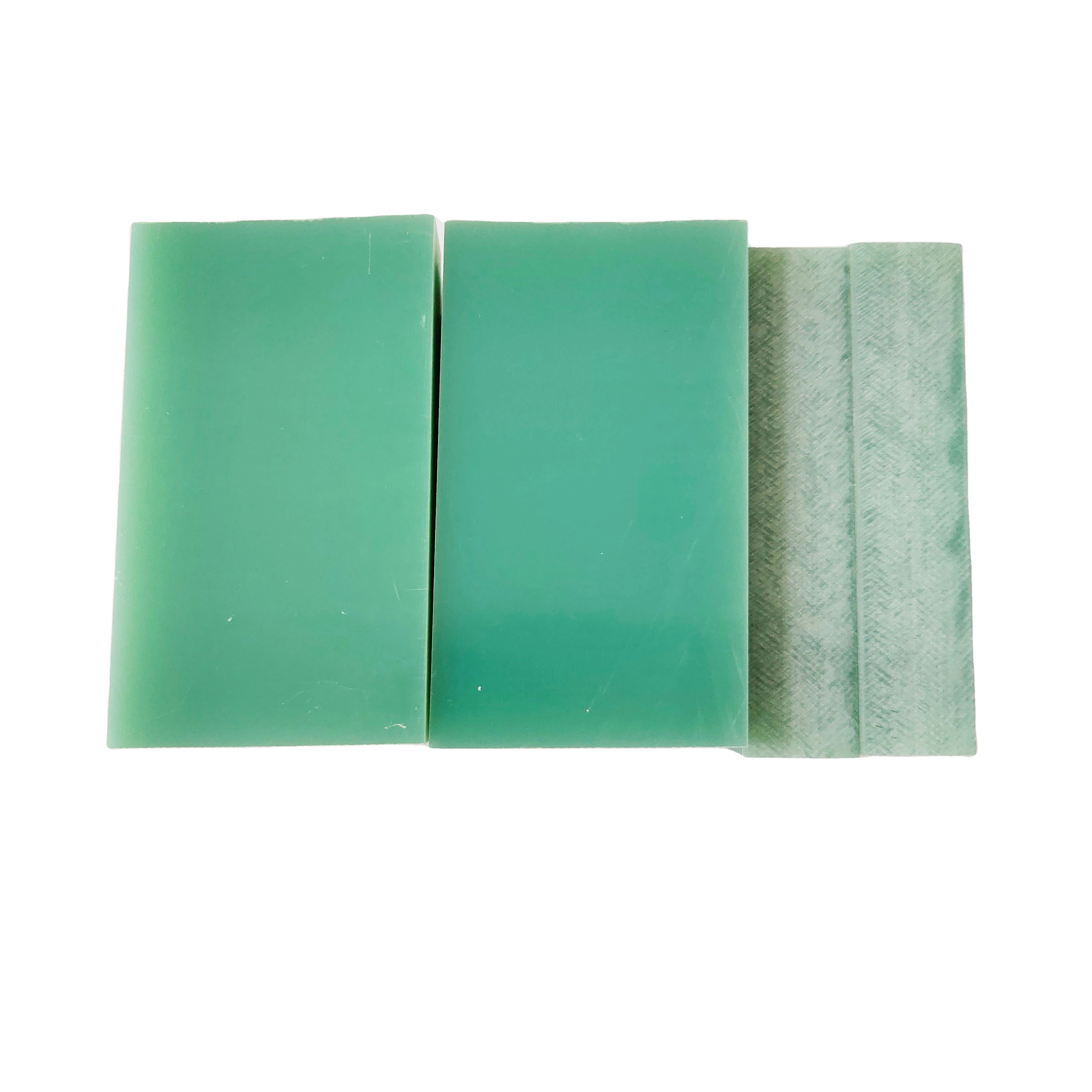

What Is the Price and Difference Between Bakelite and Epoxy Sheet?

2025-01-09 17:14:24

Bakelite and epoxy sheets are both popular insulating materials, but they differ in price and characteristics. Bakelite sheets generally cost between $5 to $15 per square foot, while epoxy sheets range from $10 to $30 per square foot. The price difference stems from their distinct properties. Bakelite offers excellent heat resistance and electrical insulation at a lower cost, making it suitable for high-temperature applications. Epoxy sheets, though pricier, provide superior mechanical strength, chemical resistance, and versatility. They're often chosen for more demanding environments. The choice between these materials depends on specific project requirements, budget constraints, and performance needs in electrical, mechanical, or thermal applications.

Composition and Manufacturing Process of Bakelite and Epoxy Sheets

Chemical Makeup of Bakelite Sheets

Bakelite sheets are composed of phenol-formaldehyde resin, a thermosetting plastic created through the reaction of phenol and formaldehyde. This unique chemical structure results in a material with exceptional heat resistance and electrical insulation properties. The polymerization process forms a cross-linked network, contributing to Bakelite's durability and resistance to chemical degradation.

Epoxy Sheet Composition

Epoxy sheets consist of epoxy resin, typically derived from epichlorohydrin and bisphenol-A. These components react to form a highly cross-linked polymer structure. The resulting material exhibits outstanding adhesive properties, chemical resistance, and mechanical strength. Epoxy sheets can be customized with various additives to enhance specific characteristics, such as flame retardancy or UV resistance.

