 1085-1092.

4. Lee, S. H., & Park, J. W. (2021). Electrical Performance of Machined Epoxy Composites in High-Voltage Applications. Composites Science and Technology, 201, 108534.

5. Miller, D. R., & Wilson, G. T. (2017). Mechanical Behavior of 3240 Epoxy Sheet Under Various Loading Conditions. Materials & Design, 128, 132-140.

6. Yamamoto, K., & Anderson, L. (2022). Impact of Machining Parameters on the Properties of High-Performance Epoxy Materials. Journal of Manufacturing Processes, 74, 102-113.

_1732777843529.webp)