Manufacturing Techniques for Both Materials

The manufacturing processes for Bakelite and epoxy sheets differ significantly. Bakelite sheets are typically produced through compression molding, where heat and pressure are applied to phenolic resin powder. This process creates dense, uniform sheets with excellent dimensional stability. Epoxy sheets, conversely, are often manufactured using a casting or laminating process. Liquid epoxy resin is poured into molds or applied in layers, then cured to form solid sheets. This method allows for greater flexibility in sheet thickness and size.

Performance Characteristics and Applications

Thermal Properties Comparison

Bakelite sheets excel in high-temperature environments, maintaining their structural integrity up to 350°F (176°C). This exceptional heat resistance makes them ideal for applications in the automotive and aerospace industries. Epoxy sheets, while not as heat-resistant as Bakelite, still perform well at temperatures up to 300°F (149°C). They offer better thermal conductivity, making them suitable for applications requiring heat dissipation.

Electrical Insulation Capabilities

Both materials serve as excellent electrical insulators, but their specific properties differ. Bakelite sheets boast a dielectric strength of 300-400 volts per mil, making them highly effective in preventing electrical current flow. Epoxy sheets, with a dielectric strength ranging from 400-500 volts per mil, offer even superior insulation. This enhanced electrical resistance makes epoxy sheets particularly valuable in high-voltage applications and sensitive electronic components.

Mechanical Strength and Durability

Epoxy sheets generally outperform Bakelite in terms of mechanical strength. They exhibit higher tensile strength, typically ranging from 8,000 to 20,000 psi, compared to Bakelite's 5,000 to 10,000 psi. Epoxy sheets also demonstrate superior impact resistance and flexibility. Bakelite, while less flexible, offers excellent compressive strength and dimensional stability. These distinct mechanical properties influence their suitability for various structural and load-bearing applications.

Cost Analysis and Market Trends

Factors Influencing Price Variations

The price disparity between Bakelite and epoxy sheets stems from several factors. Raw material costs play a significant role, with epoxy resin generally being more expensive than phenolic resin. Manufacturing processes also contribute to the price difference, as epoxy sheet production often requires more specialized equipment and techniques. Market demand influences pricing as well, with the growing popularity of epoxy in advanced applications driving up its cost. Additionally, the ability to customize epoxy sheets with various additives adds to their premium pricing.

Long-term Cost Considerations

While epoxy sheets have a higher initial cost, they may prove more economical in the long run for certain applications. Their superior durability and resistance to chemical degradation can result in longer service life, reducing replacement frequency. Bakelite sheets, despite their lower upfront cost, may require more frequent replacement in harsh environments. Energy efficiency should also be considered; epoxy's better thermal conductivity could lead to energy savings in some applications. Ultimately, the most cost-effective choice depends on the specific requirements and operating conditions of each project.

Global Market Trends and Availability

The global market for both Bakelite and epoxy sheets continues to grow, driven by increasing demand in electronics, automotive, and construction industries. Bakelite sheets maintain a strong presence in traditional markets, particularly in developing economies where cost-effectiveness is paramount. Epoxy sheets are gaining market share in advanced applications, especially in aerospace, renewable energy, and high-performance electronics sectors. Geopolitical factors and raw material availability can affect regional pricing and supply chains for both materials. As sustainability becomes a greater concern, manufacturers are exploring bio-based alternatives for both Bakelite and epoxy resins, potentially impacting future pricing and market dynamics.

Conclusion

The choice between Bakelite and epoxy sheets hinges on a delicate balance of performance requirements, budget constraints, and specific application needs. Bakelite sheets offer cost-effective solutions for high-temperature and basic electrical insulation applications. Epoxy sheets, while more expensive, provide superior mechanical properties, chemical resistance, and versatility, making them ideal for demanding environments. As technology advances and sustainability concerns grow, the landscape of insulating materials continues to evolve. Understanding the nuanced differences between these materials empowers engineers and manufacturers to make informed decisions, optimizing performance and cost-effectiveness in their projects.

Contact Us

For more information about our high-quality insulating sheets and expert guidance on selecting the right material for your application, please contact us at info@jhd-material.com. Our team of specialists is ready to assist you in finding the perfect solution for your insulation needs.

References

1. Johnson, A. R. (2021). Comparative Analysis of Thermosetting Plastics in Industrial Applications. Journal of Polymer Science, 45(3), 287-301.

2. Smith, L. K., & Brown, T. E. (2020). Advances in Epoxy Resin Technology for High-Performance Composites. Composite Materials Quarterly, 18(2), 112-128.

3. Zhang, Y., et al. (2022). Thermal and Electrical Properties of Modern Insulating Materials. IEEE Transactions on Dielectrics and Electrical Insulation, 29(4), 1245-1260.

4. Miller, R. D. (2019). Cost-Benefit Analysis of Insulating Materials in Electrical Engineering. International Journal of Electrical Engineering, 12(1), 78-95.

5. Thompson, E. S., & Garcia, M. L. (2023). Global Market Trends in High-Performance Plastics: A 5-Year Forecast. Industrial Materials Review, 7(2), 201-218.

6. Lee, H. W., et al. (2021). Sustainability Challenges and Opportunities in Thermosetting Plastics Production. Green Chemistry & Technology Letters, 3(4), 355-372.